Recycled asphalt mixture and preparation method thereof

A technology for asphalt mixture and regenerated asphalt, applied in the field of asphalt mixture, can solve the problems affecting the performance of asphalt mixture, secondary aging of asphalt, etc., to improve compressive strength and fatigue resistance, restore road performance, and achieve good resistance The effect of compressive strength and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The waste asphalt mixture is prepared by the following method: take the waste material produced during the repair process of the road asphalt layer of the expressway, add it to the crusher for crushing, and sieve to obtain the waste material with a particle size of less than 5mm, 5-15mm waste material, 15 -25mm waste material; mix 0-5mm waste material, 5-15mm waste material and 15-25mm waste material according to the mass ratio of 3:6:2 to get the product.

[0036]The new aggregate is basalt from Hubei Basalt Rock Material Co., Ltd., with a particle size of 5-15mm.

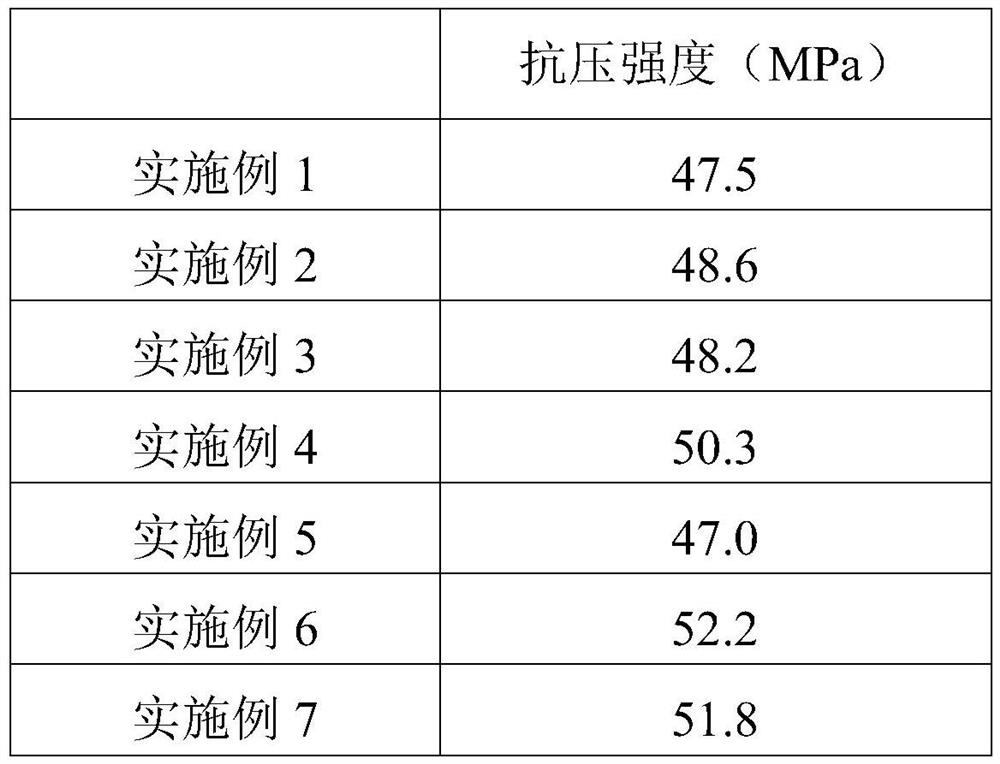

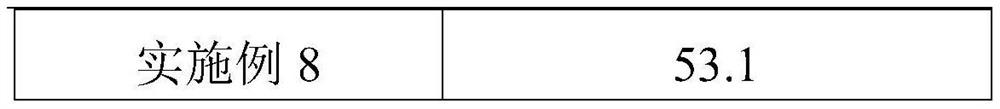

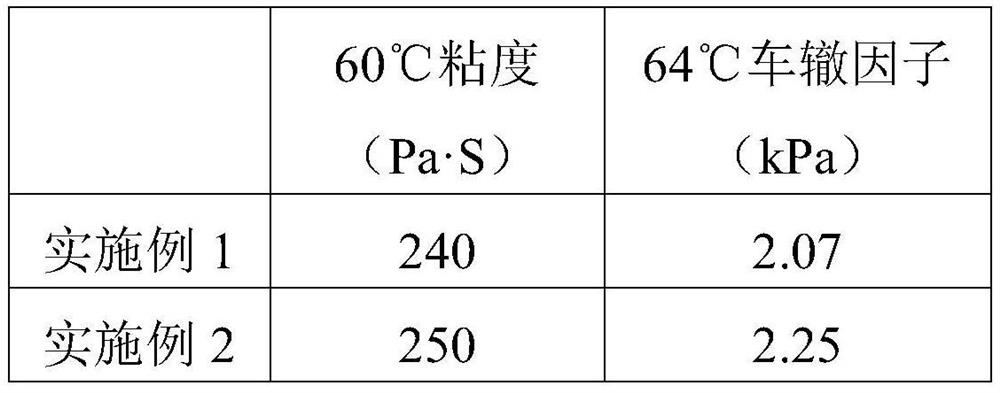

Embodiment 1

[0038] A preparation method for recycled asphalt mixture, comprising the following steps:

[0039] S1. Take 5 parts by weight of asphalt, 0.6 parts by weight of asphalt regenerant, 18 parts by weight of waste asphalt mixture and 57 parts by weight of new aggregate, and set aside;

[0040] S2. Put the waste asphalt mixture and the new aggregate into an oven for heat preservation at 150°C for 3 hours;

[0041] S3. Add asphalt and asphalt rejuvenator to the mixing tank, stir at 140°C for 10 minutes, and the stirring rate is 200 rpm; then add the waste asphalt mixture treated with heat preservation in S2 and new aggregate and continue stirring for 5 minutes to obtain a recycled asphalt mixture.

[0042] The asphalt regenerant is prepared by the following method:

[0043] (1) Take each raw material by weight: 10 parts of rapeseed oil, 60 parts of palm oil, 10 parts of asphalt, 18 parts of plasticizer, 5 parts of surfactant, 2 parts of antioxidant;

[0044] (2) Mix rapeseed oil an...

Embodiment 2

[0050] A preparation method for recycled asphalt mixture, comprising the following steps:

[0051] S1. Take 5 parts by weight of asphalt, 0.6 parts by weight of asphalt regenerant, 18 parts by weight of waste asphalt mixture and 57 parts by weight of new aggregate, and set aside;

[0052] S2. Put the waste asphalt mixture and the new aggregate into an oven for heat preservation at 150°C for 3 hours;

[0053] S3. Add asphalt and asphalt rejuvenator to the mixing tank, stir at 140°C for 10 minutes, and the stirring rate is 200 rpm; then add the waste asphalt mixture treated with heat preservation in S2 and new aggregate and continue stirring for 5 minutes to obtain a recycled asphalt mixture.

[0054] The asphalt regenerant is prepared by the following method:

[0055] (1) Take each raw material by weight: 10 parts of modified rapeseed oil, 60 parts of palm oil, 10 parts of asphalt, 18 parts of plasticizer, 5 parts of surfactant, 2 parts of antioxidant;

[0056] (2) Heat modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com