A kind of asphalt regenerant and its preparation method and application

A kind of technology of asphalt rejuvenator and plant asphalt, which is applied in the direction of climate change adaptation, building components, building insulation materials, etc. It can solve the problems of small dosage and inability to be used in large quantities, so as to enhance adhesion, restore and improve road performance , good wetting and spreading ability and the effect of ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

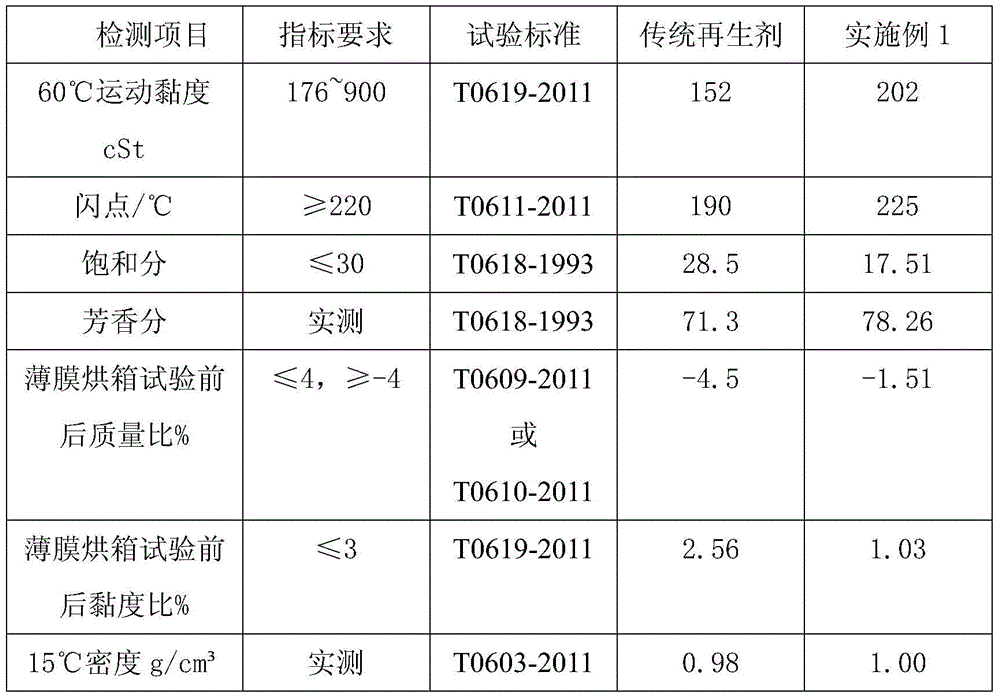

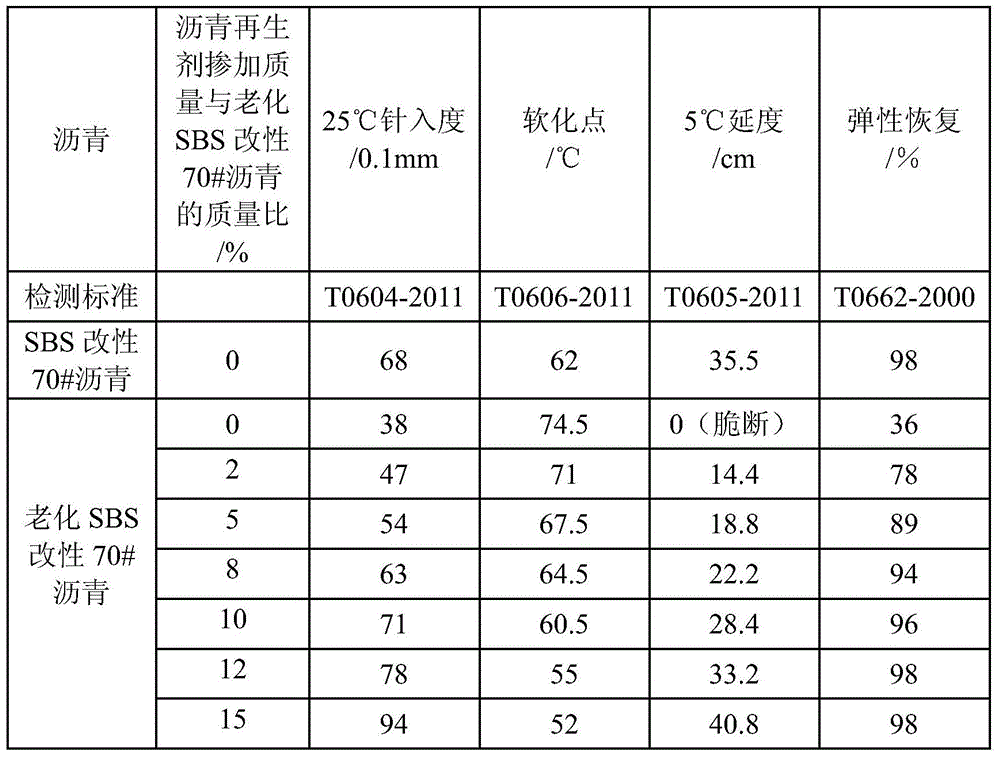

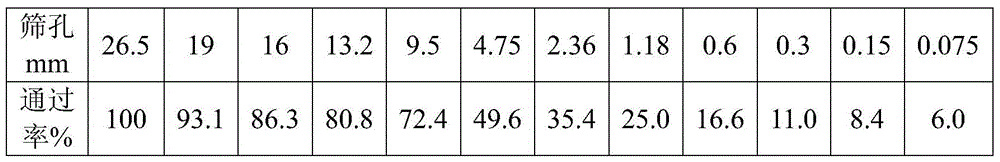

Embodiment 1

[0031] A kind of asphalt regeneration agent, by mass percentage, is made up of following raw materials:

[0032] Vegetable asphalt, accounting for 70% of the total mass of asphalt regenerant;

[0033] The interface strengthening modifier adopts epoxy silicone resin, which accounts for 4% of the total mass of the asphalt agent regeneration agent, and the epoxy group content in the interface strengthening modifier is 10wt%;

[0034] The plasticizer is carboxymethyl cellulose, accounting for 25% of the total mass of asphalt regenerant;

[0035] The penetrant uses n-octane, accounting for 0.5% of the total mass of the asphalt regenerant;

[0036] The anti-aging agent adopts butylated hydroxytoluene (BHT), which accounts for 0.5% of the total mass of the asphalt regenerant;

[0037] According to the above ratio, taking the preparation of 100kg asphalt rejuvenator as an example, the preparation process of asphalt rejuvenator is as follows:

[0038] Heat 75kg of plant asphalt to 1...

Embodiment 2

[0053] A kind of asphalt regeneration agent, by mass percentage, is made up of following raw materials:

[0054] Vegetable asphalt, accounting for 80% of the total mass of asphalt regenerant;

