Environment-friendly nano antibacterial wood plastic composite and preparation method thereof

An antibacterial wood and nano technology, applied in the field of wood-plastic materials, can solve the problems of decreased mechanical properties, poor compatibility, easy breeding of bacteria, etc., and achieve the effect of improving antibacterial and antifungal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A preparation method of an environment-friendly nano antibacterial wood-plastic material, comprising the following steps:

[0044] (1), putting the nano-silver-zinc composite material, surfactant and water weighed according to the above-mentioned formula ratio into a grinder, and grinding for 8 hours to obtain a uniformly dispersed nano-silver-zinc composite aqueous solution;

[0045] (2) Pretreatment: Pour the above-mentioned nano-silver-zinc composite aqueous solution and coupling agent into wood chips, stir evenly, and dry at a constant temperature of 60°C to obtain modified wood chips;

[0046] (3), compatibilization treatment: pour the above-mentioned modified sawdust and the toughening agent into the internal mixer together to granulate, and obtain the toughened modified material of sawdust;

[0047] (4) Extrusion: After mixing the above-mentioned wood chip toughening modified material and polypropylene (PP) evenly, extrude with twin-screws, and the extrusion temp...

Embodiment 1

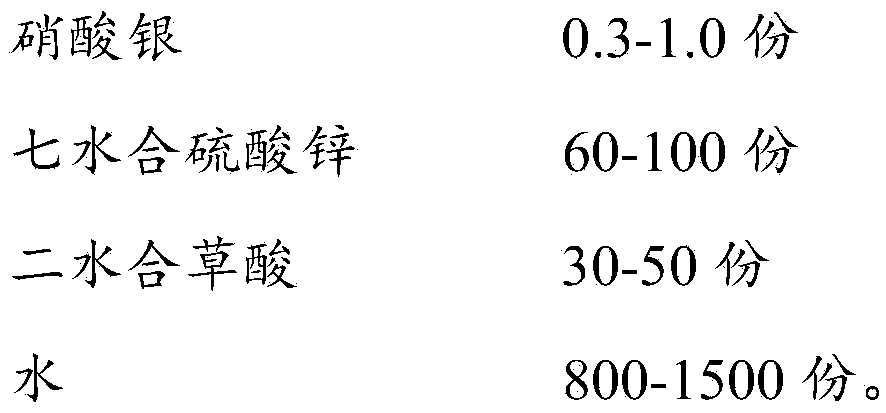

[0058](1) Components and dosage of nano-silver-zinc composite materials

[0059]

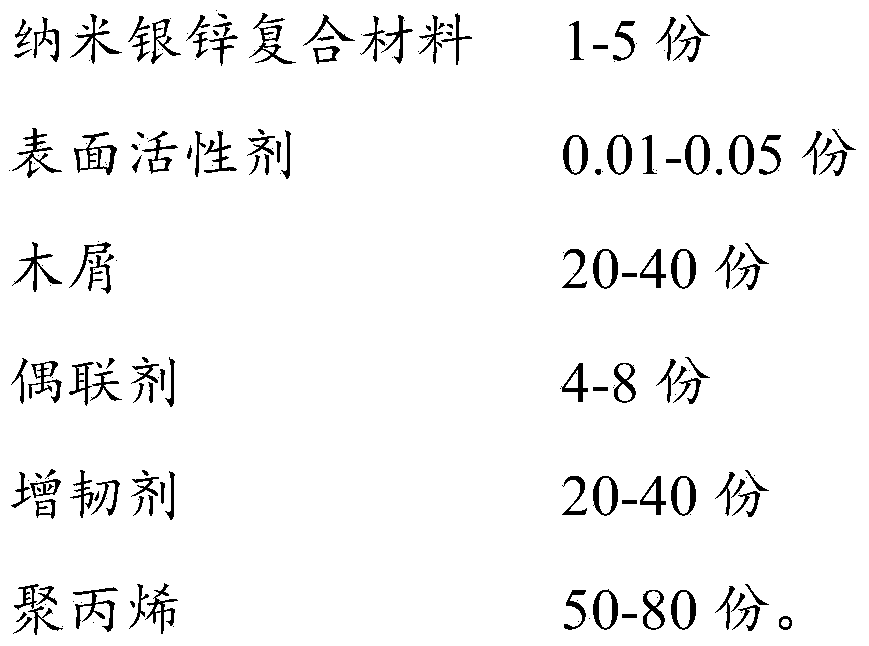

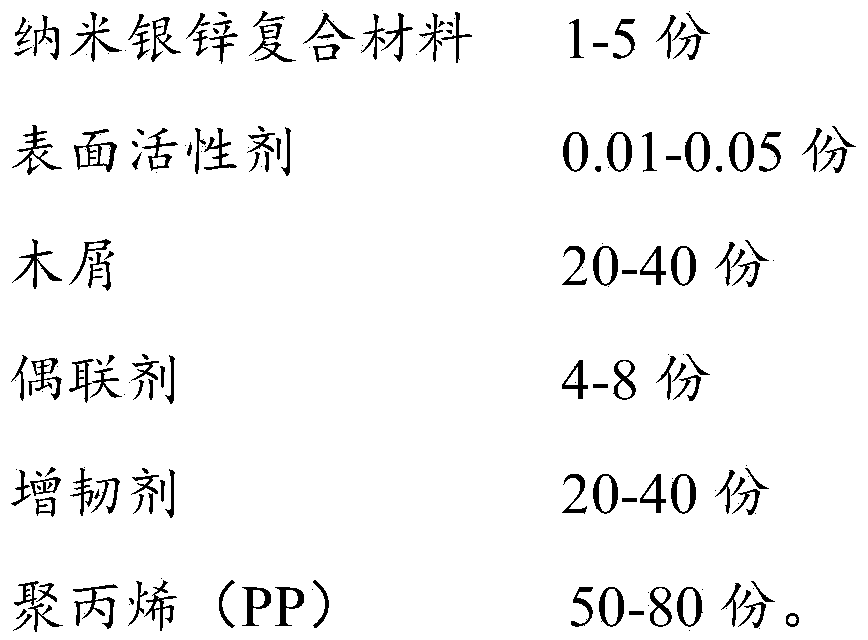

[0060] (2) Components and dosage of environmentally friendly nano-antibacterial wood-plastic materials

[0061]

[0062]

[0063] The prepared environment-friendly nano antibacterial wood-plastic material has undergone relevant tests on mechanical properties and antibacterial and antifungal properties, and the test results of various indicators are shown in Table 1.

[0064] Table 1 Test results of environmentally friendly nano-antibacterial wood-plastic materials

[0065]

[0066] The test results show that the prepared environmentally friendly nano-antibacterial wood-plastic material has good mechanical properties, antibacterial and anti-mildew properties, is not easy to be eaten by insects, and has a long service life.

Embodiment 2

[0068] (1) Components and dosage of nano-silver-zinc composite materials

[0069]

[0070] (2) Components and dosage of environmentally friendly nano-antibacterial wood-plastic materials

[0071]

[0072] The prepared environment-friendly nano antibacterial wood-plastic material has undergone related tests on mechanical properties and antibacterial and antifungal properties, and the test results of various indicators are shown in Table 2.

[0073] Table 2 Test results of environmentally friendly nano-antibacterial wood-plastic materials

[0074]

[0075] The test results show that the prepared environmentally friendly nano-antibacterial wood-plastic material has good mechanical properties, antibacterial and anti-mildew properties, is not easy to be eaten by insects, and has a long service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com