Treatment method of paper mulberry bark for papermaking

A processing method and mulberry bark technology, applied in the field of papermaking, can solve the problems of fiber strength, reduce pulping yield, damage fiber raw materials, etc., and achieve the effects of ensuring yield, improving pulp yield, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

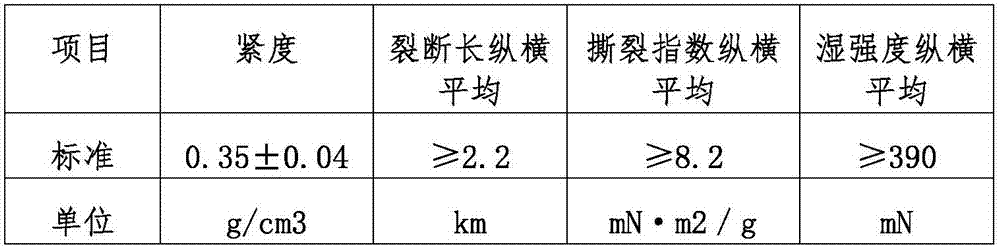

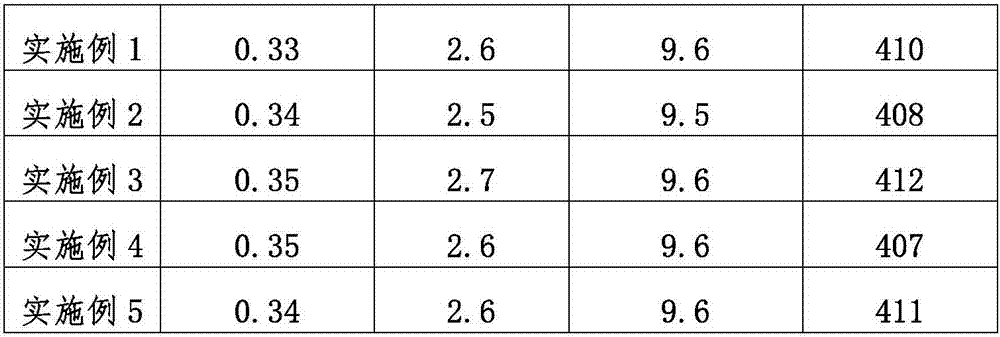

Examples

Embodiment 1

[0027] A processing method for papermaking bark, comprising the following steps:

[0028] (1) Drying: spread the bark peeled off from the tree bark on the ground after two o'clock every day for drying, turn it over every 2 hours, and dry it until the bark is dry The water content is 5%;

[0029] (2) One-time soaking: Soak the sun-dried bark with water. During the soaking process, add water in time so that the water surface exceeds the interface of the bark by 5-7cm. After soaking for 2-5 days, remove the bark and drain. Dry, soak with lime water with a concentration of 30%, the amount of lime water added should not exceed the bark, soak for 15 to 20 days, and then remove;

[0030] (3) One-time steaming: the soaked bark is evenly stacked in a steamer with a temperature of 90°C, and steamed for 8 hours;

[0031] (4) Secondary bubble skin: Take out the steamed bark, beat the bark with a mechanical board for 30-50 minutes, then soak the bark in water for 20 hours, remove and dra...

Embodiment 2

[0036] A processing method for papermaking bark, comprising the following steps:

[0037] (1) Drying: spread the bark peeled off from the tree bark on the ground after two o'clock every day for drying, turn it over every 2 hours, and dry it until the bark is dry The water content is 6%;

[0038] (2) One-time soaking: Soak the sun-dried bark with water. During the soaking process, add water in time so that the water surface exceeds the interface of the bark by 5-7cm. After soaking for 2-5 days, remove the bark and drain. Dry, soak with lime water with a concentration of 40%. The amount of lime water added should not exceed the bark. After soaking for 20 days, remove it;

[0039] (3) One-time steaming: the soaked bark is evenly stacked in a steamer with a temperature of 110°C, and steamed for 12 hours;

[0040] (4) Secondary bubble skin: take out the steamed bark, pat the bark with a mechanical board for 50 minutes, then soak the bark in water for 24 hours, remove and drain, a...

Embodiment 3

[0045] A processing method for papermaking bark, comprising the following steps:

[0046] (1) Drying: spread the bark peeled off from the tree bark on the ground after two o'clock every day for drying, turn it over every 2 hours, and dry it until the bark is dry The water content is 5.5%;

[0047] (2) One-time soaking: Soak the sun-dried bark with water. During the soaking process, add water in time so that the water surface exceeds the interface of the bark by 5-7cm. After soaking for 2-5 days, remove the bark and drain. Dry, soak with lime water with a concentration of 35%, the amount of lime water added should not exceed the bark, soak for 15 to 20 days, and then remove;

[0048] (3) One-time steaming: stack the soaked bark flatly in a steamer with a temperature of 100°C, and steam for 8 to 12 hours;

[0049] (4) Secondary bubble skin: take out the steamed bark, beat the bark with a mechanical board for 40 minutes, then soak the bark in water for 22 hours, remove and drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com