Novel cold rolled driving roller heat treatment process

A transmission roller and preheating technology, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of ineffective elimination of internal stress and the amount of ferromagnetic iron, so as to improve hardness, solve cracks, and reduce deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

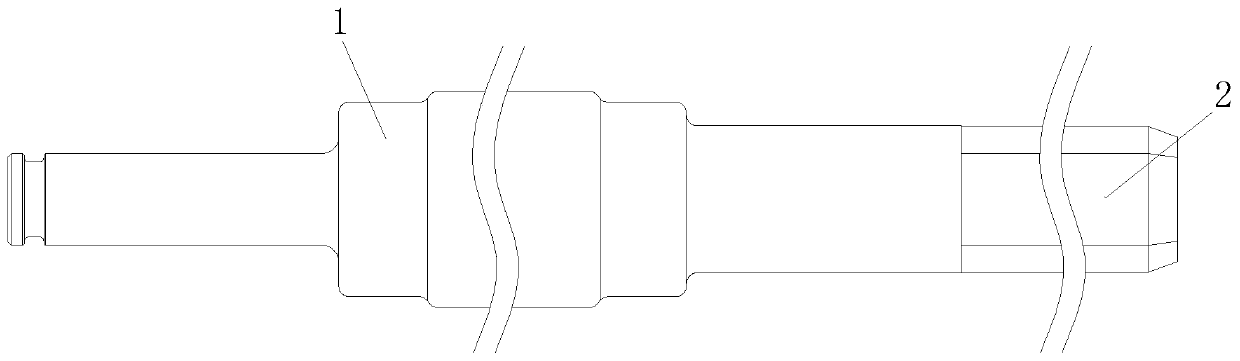

Image

Examples

Embodiment 1

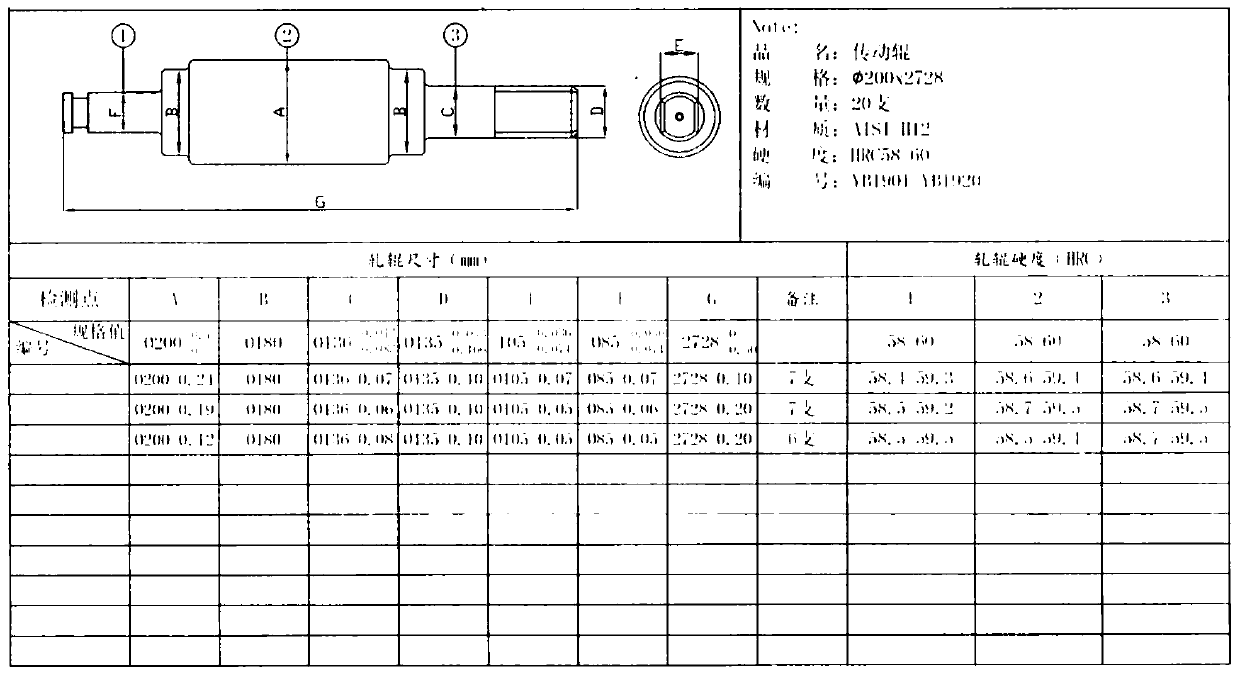

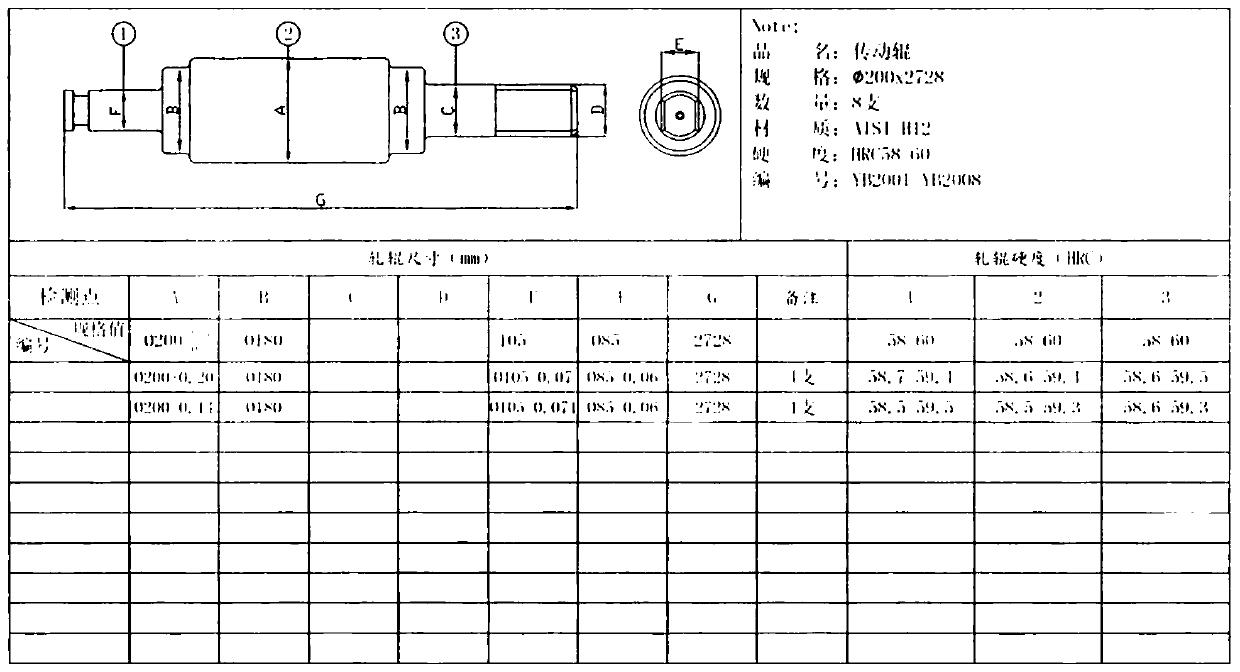

[0035] like Figure 2-3 As shown, take the heat treatment processing of φ200*2728 cold-rolled drive roll as an example:

[0036] A novel heat treatment process for a cold-rolled drive roller, comprising the following heat treatment steps:

[0037] S1. The cold rolling drive roll is heat treated by the sub-preheating method, preheating in the heating equipment, and successively preheating at 400 °C → 600 °C preheating → 800 °C preheating, 400 °C preheating time is 9 hours, 600 °C preheating The preheating time at ℃ is 6 hours, and the preheating time at 800℃ is 3 hours;

[0038] S2. After the cold rolling drive roller is preheated, it is heated at 995-1140°C by heating equipment, and the heating time is 100min;

[0039] S3. After the cold-rolled drive roller is heated at high temperature, it is air-cooled to within 70-90 °C, and then placed in a quenching equipment for constant temperature quenching treatment. The constant temperature quenching temperature range is 150-180 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com