Layered thermal milling equipment, hot air microwave composite in-situ thermal regeneration complete set and layered construction method

A technology of hot air heating and milling, which is applied in road repair, road, construction, etc., and can solve problems such as difficulty in adding new materials, large leakage of smoke and dust, and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

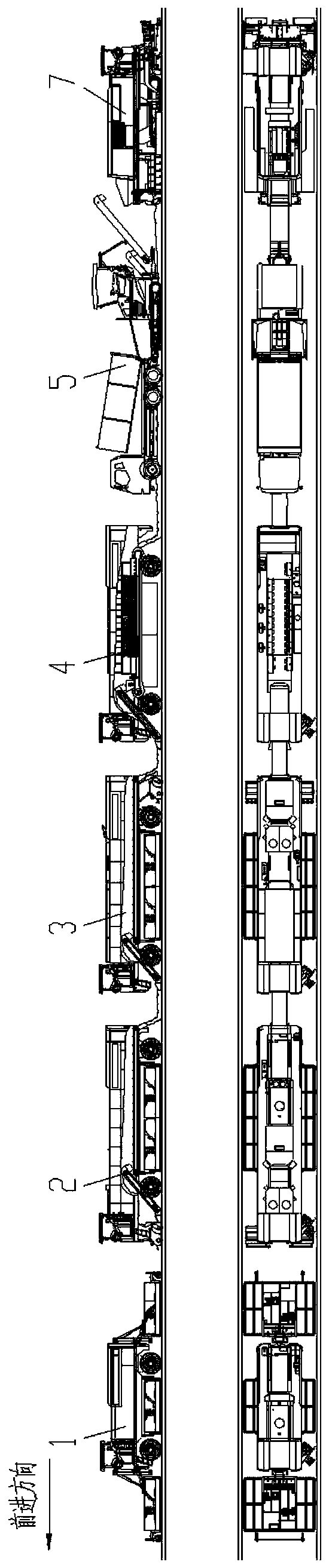

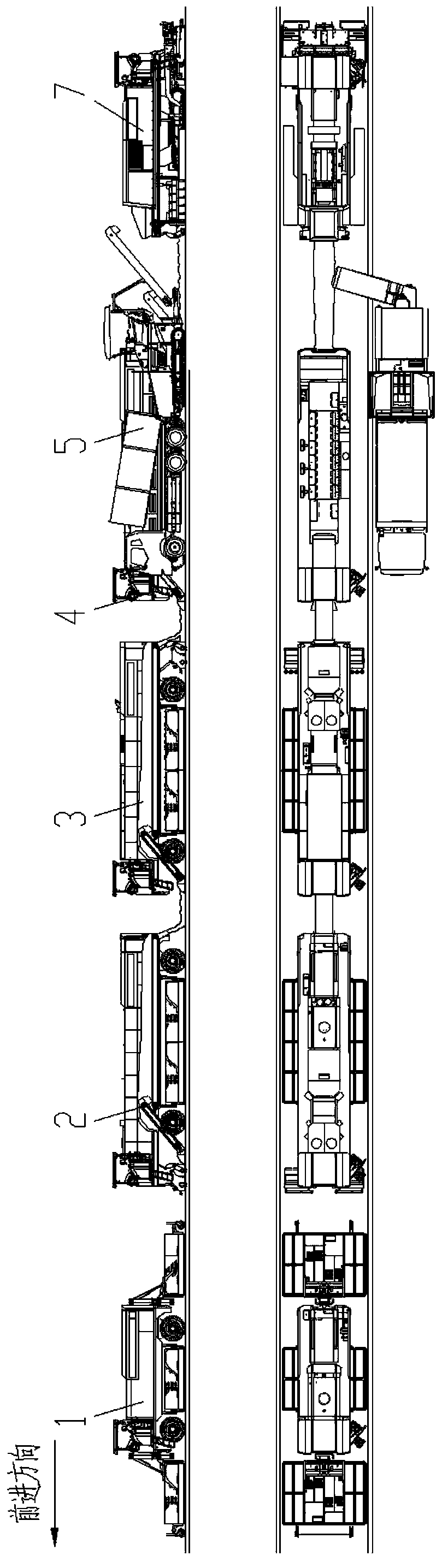

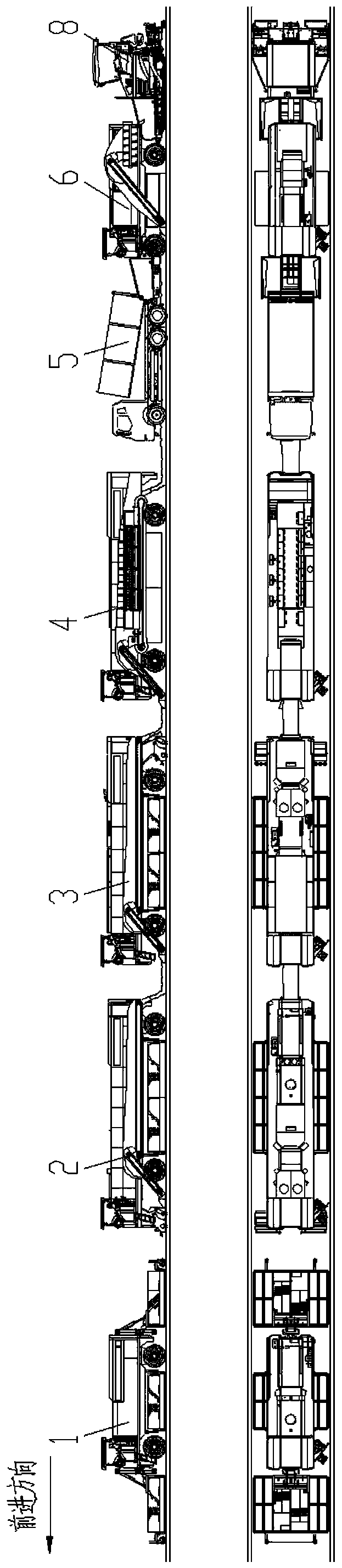

[0081] The embodiment of the present invention provides a layered thermal milling equipment, including: a hot air heater 1, a front milling heater 2, and a rear milling heater 3 are arranged in sequence;

[0082] In order to overcome the environmental pollution and road performance degradation caused by traditional oil / gas open fire heating, gas infrared heating or extensive high-power diesel hot air heating, which is easy to scorch the asphalt pavement, and effectively avoid the high temperature and hot smoke around the construction that may easily cause damage to green belts and trees For the problem of scorching, this embodiment adopts a new modular variable power hot air heating technology, through the modularization of several heaters, the temperature of the hot air inlet and return air is precisely controlled. The maximum temperature of the asphalt pavement surface does not exceed 180 ° C, and the inside of the road is 20mm ~ 30mm The temperature at the place is not lower...

Embodiment 2

