A kind of non-traditional grease heat recycled asphalt mixture and preparation method thereof

A technology for non-traditional grease and asphalt mixture, applied in the field of non-traditional grease thermally regenerated asphalt mixture and its preparation, can solve the problem of unsatisfactory high and low temperature performance of mineral oil regenerated asphalt, expensive ARA regenerant, poor regeneration effect of mixture, etc. problems, achieving significant socio-economic and environmental benefits, ease of implementation, and reduced application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Non-traditional grease thermally recycled AC-25 asphalt mixture, applied to the lower layer, is prepared from waste asphalt mixture, new aggregate, new asphalt and non-traditional grease regenerant (by compounding, heating, and mixing processes). Waste and old asphalt mixture accounts for 50% of the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator, and new asphalt accounts for the total mass of waste and old asphalt mixture, new aggregate, new asphalt and non-traditional oil rejuvenator 1.5% of non-traditional grease rejuvenators accounted for 3% of the bitumen mass in waste asphalt mixture.

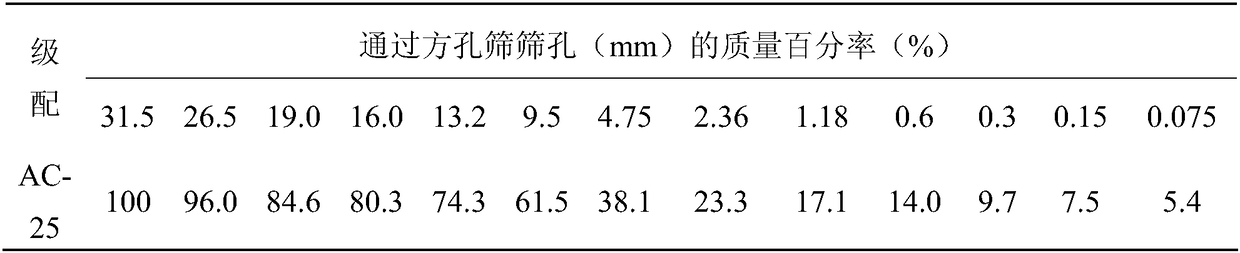

[0036] According to the requirements of "Code for Design of Highway Asphalt Pavement" (JTG D50-2006), waste asphalt mixture, coarse aggregate, fine aggregate and filler in new aggregate are graded and synthesized. The synthetic gradation is shown in Table 1.

[0037] Table 1 Sieving and synthetic gradation of AC-25

[003...

Embodiment 2

[0054] 非传统油脂热再生AC-20沥青混合料,应用于中面层,由废旧沥青混合料、新集料、新沥青和非传统油脂再生剂制备而成(通过复掺、加热、拌合工艺)。废旧沥青混合料占废旧沥青混合料、新集料、新沥青和非传统油脂再生剂总质量的40%,新沥青占废旧沥青混合料、新集料、新沥青和非传统油脂再生剂总质量的1%,非传统油脂再生剂占废旧沥青混合料中沥青质量的2%。

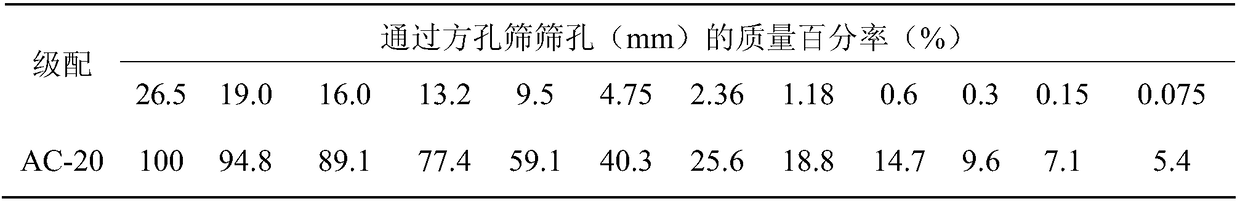

[0055] 根据《公路沥青路面设计规范》(JTG D50-2006)的要求,对废旧沥青混合料、新集料中粗、细集料及填料进行级配合成,其合成级配见表2。

[0056] 表2 AC-20筛分及合成级配

[0057]

[0058] 所述废旧沥青混合料是路面下面层翻修过程产生的废料经破碎、筛分工艺处理而得到。

[0059] 所述新集料包括粗集料、细集料和石灰岩矿粉(填料)。

[0060] 所述新沥青为废旧沥青同标号同产源的AH-50沥青,即AH-50重交通道路石油沥青[可采用中海沥青(泰州)有限公司供应的]。

[0061] 所述非传统油脂再生剂是由含55%低粘度“油”(不饱和脂肪酸甘油酯)与45%高粘度“脂”(饱和脂肪酸甘油酯)的废弃油脂经过滤、脱水、除臭工艺处理而得到。