[0055] The reinforcement modifier adopts epoxy resin, which accounts for 3% of the total mass of the asphalt regenerant, and the epoxy group content in the interface reinforcement modifier is 40wt%.

[0056] The plasticizer is hydroxyethyl cellulose, accounting for 15% of the total mass of the asphalt regenerant;

[0057] The penetrating agent adopts trichlorethylene, accounting for 1% of the total mass of the asphalt regenerant;

[0058] The anti-aging agent adopts 2-hydroxy-4-methoxy-5-sulfobenzophenone (UV-284), accounting for 1% of the total mass of asphalt regenerant;

[0059] According to the above ratio, taking the preparation of 100kg asphalt rejuvenator as an example, the preparation process of asphalt rejuvenator is as follows

[0060] Take 80kg of plant asphalt and heat it...

Embodiment 3

[0075] A kind of asphalt regeneration agent, by mass percentage, is made up of following raw materials:

[0076] Vegetable asphalt, accounting for 65% of the total mass of asphalt regenerant;

[0077] The reinforcement modifier adopts epoxy aliphatic polyethylene polyamine, which accounts for 3% of the total mass of the asphalt regenerant, and the epoxy group content in the interface reinforcement modifier is 30wt%

[0078] Modified petroleum resin is used as plasticizer, accounting for 30% of the total mass of asphalt regeneration agent;

[0079] Chloroform is used as penetrating agent, accounting for 1% of the total mass of asphalt regenerant;

[0080] The anti-aging agent adopts butylated hydroxytoluene (BHT), which accounts for 1% of the total mass of the asphalt regenerant;

[0081] According to the above ratio, taking the preparation of 100kg asphalt rejuvenator as an example, the preparation process of asphalt rejuvenator is as follows:

[0082] Take 65kg of plant as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com