Hot-recycling asphalt mixture containing non-traditional oil and preparation method of hot-recycling asphalt mixture

A technology for non-traditional grease and asphalt mixture, applied in the field of non-traditional grease thermally regenerated asphalt mixture and its preparation, can solve the problem of unsatisfactory high and low temperature performance of mineral oil regenerated asphalt, expensive ARA regenerant, poor regeneration effect of mixture, etc. problems, achieving significant socio-economic and environmental benefits, ease of implementation, and reduced application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Non-traditional grease thermally recycled AC-25 asphalt mixture, applied to the lower layer, is prepared from waste asphalt mixture, new aggregate, new asphalt and non-traditional grease regenerant (by compounding, heating, and mixing processes). Waste and old asphalt mixture accounts for 50% of the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator, and new asphalt accounts for the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator 1.5% of non-traditional grease rejuvenators accounted for 3% of the bitumen mass in waste asphalt mixture.

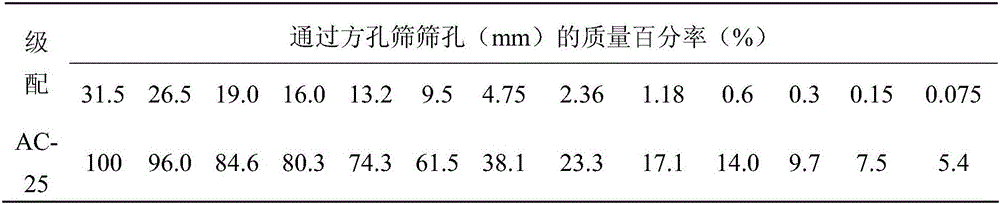

[0036] According to the requirements of "Code for Design of Highway Asphalt Pavement" (JTGD50-2006), waste asphalt mixture, coarse aggregate, fine aggregate and filler in new aggregate are graded and synthesized. The synthetic gradation is shown in Table 1.

[0037] Table 1 AC-25 screening and synthesis gradation

[0038]...

Embodiment 2

[0054] Non-traditional oil heat recycled AC-20 asphalt mixture, applied to the middle surface layer, prepared from waste asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator (by compounding, heating, mixing process) . Waste and old asphalt mixture accounts for 40% of the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator, and new asphalt accounts for the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator 1%, non-traditional grease rejuvenators accounted for 2% of the bitumen mass in waste asphalt mixture.

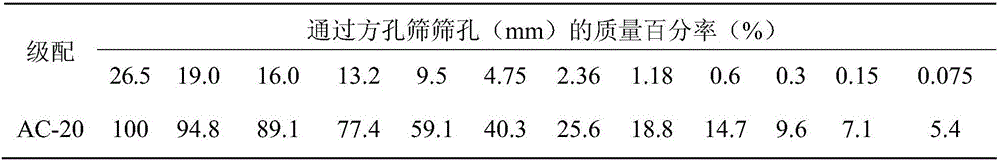

[0055] According to the requirements of "Code for Design of Highway Asphalt Pavement" (JTGD50-2006), the waste asphalt mixture, the coarse and fine aggregates and fillers in the new aggregate are graded and synthesized. The synthetic gradation is shown in Table 2.

[0056] Table 2 AC-20 screening and synthesis gradation

[0057]

...

Embodiment 3

[0073] Non-traditional grease heat recycled AC-16 asphalt mixture, applied to the upper layer, is prepared from waste asphalt mixture, new aggregate, new asphalt and non-traditional grease regenerant (by compounding, heating, and mixing processes). Waste and old asphalt mixture accounts for 30% of the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator, and new asphalt accounts for the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator 2%, non-traditional grease rejuvenators accounted for 1% of the bitumen mass in waste asphalt mixture.

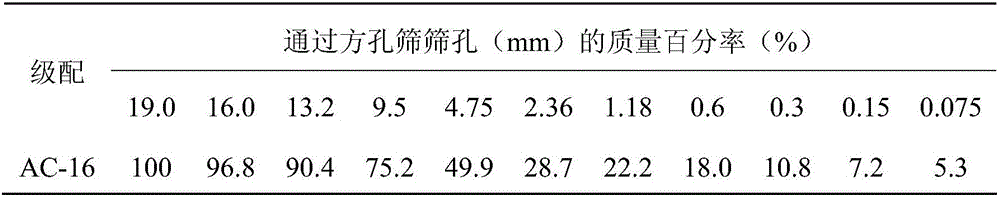

[0074] According to the requirements of "Code for Design of Highway Asphalt Pavement" (JTGD50-2006), the waste asphalt mixture, the coarse and fine aggregates and fillers in the new aggregate are graded and synthesized. The synthetic gradation is shown in Table 3.

[0075] Table 3 AC-16 screening and synthesis gradation

[0076] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com