Processing method and equipment for softening hard water through electric flocculation

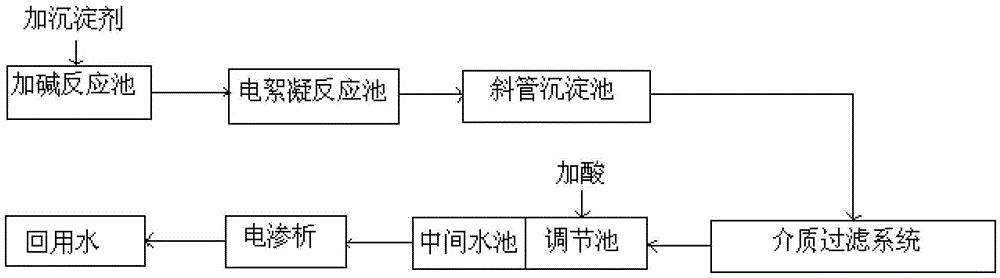

A treatment method and technology of treatment equipment, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. problem, to solve the low hardness removal rate, improve the hardness removal rate, and strengthen the removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

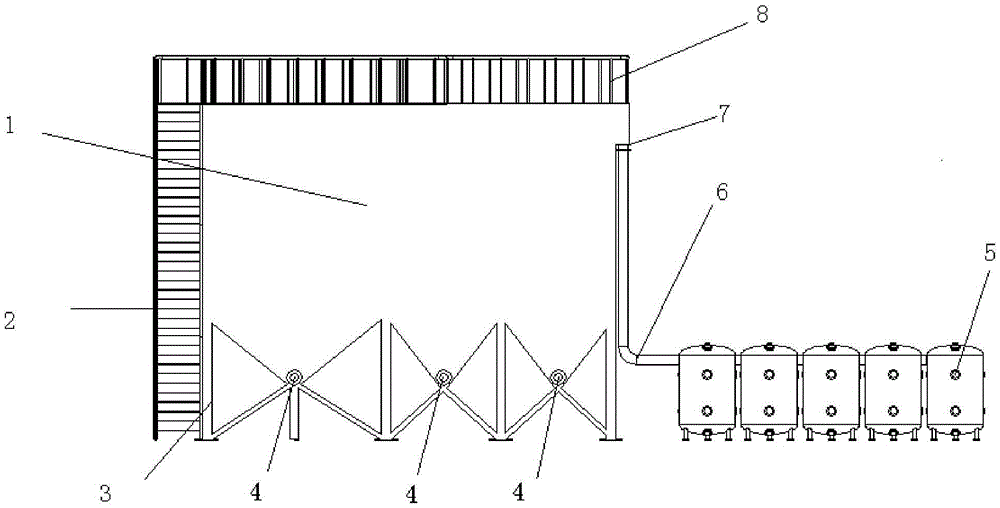

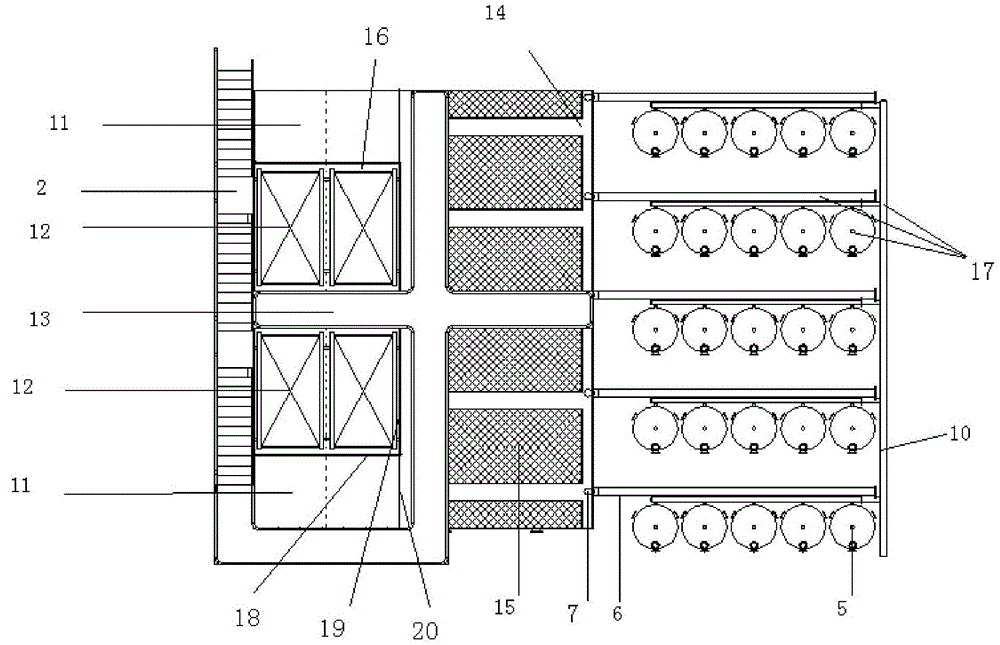

[0059] Adopt method of the present invention and equipment to hardness be 800ppm, the hard water that volume is 100L is processed, as Figure 2-Figure 4 As shown, the equipment of this embodiment: includes alkali addition reaction pool 11, electroflocculation reaction pool 16, inclined tube sedimentation tank 15 and medium filtration system 17, wherein there is a partition a18 between alkali addition reaction pool 11 and electroflocculation reaction pool 16 , there is a partition b19 between the electrocoagulation reaction tank 16 and the inclined tube sedimentation tank 15, a partition c20 is arranged between the alkali addition reaction tank 11 and the inclined tube sedimentation tank 16, the alkali addition reaction tank 11, the electroflocculation reaction tank 16 and the inclined tube The tube sedimentation tank 15 is a complete set; the electrocoagulation reaction tank 16 is equipped with an electrocoagulation module 12, and a water collection tank 14 is arranged above th...

Embodiment 2

[0067] Adopt the method and equipment of the present invention to be 1000ppm to hardness, the hard water that volume is 100L is processed, as Figure 2-Figure 4 As shown, the equipment of this embodiment: includes alkali addition reaction pool 11, electroflocculation reaction pool 16, inclined tube sedimentation tank 15 and medium filtration system 17, wherein there is a partition a18 between alkali addition reaction pool 11 and electroflocculation reaction pool 16 , there is a partition b19 between the electrocoagulation reaction tank 16 and the inclined tube sedimentation tank 15, a partition c20 is arranged between the alkali addition reaction tank 11 and the inclined tube sedimentation tank 16, the alkali addition reaction tank 11, the electroflocculation reaction tank 16 and the inclined tube The tube sedimentation tank 15 is a complete set; the electrocoagulation reaction tank 16 is equipped with an electrocoagulation module 12, and a water collection tank 14 is arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com