Patents

Literature

34results about How to "Easy to dissolve and disperse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clothes softener

Owner:SHANGHAI SOAP FACTORY

Treatment process of high-slag-content and water-containing sump oil

ActiveCN105419856AHigh recovery rateImprove dehydration rateDewatering/demulsification with chemical meansCavitationSlag

The invention relates to a treatment process of high-slag-content and water-containing sump oil and relates to the technical field of separation and treatment of slag-containing and water-containing sump oil. Firstly, the sump oil is washed with alkali liquor, emulsification systems of a W / O type and an O / W / O type in the sump oil are subjected to phase inversion to form emulsion of an O / W type, the viscosity of the high-slag-content and water-containing sump oil and the interfacial tension of the emulsion systems can be effectively reduced due to formation of the emulsion of the O / W type, and therefore mass transfer of a subsequent demulsifying agent is facilitated, and the demulsifying effect of the subsequent demulsifying agent fully acts. Then, sulfuric acid is added and made to react with sodium naphthenate, sodium naphthenate is reduced into naphthenic acid without the emulsifying effect, and therefore the emulsifying effect of sodium naphthenate is eliminated. Next, a demulsifying agent of a compound type and a flocculating agent are sequentially added, and further flocculating setting separation happens to part of dross remaining in an oil layer. Finally, the sump oil is treated through the acoustic cavitation effect of ultrasonic waves, the mechanical vibration effect and the heat treatment effect, water and slag are further removed, and crude oil is recycled.

Owner:YANGZHOU UNIV

Three-proofing coating for flexible printed circuit board

The invention relates to the technical field of printed circuit board protection and in particular relates to a three-proofing coating for a flexible printed circuit board. According to the three-proofing coating, the advantages of organic silicon resin and acrylic resin are integrated in formula, a low-toxicity efficient solvent is adopted for promoting dissolution and dispersion of the resin in water, a good curing effect is achieved, and ocimene has an effect of assisting in film formation and endows the coating with pleasant aroma; mixed resin is ultrasonically processed in the solvent at first technologically, so that the mixed resin easily reacts with other materials and is easily compatible with the materials, and the subsequent curing speed is increased; the prepared coating is a waterborne coating, is environmental friendly and has good waterproof moisture-resistant effects, and a cured paint film is good in hardness and toughness, can completely fit the flexible circuit board and is not easily cracked in vibration and bending processes of the flexible circuit board, so that three-proofing effects are further enhanced and the occurrence probability of circuit board faults caused by environmental factors is reduced.

Owner:乐凯特科技铜陵有限公司

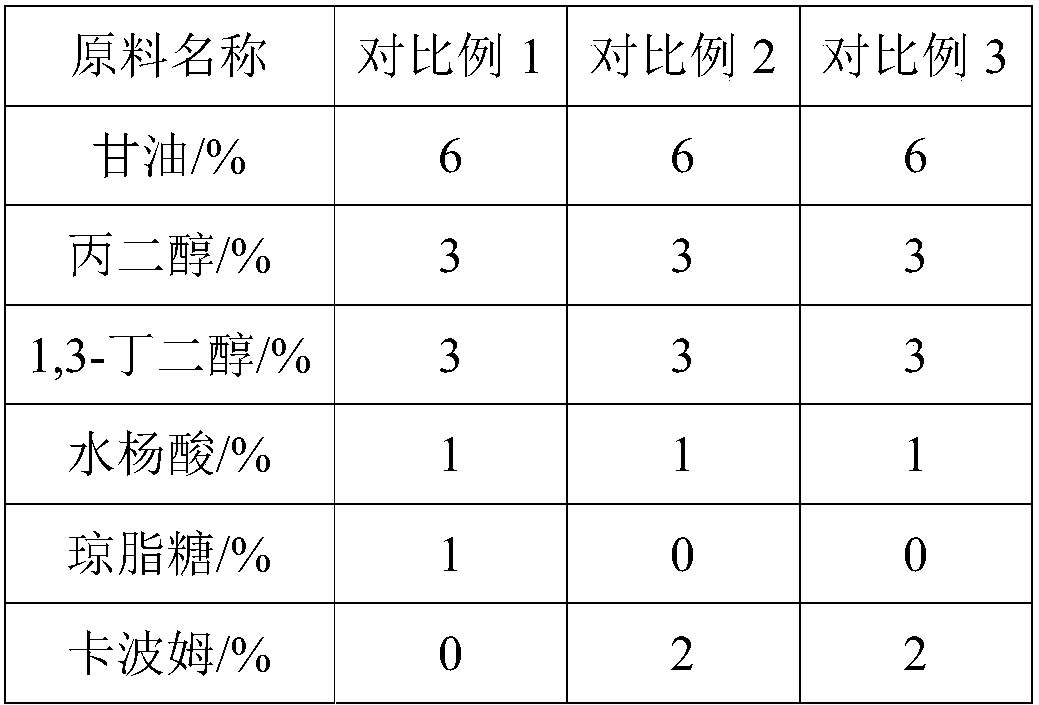

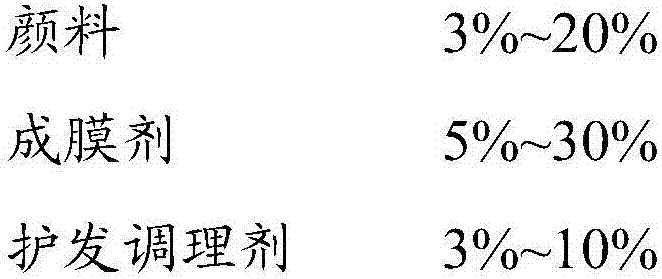

A smoothie acne-removing gel and its preparation method

ActiveCN109199895ANatural sourceLow costCosmetic preparationsToilet preparationsPreservativeSalicylic acid

The invention discloses a smoothie acne-removing acne gel and its preparation method. The smoothie acne-removing gel is prepared from humectant, acne-removing agent, bio-polysaccharide glue, preservative, pigment and water. A Chinese medicinal preparation is prepare by mixing humectant, bio-polysaccharide gum and acne-removing agent evenly, adde water, stirring, heating to dissolve completely, stir, cooling to 40-45 DEG C, adde preservative and pigment, and keeping stir; as that temperature drop to 32-37 DEG C, the stirring speed is adjust to high-speed stirring, the temperature drops further,and the stirring is maintain for 25-45 minutes after the temperature drops to room temperature. The acne removing gel is novel in appearance and rich in texture when used. And solves the problem thatthe common hydrogel is difficult to thicken salicylic acid, so that the salicylic acid maintains good acne removing activity.