[0088] Based on the same inventive concept as that of Embodiment 1, the embodiment of the present invention provides a hot air microwave composite hot-in-place regeneration unit, which can not only realize layered thermal milling, but also overcome the infrared heating or hot-air heating used by hot-in-place regeneration units on the market. The temperature should not be precisely controlled, which will easily cause secondary aging of recycled materials and affect the quality of recycled materials. The microwave tunnel heating machine adopts tunnel-type microwave heating technology, and uses 2.45GHz frequency microwave to carry out secondary heating of recycled materials after layered milling. , to achieve non-destructive, uniform and efficient heating of the asphalt pavement, to ensure that the temperature of the asphalt material in each link reaches the standard, and to restore the performance of the asphalt road, smoke-free and environmentally friendly.

[0089] The hot air ...

Embodiment 3

[0102] Based on the same inventive concept as in Example 2, the embodiment of the present invention provides a regeneration method with addition of materials, see Figure 1 to Figure 3 As shown, the described regeneration process of adding materials and mixing comprises the following steps:

[0103] Step S11, use several hot air heaters 1 to heat the old asphalt pavement, the heating depth of the old asphalt pavement is 20mm-30mm, the maximum temperature of the surface layer of the old asphalt pavement does not exceed 180°C, and the temperature at 20mm-30mm inside the road surface is not lower than 110°C ℃;

[0104] Step S12, use the front milling heating machine 2 to accurately spray regenerant and hot asphalt on the road surface before hot milling, and then the front milling device 2-1 performs hot milling on the old asphalt road surface of 20 mm to 30 mm, and the milling process introduces The first flue gas recovery treatment device 2-7 performs flue gas recovery treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com