Starch-containing biomass cane-like material and preparation method thereof

A biomass and starch technology, applied in the field of imitation rattan materials, can solve the problems of not greatly improving the mechanical properties of the final product, increasing the wear degree of production equipment, reducing the melt index of materials, etc., to improve added value and good texture. , the effect of reducing the melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

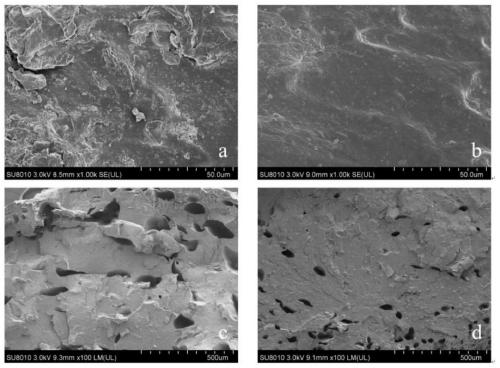

Image

Examples

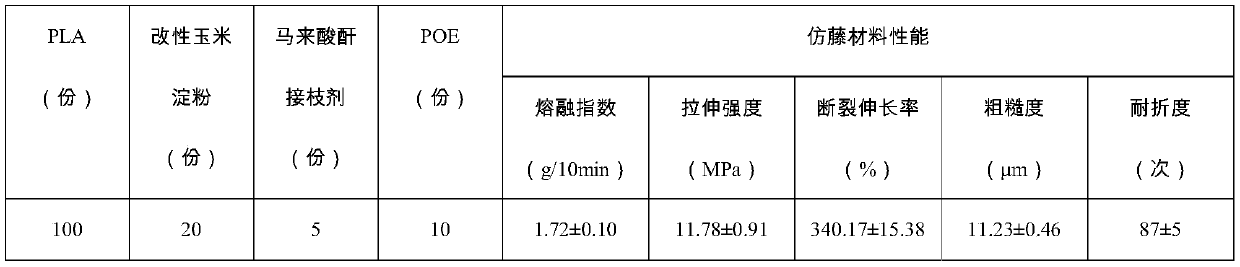

Embodiment 1

[0027] Embodiment 1 (modified starch different add-on)

[0028] Preparation of modified starch: Add corn starch into a high-speed mixer, then add silane coupling agent accounting for 10% of the starch mass, heat to 100°C, and maintain the temperature for 15 minutes to obtain modified starch.

[0029] Get different weight parts of modified starch, compound with 100 parts of thermoplastic PLA, 5 parts of maleic anhydride grafting agent and 10 parts of POE to prepare starch-containing biomass imitation rattan material, the preparation method is as follows:

[0030] (1) Mixing of raw materials: take modified starch or modified starch-coffee grounds mixed biomass according to the weight ratio, then add thermoplastics, mix and stir evenly;

[0031] (2) Granulation: the mixture obtained in step (1) is added into a maleic anhydride grafting agent, mixed uniformly and placed in a granulation device for granulation to obtain a modified plastic masterbatch;

[0032] (3) Extrusion moldin...

Embodiment 2

[0038] Embodiment 2 (different types of starch modifiers)

[0039] Using cornstarch and thermoplastics as raw materials, after modifying cornstarch with different modifiers (the addition amount is 10% of the weight of cornstarch), 40 parts of modified starch, 100 parts of PLA, 5 parts of Malay Acid anhydride grafting agent, 10 parts of POE are raw materials, adopt the preparation method of embodiment 1 to carry out the preparation of rattan-like material, and carry out the same pretreatment and follow-up rattan-like material preparation with the mode that does not add modifier to corn starch as Control group, the performance test result of the prepared product is shown in Table 2 below:

[0040] Table 2 Effects of different modifiers on the properties of imitation rattan materials

[0041]

[0042]

[0043]It can be seen from Table 2 that the aqueous solution of hydroxypropyl vitamin can make the starch biomass imitation rattan have a better melt index, which can reduce...

Embodiment 3

[0045] Embodiment 3 (selection of different thermoplastics)

[0046] With silane coupling agent as modifier, with the weight ratio of modified starch and thermoplastic 40:100, select different types of raw materials, adopt the preparation method of embodiment 1 to carry out the preparation of imitation rattan material, specific raw material selection type and The performance test results of rattan-like materials are shown in Table 3 and Table 4 below:

[0047] Table 3 Effects of different thermoplastics on the properties of rattan-like materials

[0048]

[0049]

[0050] It can be seen from Table 3 that the properties of PLA and LLDPE are similar, and LLDPE has more advantages in terms of folding endurance. PLA is a fully degradable material, so PLA is preferred.

[0051] Table 4 Effects of different types of starch on the properties of rattan-like materials

[0052]

[0053] It can be seen from Table 4 that different types of starch have a certain impact on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com