Owner:广州玮弘祺生物科技有限公司

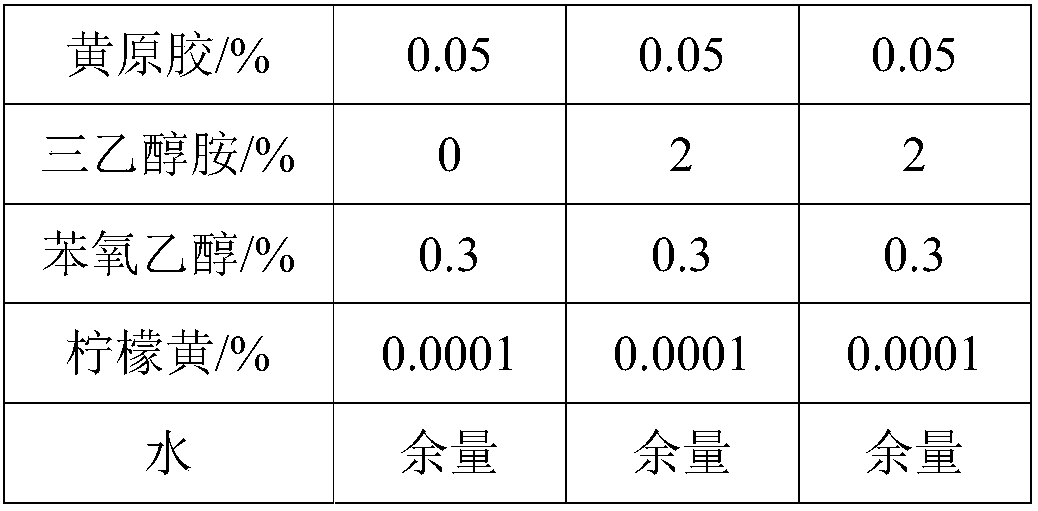

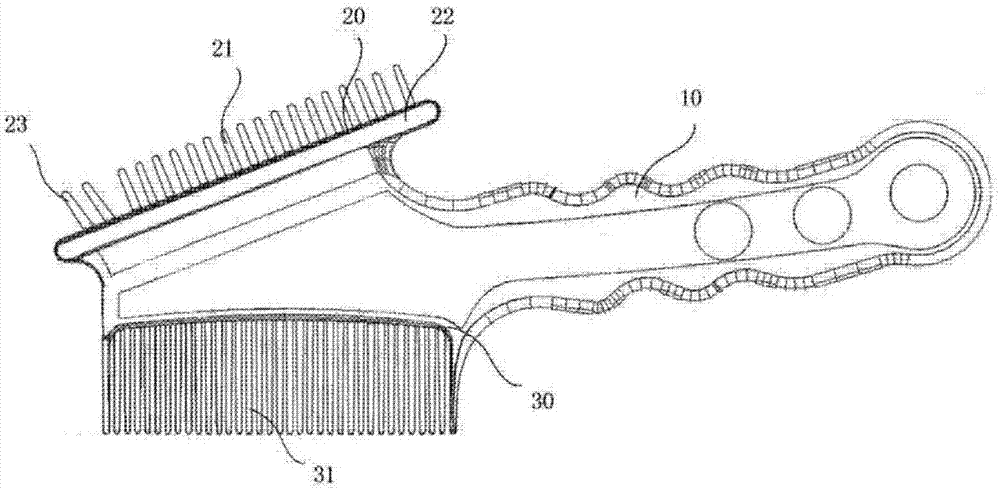

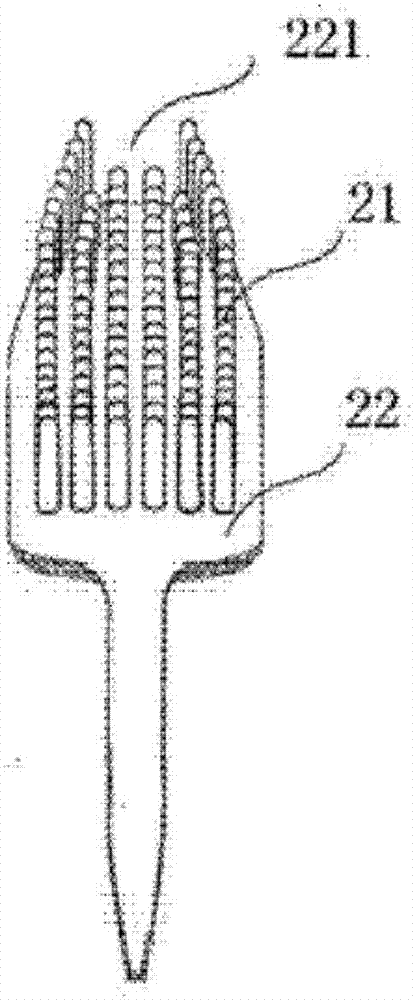

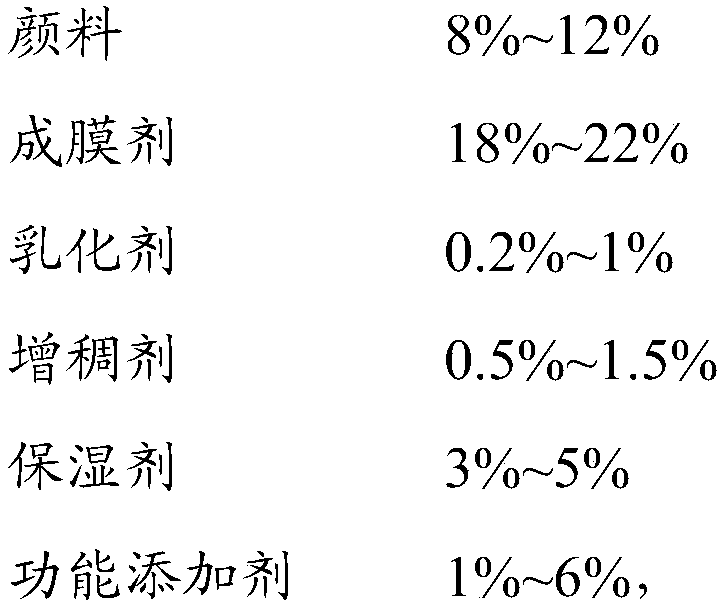

Hair-coloring elastin composition as well as preparation method and using method thereof

InactiveCN107496199AEasy to removeAchieve colorCosmetic preparationsHair cosmeticsColored hairHair Colors

The invention relates to a hair-coloring elastin composition as well as a preparation method and a using method thereof. The hair-coloring elastin composition is prepared from water and the following raw material components in percentage by weight: 1-20% of pigments, 1-30% of film forming agents, 0.1-10% of hair protecting and conditioning agents, 0.2-3% of emulsifying agents and 0.1-3% of thickening agents, wherein the film forming agents are selected from one or more of acrylic (ester) copolymers, polyurethane-14 / acrylic (ester) copolymers AMP salts; the pigments are cosmetic-grade coatings. The hair-coloring elastin composition is capable of uniformly and completely covering the whole hair at 360 degrees and is conveniently removed; the hair-coloring elastin composition can be removed by using hair shampoos with surfactants; the original hair color can be restored; the colors can be conveniently dyed, removed and replaced according to the requirements; the hair-coloring elastin composition can achieve one-time temporary coloring, has good hair protecting and coloring effects, and is free of strong shaping effect; the colored hair style is natural and smooth.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

