Glass fiber reinforced polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene technology are applied in the field of polymer material modification, which can solve the problems of restricting the application field and application level of glass fiber reinforced polypropylene materials, restricting the selection and application of polypropylene materials, and easily breeding bacteria and mildew. , to achieve the effect of improving antibacterial and mildew resistance, improving hydrophobic performance and high self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13 and comparative example 1-5

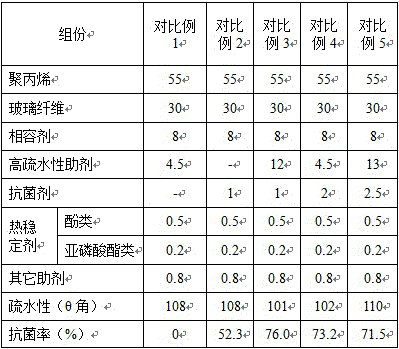

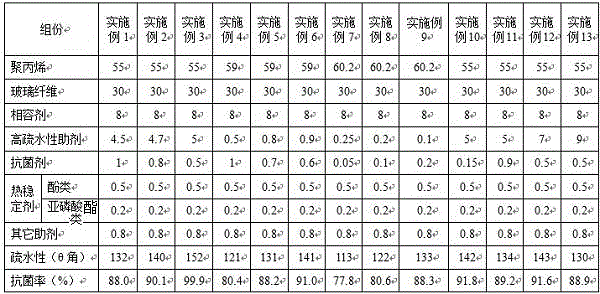

[0050] Examples 1-13 and Comparative Examples 1-5: Preparation of Glass Fiber Reinforced Polypropylene Composition

[0051] According to the ratio in Table 1, polypropylene, compatibilizer, highly hydrophobic additives, antibacterial agents and / or heat stabilizers and / or other additives are passed through a twin-screw extruder with a length-to-diameter ratio of 36-40:1 Melt, mix and disperse at 200°C-230°C, add glass fiber from the side feeding port, extrude and granulate to obtain a glass fiber reinforced polypropylene composition; the resulting glass fiber reinforced polypropylene composition is tested for its hydrophobicity after sample preparation The specific test data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com