Wooden architecture templet preparation method and the wooden architecture templet prepared by the method

A wooden building and formwork technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of waste, heavy steel formwork, perishable wood, insects, etc., and achieve reliable quality and convenient construction Beautiful and unique effect on construction and building walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

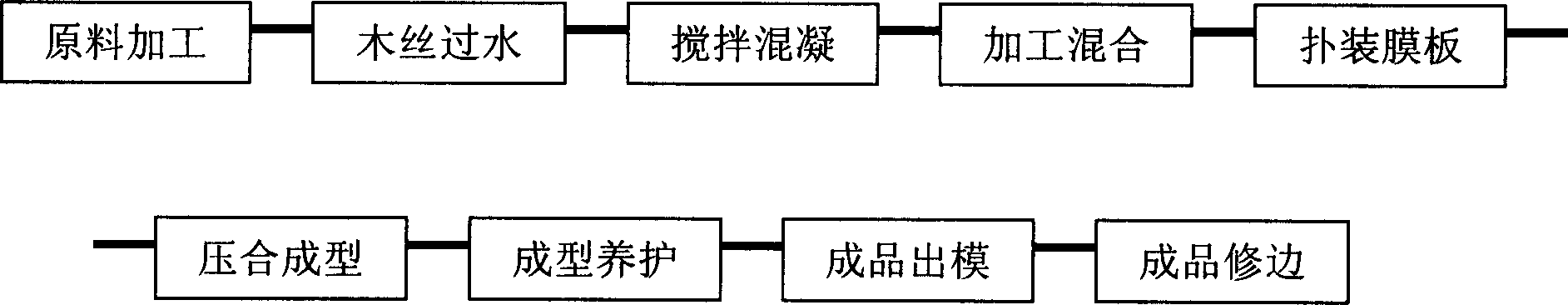

[0022] The raw material is processed first, and the wood is cut into shreds. The length of each wood shred is 5-250mm, and its section can be round or square. If it is round, the diameter of its cross-section is 1-8mm. The long side is 1-8mm, and the short side is 1-8mm; then take 0.5 tons of the above-mentioned raw material wood wool and put it into a soaking tank for soaking, and at the same time take 0.8 tons of portland cement and 0.15 tons of water. Carry out concrete mixing; then fully mix the soaked raw wood wool and the well-mixed concrete, and fill it in the formwork mold, and press the press machine with a pressure of 20KN for 1 day to make the wood wool and concrete It is fully compressed and formed; then the compression-molded mold and formwork are naturally cured. Natural curing can be dried at room temperature or steam cured. If steam cured and dried, the steam temperature can be 40°C; finally, dismantled Mold, that is: the finished product is released from the m...

Embodiment 3

[0026] The raw material is processed first, and the wood is cut into shreds. The length of each wood shred is 5-250mm, and its section can be round or square. If it is round, the diameter of its cross-section is 1-8mm. The long side is 1-8mm, and the short side is 1-8mm; then take 0.8 tons of the above-mentioned raw material wood wool, put it in a soaking tank for soaking, and at the same time take 1 ton of Portland cement and 0.5 tons of water , to carry out concrete mixing; then fully mix and mix the soaked raw wood wool and the well-mixed concrete, put it into the formwork mold, fill it, and then press it with a pressure of 5000KN for 6 days, so that The wood wool and concrete are fully compressed and formed; then, the compression-molded molds and templates are subjected to natural curing. The natural curing can be dried at room temperature or steam cured. If steam cured and dried, the steam temperature can be 60 ℃; Finally, the mold is removed, that is, the finished produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com