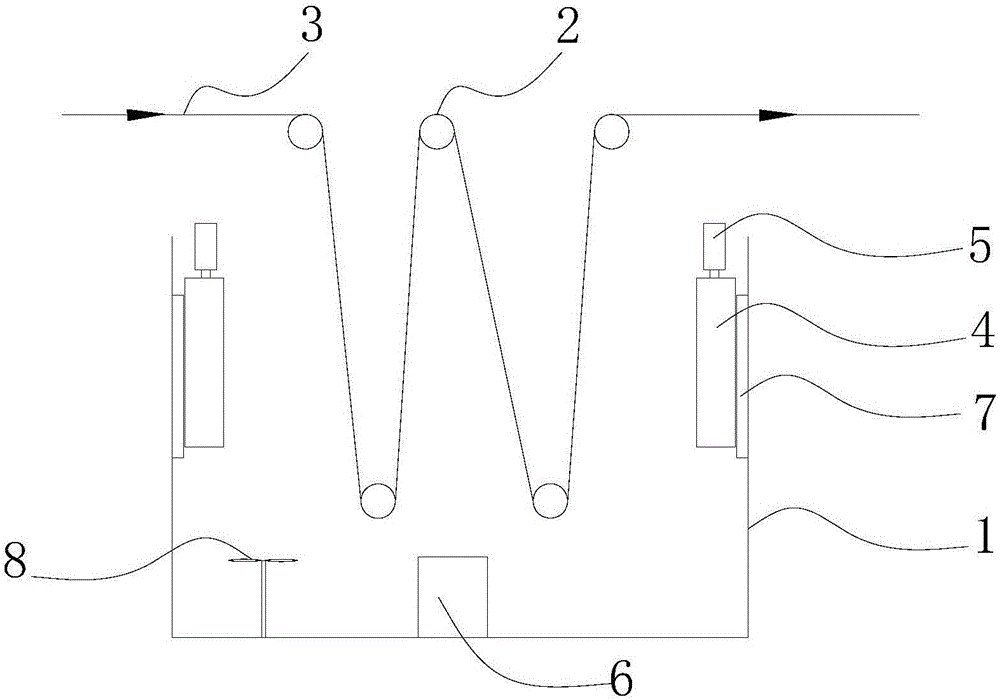

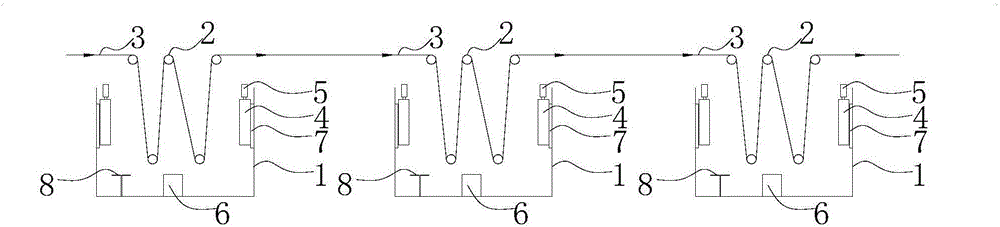

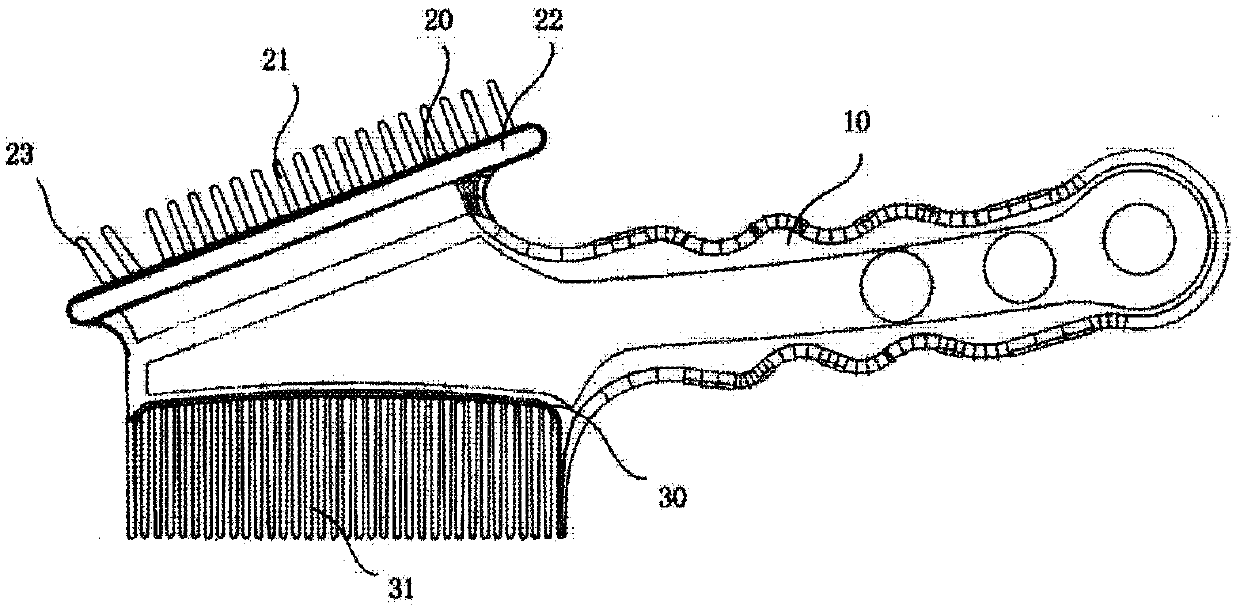

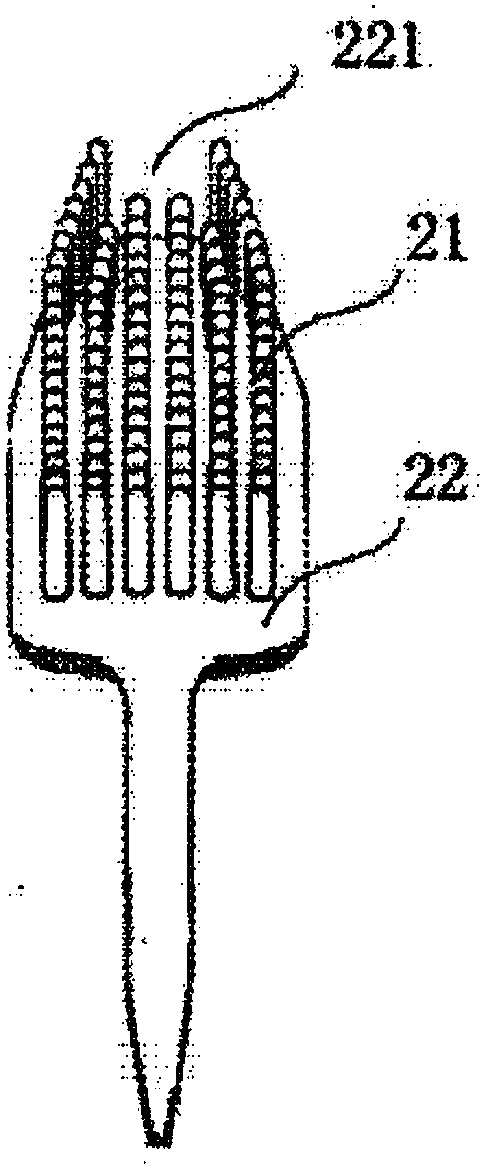

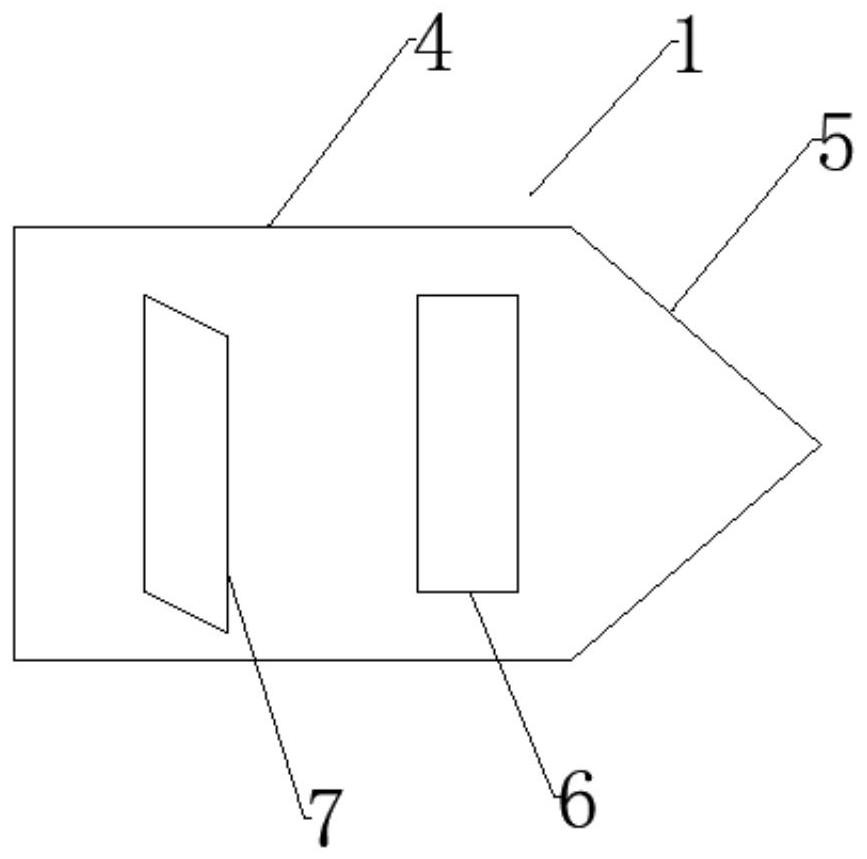

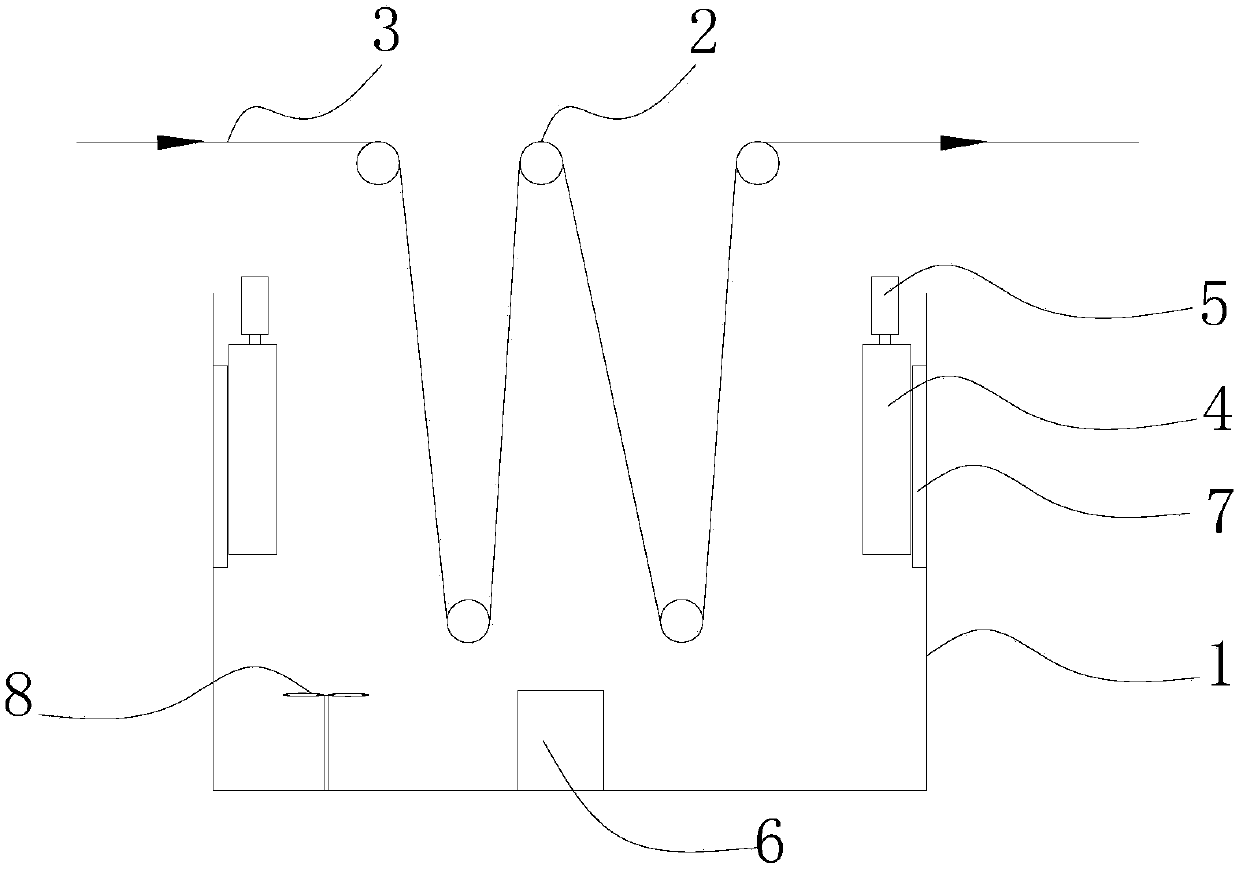

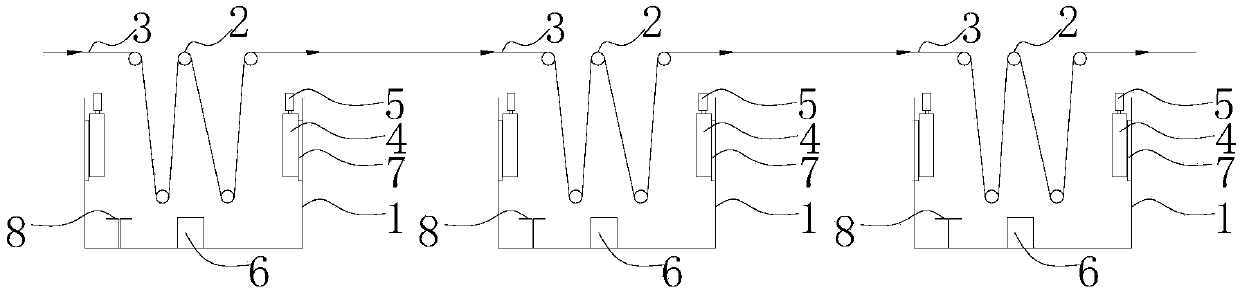

Ultrasonic washing tub and washed woven belt production line

ActiveCN105862294AAchieve cleaningEasy to dissolve and disperseTextile treatment machine arrangementsVibration treatmentProduction lineEngineering

The invention discloses an ultrasonic washing tub and a washed woven belt production line. The ultrasonic washing tub comprises a washing tub body. A plurality of transmission rollers are arranged in the washing tub body in an upper row and a lower row. The lower row of transmission rollers are soaked in water, and the upper row of transmission rollers and the lower row of transmission rollers are arrayed in a staggered mode. Woven belts are sequentially wound around the transmission rollers from left to right, soaked in water, washed and then output. A least two ultrasonic generation devices are arranged on the inner wall of the washing tub. The top of each ultrasonic generation device is connected with a speed sensor. A heating device is arranged at the bottom of the washing tub body. The effect of washing away dirt and greasy dirt on surfaces of the woven belts is improved, and the woven belts are more thoroughly washed. In addition, according to the washed woven belt production line manufactured through the ultrasonic washing tubs, the multiple ultrasonic washing tubs work at the same time, and washing efficiency is improved.