[0062] 上述一种非传统油脂热再生沥青混合料的制备方法,它包括如下步骤:

[0063] 1)将经过破碎、筛分处理的废旧沥青混合料、新集料分别置于105℃±5℃(即100-110℃)的烘箱中烘干至恒重(一般不少于4~6h);

[0064] 并对废旧沥青混合料取样分析出:废旧沥青混合料中沥青的质量百分含量;

[0065] 2)按废旧沥青混合料、新集料、新沥青占废旧沥青混合料、新集料、新沥青和非传统油脂再生剂总质量的百分数为:废旧沥青混合料40%、新沥青1.0%,非传统油脂再生剂占废旧沥青混合料中沥青质量的2.0%,选取废旧沥青混合料、新沥青和非传统油脂再生剂;

[0066] 所述新集料包括粗集料、细集料和填料;

[0067] 并按混合料设计级配称量新集料中粗集料、细集料的质量,并初步混合;烘干后的填料单独称量存放(填料按混合料设计级配称量);

[0068] 3)将初步混合的废旧沥青混合料和新集料中的粗集料、细集料放入烘箱内在175℃下保温至少4h;

[...

Embodiment 3

[0073] 非传统油脂热再生AC-16沥青混合料,应用于上面层,由废旧沥青混合料、新集料、新沥青和非传统油脂再生剂制备而成(通过复掺、加热、拌合工艺)。废旧沥青混合料占废旧沥青混合料、新集料、新沥青和非传统油脂再生剂总质量的30%,新沥青占废旧沥青混合料、新集料、新沥青和非传统油脂再生剂总质量的2%,非传统油脂再生剂占废旧沥青混合料中沥青质量的1%。

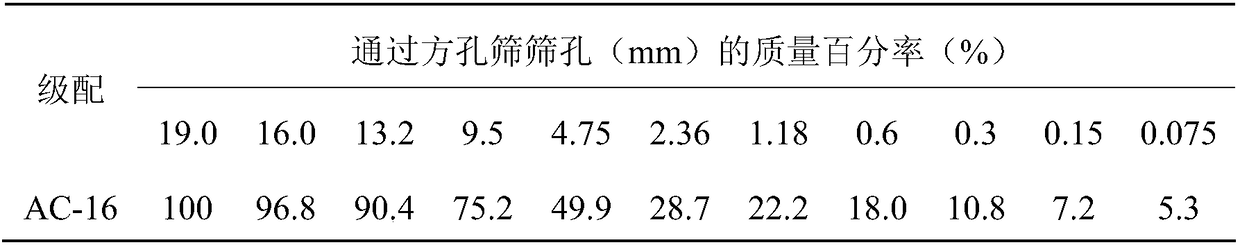

[0074] 根据《公路沥青路面设计规范》(JTG D50-2006)的要求,对废旧沥青混合料、新集料中粗、细集料及填料进行级配合成,其合成级配见表3。

[0075] 表3 AC-16筛分及合成级配

[0076]

[0077] 所述废旧沥青混合料是路面下面层翻修过程产生的废料经破碎、筛分工艺处理而得到。

[0078] 所述新集料包括粗集料、细集料和石灰岩矿粉(填料)。

[0079] 所述新沥青为废旧沥青同标号同产源的AH-50沥青,即AH-50重交通道路石油沥青[可采用中海沥青(泰州)有限公司供应的]。

[0080] 所述非传统油脂再生剂是由含55%低粘度“油”(不饱和脂肪酸甘油酯)与45%高粘度“脂”(饱和脂肪酸甘油酯)的废弃油脂经过滤、脱水、除臭工艺处理而得到。

[0081] 上述一种非传统油脂热再生沥青混合料的制备方法,它包括如下步骤:

[0082] 1)将经过破碎、筛分处理的废旧沥青混合料、新集料分别置于105℃±5℃的烘箱中烘干至恒重(一般不少于4~6h);

[0083] 并对废旧沥青混合料取样分析出:废旧沥青混合料中沥青的质量百分含量;

[0084] 2)按废旧沥青混合料、新集料、新沥青占废旧沥青混合料、新集料、新沥青和非传统油脂再生剂总质量的百分数为:废旧沥青混合料30%、新沥青2.0%,非传统油脂再生剂占废旧沥青混合料中沥青质量的1.0%,选取废旧沥青混合料、新沥青和非传统油脂再生剂;

[0085] 所述新集料包括粗集料、细集料和填料;

[0086] 并按混合料设计级配称量新集料中粗集料、细集料的质量,并初步混合;烘干后的填料单独称量存放(填料按混合料设计级配称量);

[0087] 3)将初步混合的废旧沥青混合料和新集料中的粗集料、细集料放入烘箱内在175℃下保温至少4h;

[0088] 4)将非传...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com