Cleaning agent applicable to descaling of landfill leachate evaporator and preparation method and application thereof

A landfill leachate and evaporator technology, which can be applied in chemical instruments and methods, preparation of detergent mixture compositions, detergent compounding agents, etc. problem, to achieve the effect of fast scaling, high temperature, and difficult to dissolve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

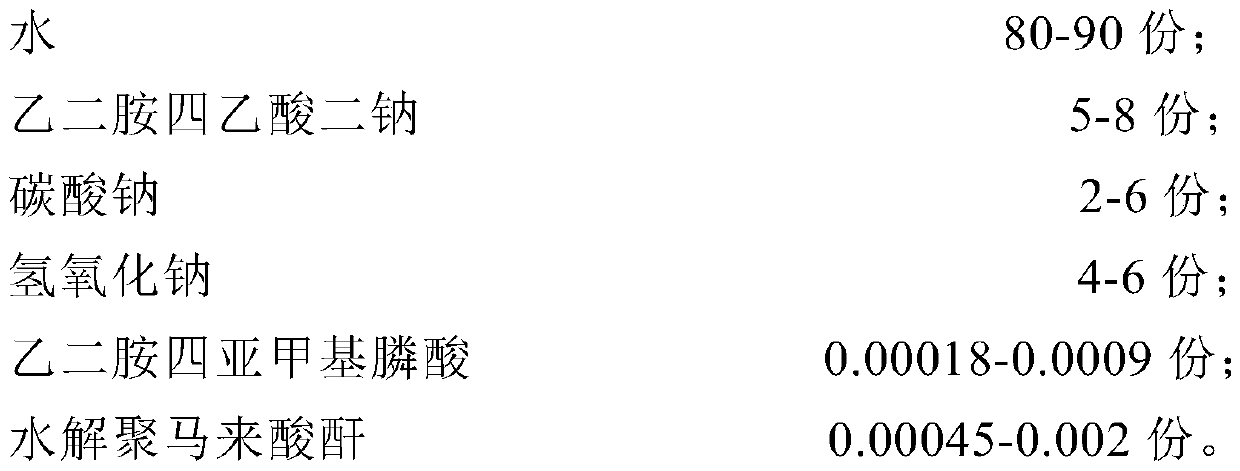

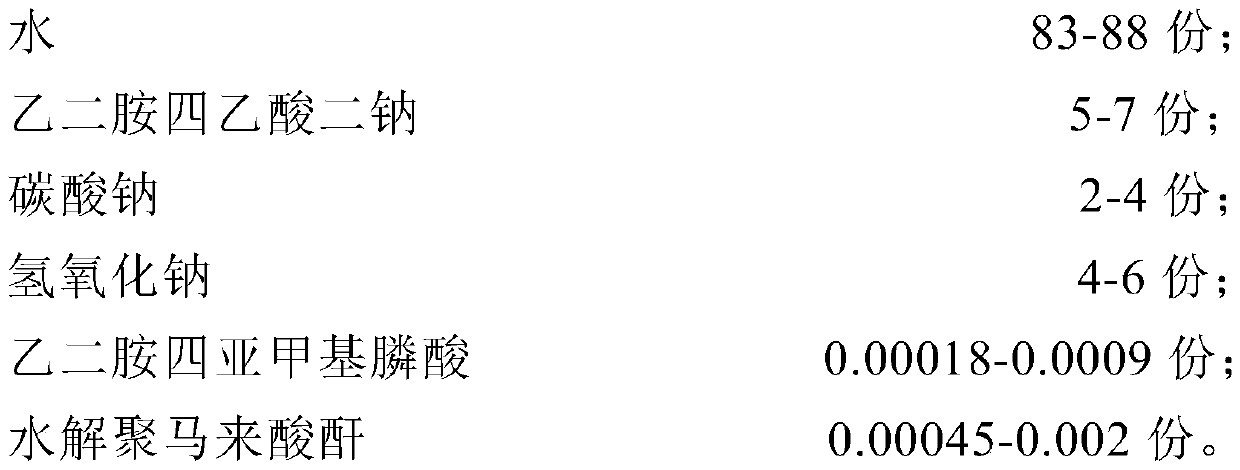

[0023] This embodiment 1-6 discloses 6 kinds of cleaning agents suitable for landfill leachate evaporators, and the contained components and total ratio are shown in Table 1.

[0024] The preparation method of the cleaning agent applicable to the landfill leachate evaporator is as follows: according to the above weight ratio, medicaments such as edetate disodium, sodium carbonate, sodium hydroxide, EDTMPS and HPMA are added to the water and stirred, and the control The rotation speed of the agitator is 200 rev / min, and the cleaning agent suitable for the landfill leachate evaporator is obtained by continuous stirring for 0.2 hours.

[0025] The weight ratio of component in the embodiment of table 1

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com