Owner:OPPERMANN WEBBING KUSN

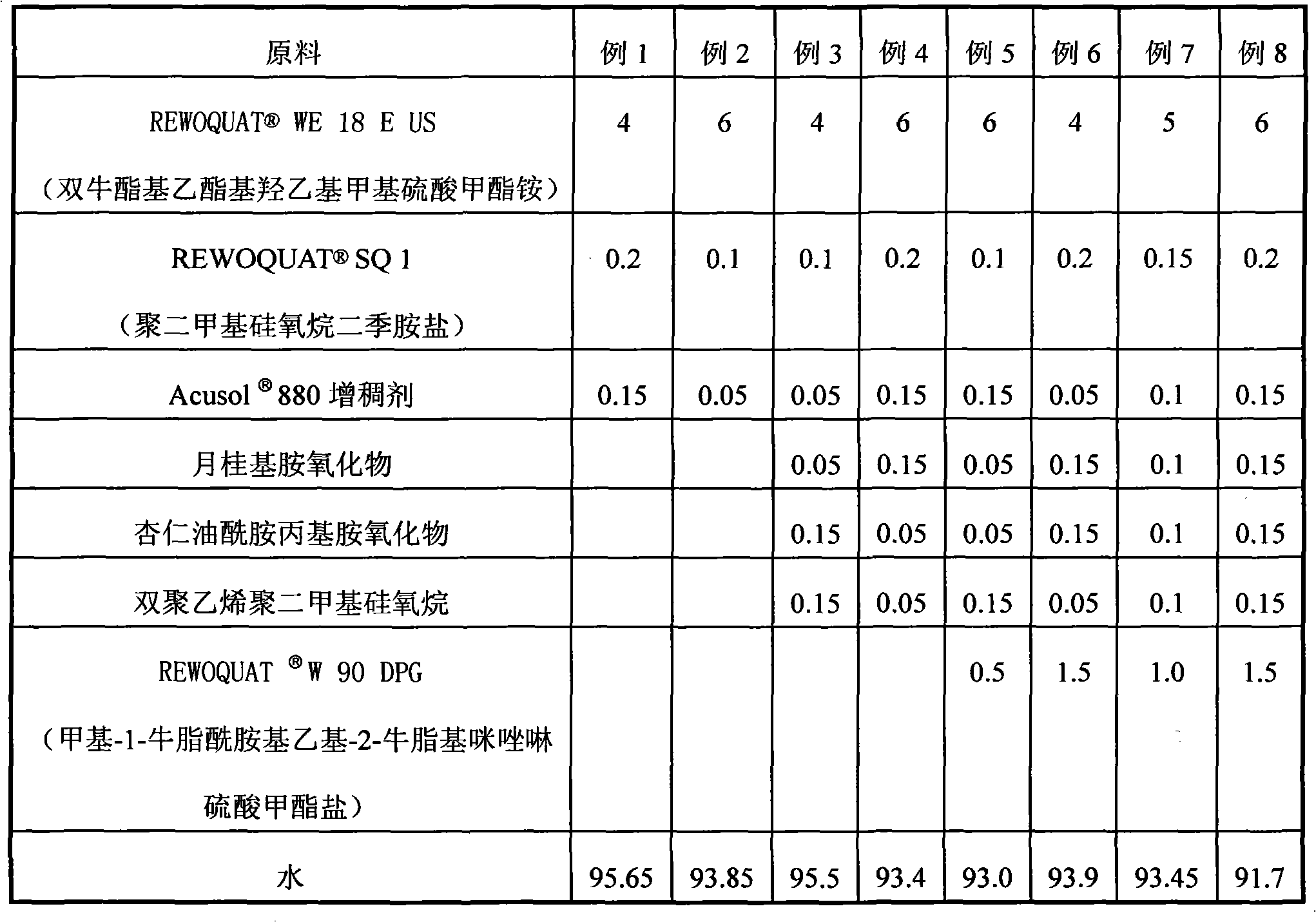

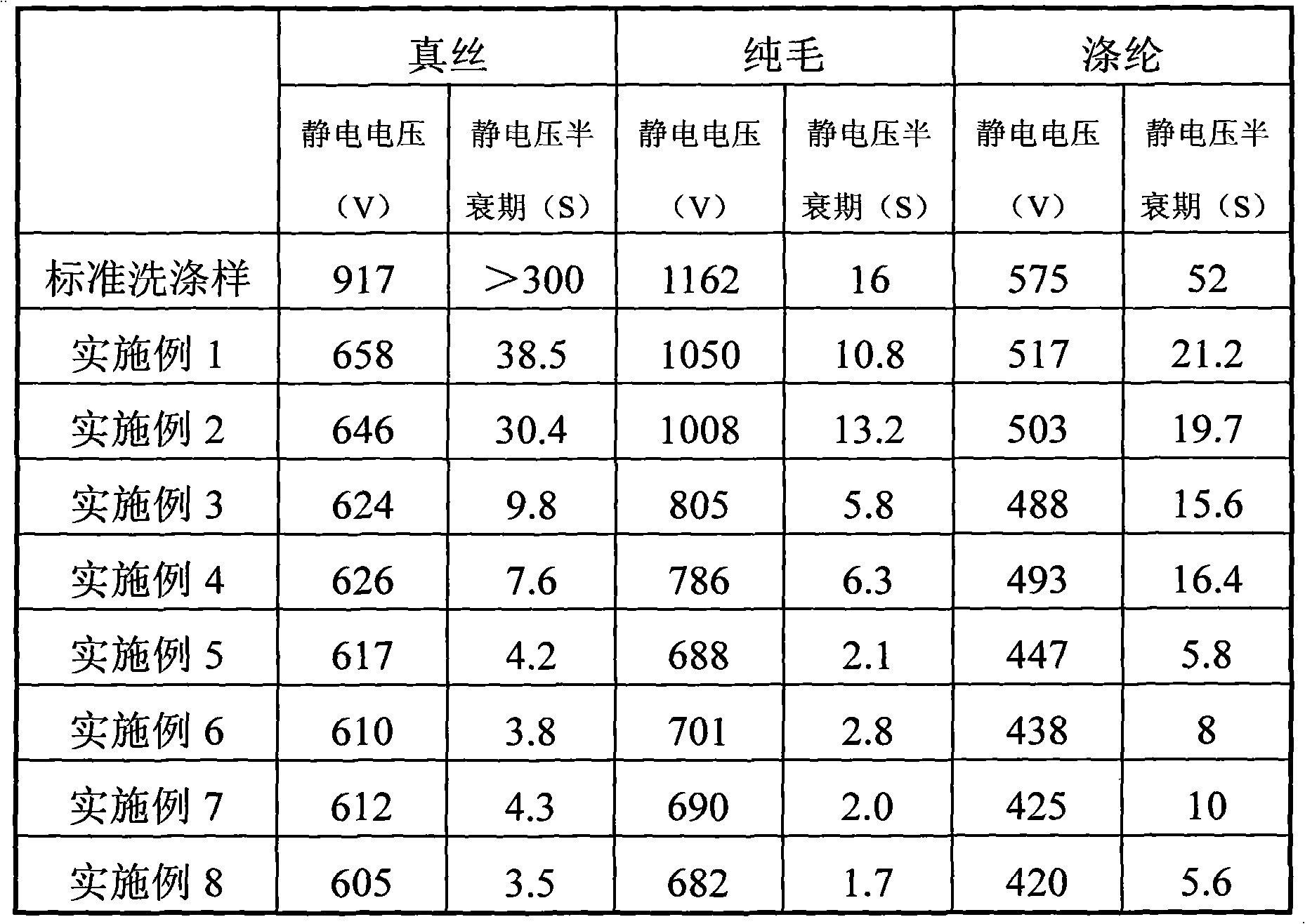

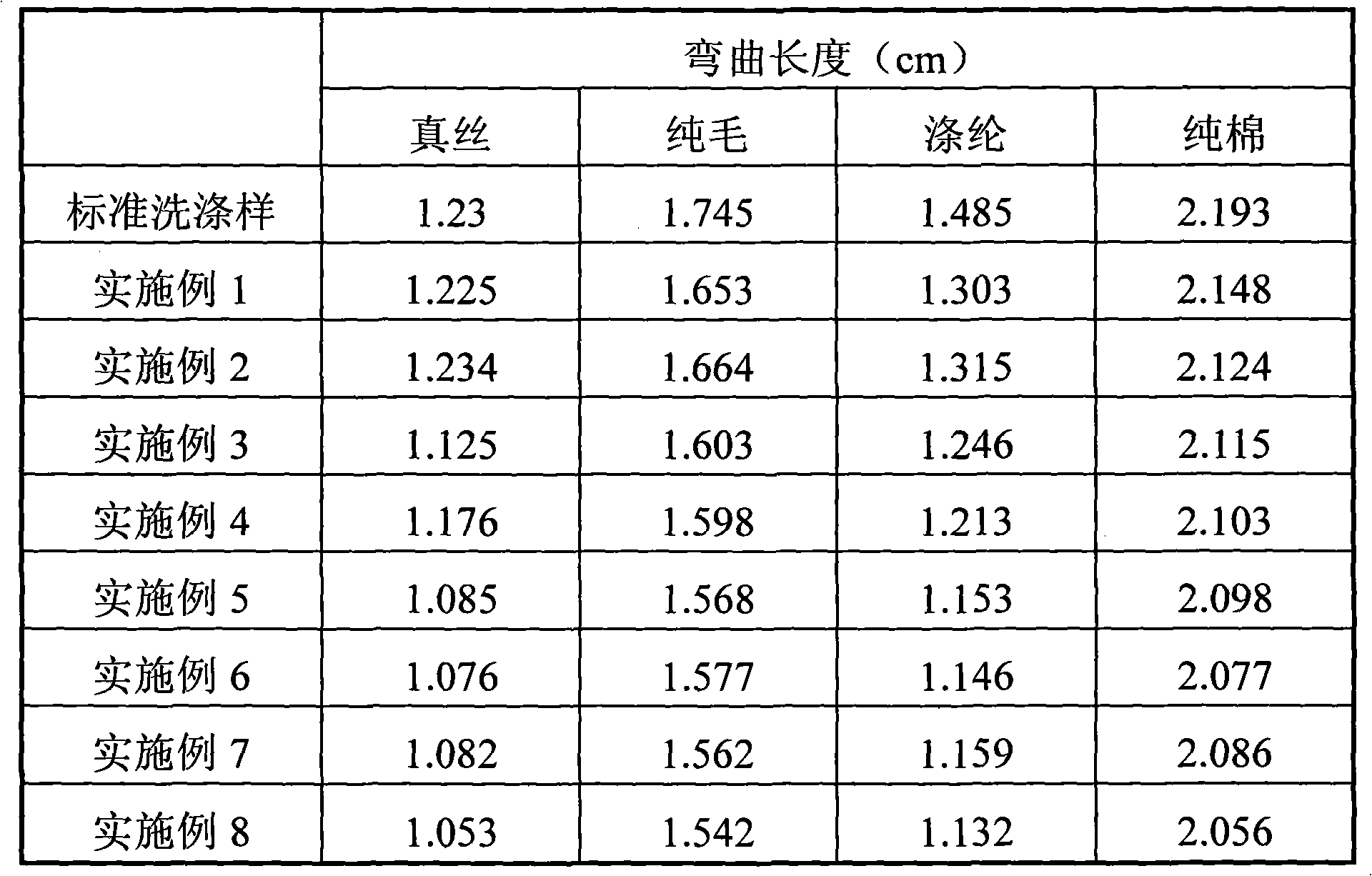

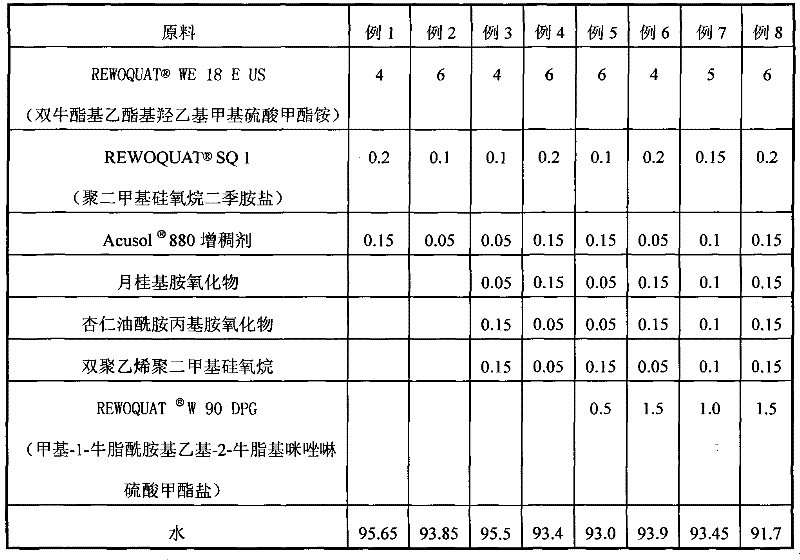

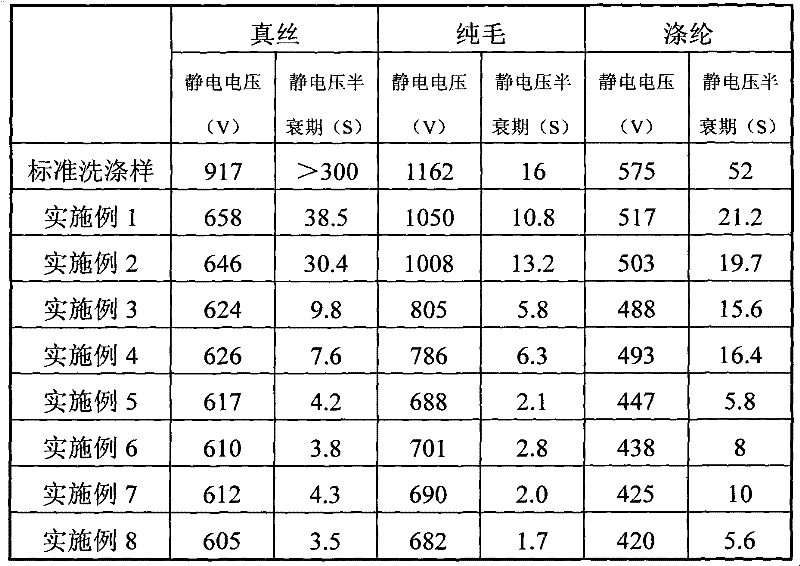

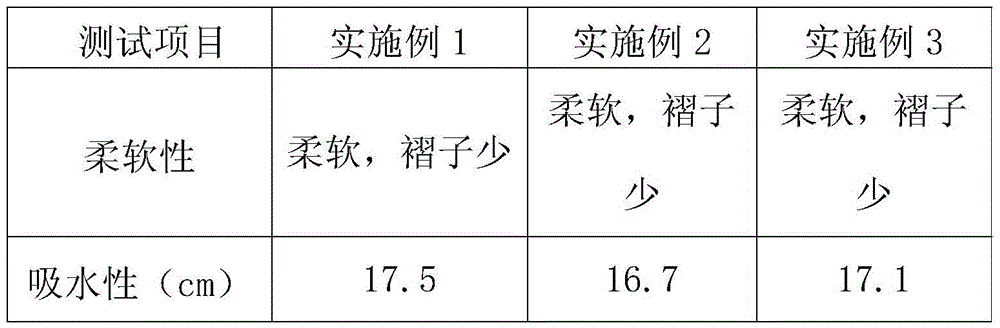

Clothes softener

ActiveCN101935949BClose to ph valueChange ionicityFibre treatmentDimethyl siloxanePolydimethylsiloxane

The invention discloses a clothes softener, which consists of the following components in percentage by weight: 4 to 6 percent of dihydrogenated tallowoylethyl hydroxyethylmonium methosulfate, 0.1 to 0.2 percent of polydimethylsiloxane diquaternary ammonium salt, 0.05 to 0.15 percent of thickener, 0.05-0.15 percent of lauryl amine oxide, 0.05-0.15 percent of almondamidopropyl amine oxide, 0.05-0.15 percent of bispolyethylene polydimethylsiloxane and the balance of water. Main raw materials used in the clothes softener are biodegradable, so the clothes softener is environment-friendly; when the softener is used after the clothes are washed, the clothes are softer, more comfortable and easier for ironing and airing; and the softener is dissolved and dispersed into water more easily, and is convenient to use. Coated essence also can be added into the softener, and the essence can be left on the washed clothes and can volatilize fragrance again in friction of the clothes, so joyful sense can be brought to people.

Owner:SHANGHAI SOAP FACTORY

Cleaning agent applicable to descaling of landfill leachate evaporator and preparation method and application thereof

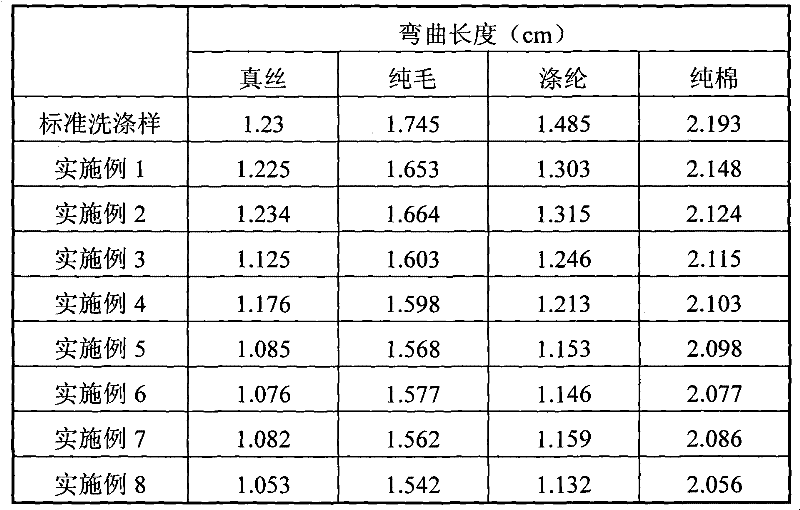

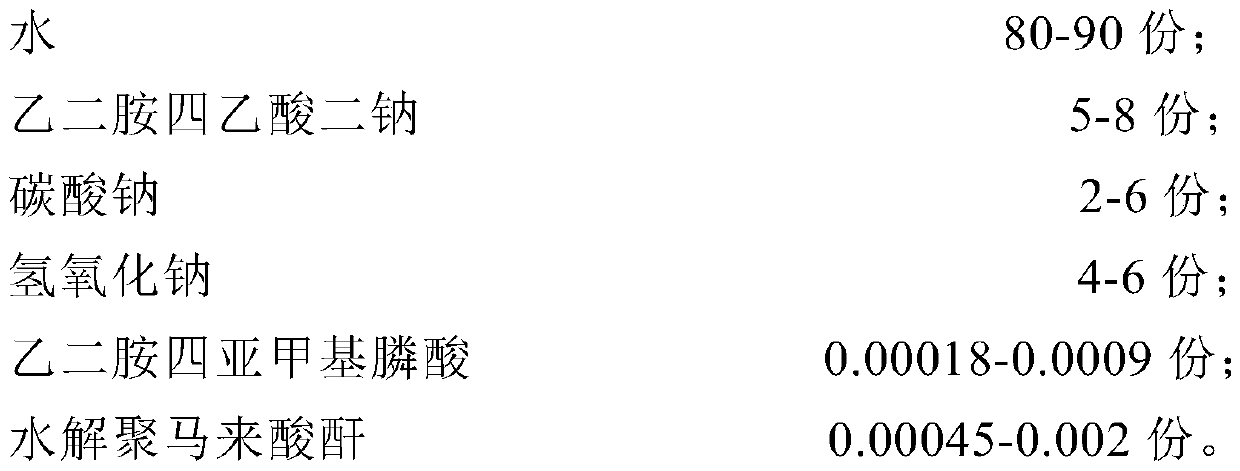

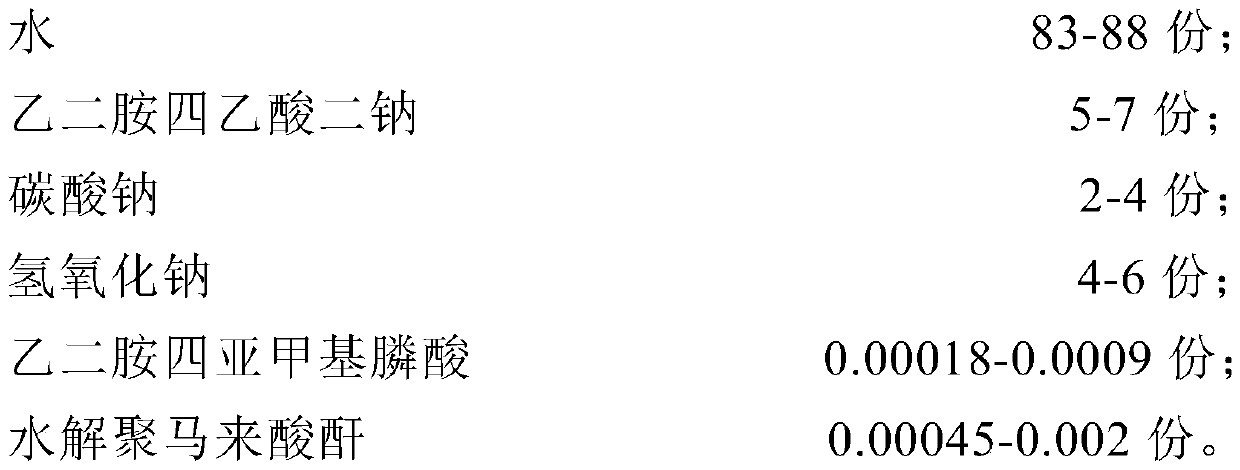

InactiveCN111205934ADirt hardImprove solubilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansing AgentsEthylenediaminetetra(methylenephosphonic)acid

The invention provides a cleaning agent applicable to descaling of a landfill leachate evaporator and a preparation method and application thereof, and the cleaning agent applicable to descaling of the landfill leachate evaporator is characterized by comprising the following components by weight: 80-90 parts of water; 5-8 parts of ethylenediamine tetraacetic acid disodium salt; 2-6 parts of sodiumcarbonate; 4-6 parts of sodium hydroxide; 0.00018-0.0009 parts of ethylenediamine tetramethylenephosphonic acid; 0.0003-0.0004 parts of sodium hydroxide; and 0.00045-0.002 parts of hydrolytic polymaleic anhydride. The invention further discloses a preparation method and application of the cleaning agent applicable to descaling of the landfill leachate evaporator. The cleaning agent can effectively soften and remove dirt generated by the landfill leachate evaporator in the landfill leachate treatment process, basically has no corrosion loss and side reaction to evaporation equipment, is simplein formula and good in descaling effect, and solves the problem of scaling of the landfill leachate treatment evaporator.

Owner:大连广泰源环保科技有限公司

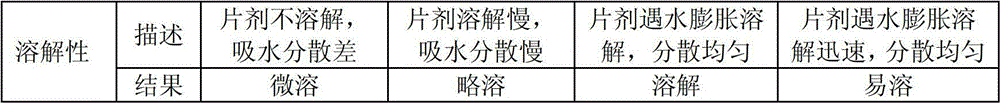

Preparation method of Chinese caterpillar fungus freeze-dried buccal tablet

ActiveCN102742838AEasy to carryEasy to dissolve and dispersePharmaceutical product form changeFood shapingFlavorFreeze-drying

The invention belongs to the field of healthcare food, and particularly relates to a preparation method of a Chinese caterpillar fungus freeze-dried buccal tablet. The preparation method aims at maintaining the original unique flavor of stews to a certain extent, preserving the nutritional ingredients for a long time and making the taking convenient. The preparation method of Chinese caterpillar fungus freeze-dried buccal tablet comprises the steps of: a, stewing or boiling the prepared stew raw materials to obtain a cooked product containing solid matters and soup; b, homogenizing the cooked product; c, filling the homogenized cooked product into a bubble cap of a bubble cap tray; d, carrying out freezing and vacuum drying to obtain the tablet; and e, carrying out aluminum foil sealing on the vacuum frozen and dried plastic bubble cap. The Chinese caterpillar fungus freeze-dried buccal tablet prepared by the preparation method provided by the invention is convenient for carrying, convenient for eating and suitable for the senile patients, the critical patients, the dysphagia patients, the infants, the children and the like, and has a good market prospect.

Owner:QINGHAI SPRING MEDICINAL RESOURCES TECHNOLOGY CO LTD

Hair color cream composition, as well as preparation method and use method of same

ActiveCN107595672AAchieve removalEasy to removeCosmetic preparationsHair cosmeticsFilm-forming agentColor changes

The invention relates to a hair color cream composition, as well as a preparation method and a use method of same. The hair color cream composition includes water, and the following raw materials including, by weight, 1-20% of pigment, 1-30% of a film-forming agent, and 0.1-6% of a substrate, wherein the film-forming agent includes one or more of acrylic (acrylate) copolymers and polyurethane-14 / acrylic (acrylate) copolymer AMP salts; the pigment is a cosmetic-grade coating. The hair color cream composition can uniformly and completely cover a whole hair in 360 degrees and is convenient to remove just by shampoo containing surfactants to restore the original color of hairs. The hair color cream composition can be used for dyeing hairs and allows color removal and color change conveniently,can achieve one-time temporary dyeing, has good dyeing effect and is free of strong hair fixing effect. The hair color cream composition can form natural and smooth hair style.

Owner:GUANGZHOU YOUNGRACE COSMETIC LTD

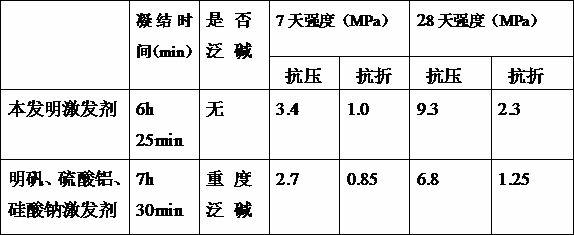

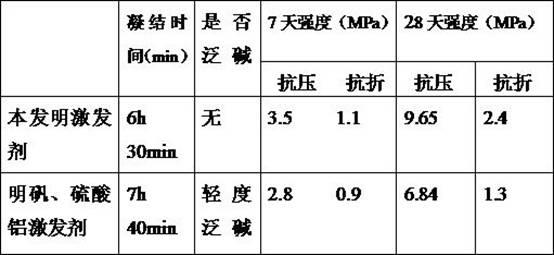

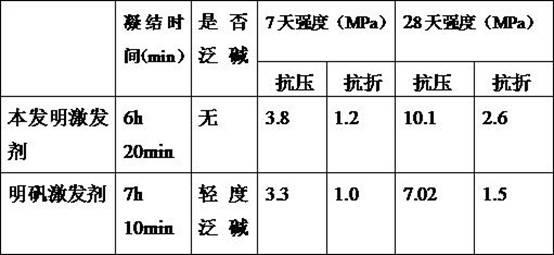

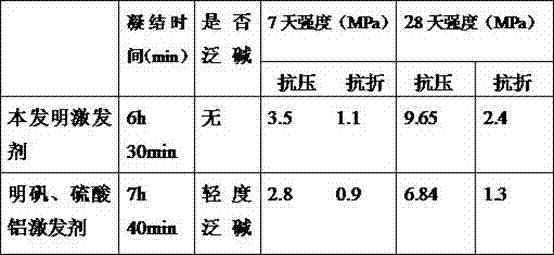

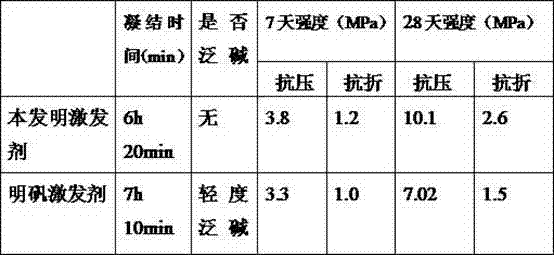

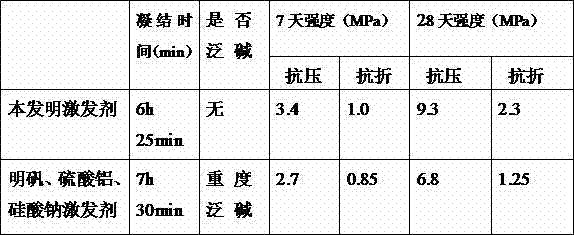

Calcination-free industrial gypsum byproduct dry-mixed mortar activator

The invention discloses a calcination-free industrial gypsum byproduct dry-mixed mortar activator, which belongs to the field of dry-mixed mortar additives. The dry-mixed mortar activator is prepared with the following mixed materials in part by weight: 10 to 25 parts of calcium chloride, 3 to 8 parts of calcium nitrite, 5 to 15 parts of triethanolamine, 5 to 15 parts of triisopropanolamine, 30 to 50 parts of industrial sugar residue, 10 to 30 parts of water and a plurality of parts of mountain flour. Compared with the prior art, the dry-mixed mortar activator is characterized in that: the application range is wide, efflorescence cannot take place, and the strength of mortar at each age can be enhanced.

Owner:SHANDONG CHENGHUA BUILDING MATERIAL TECH

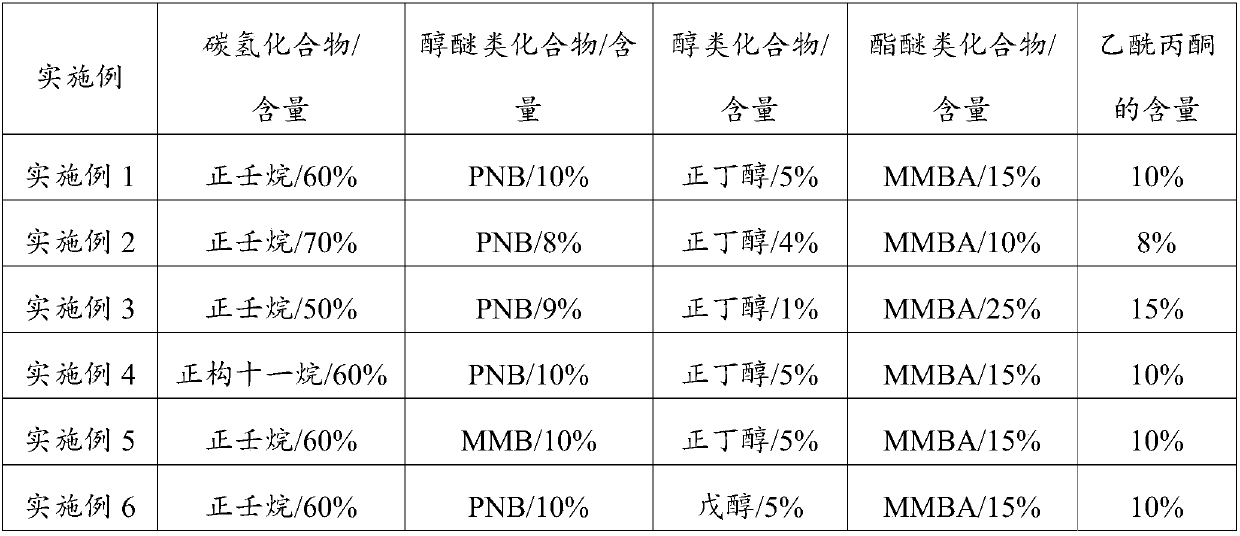

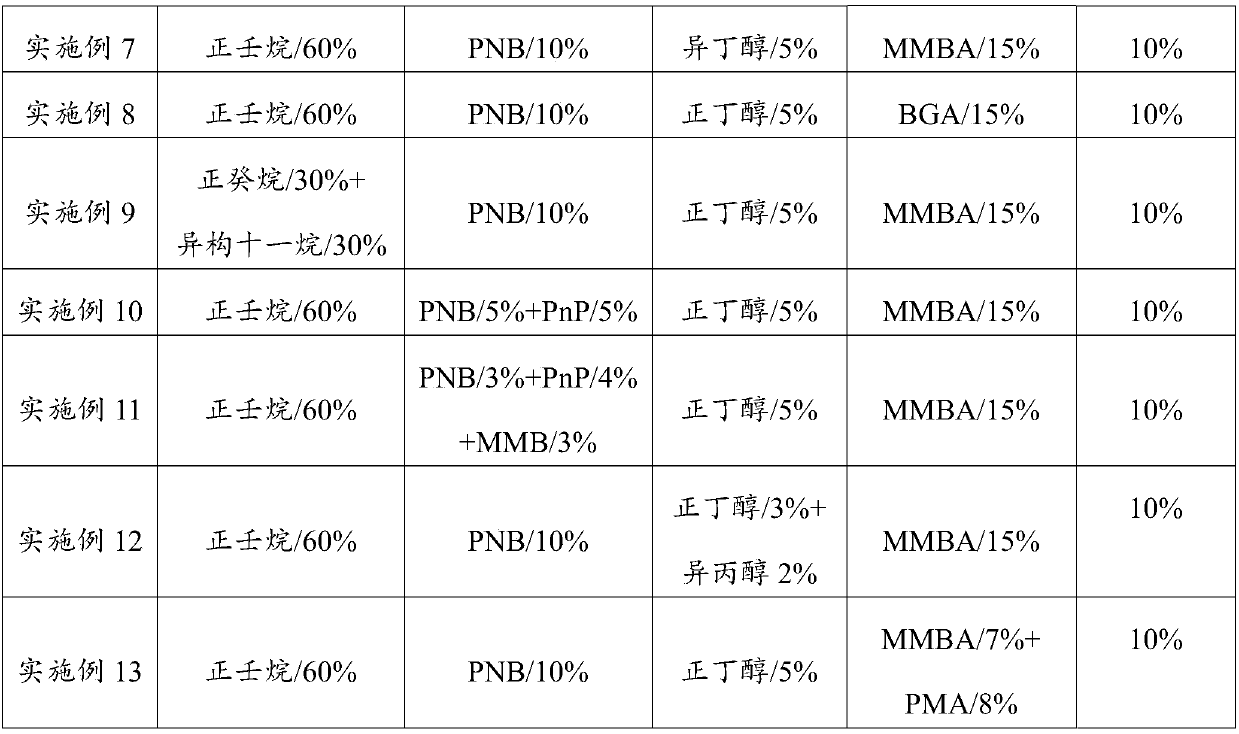

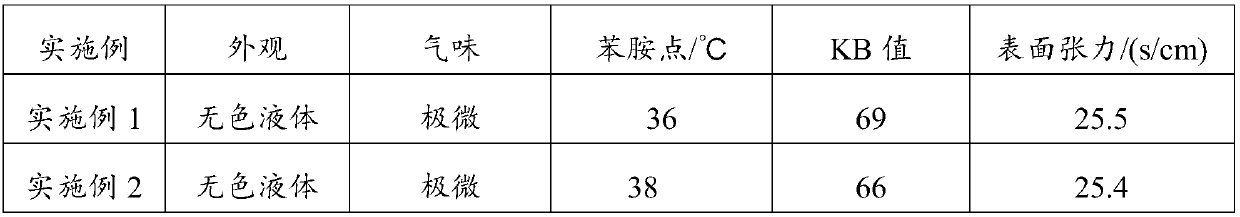

PCB (printed circuit board) ultrasonic hydrocarbon cleaner and application method thereof

InactiveCN109576089AImprove solubilityLow viscosityDetergent mixture composition preparationOrganic non-surface-active detergent compositionsPrinted circuit boardAcetone

The invention provides a PCB (printed circuit board) ultrasonic hydrocarbon cleaner and an application method thereof, wherein the PCB ultrasonic hydrocarbon cleaner includes, by weight, 50-70% of a hydrocarbon compound, 8-20% of an alcohol ether compound, 1-10% of an alcohol compound, 10-25% of an ester ether compound, and 8-15% of acetyl acetone. The hydrocarbon compound can remove nonpolar dirton a PB; the alcohol ether compound and the ester ether compound can dissolve in each other and help improve dissolubility of acetyl acetone in the hydrocarbon compound, so that polar dirt can be well removed; the alcohol compound can reduce the viscosity of the cleaner herein, so that ultrasonic washing is more sufficient and thorough; acetyl acetone can well soften, dissolve and disperse oil, can well dissolve rosin pollutants, and can chelate metal oxide pollutants on the PCB; the combination of acetyl acetone with the hydrocarbon compound, the alcohol ether compound, the alcohol compoundand the ester ether compound allows various pollutants on the surface of the PCB and in deep holes and blind holes to be ultrasonically cleaned.

Owner:广东新球清洗科技股份有限公司

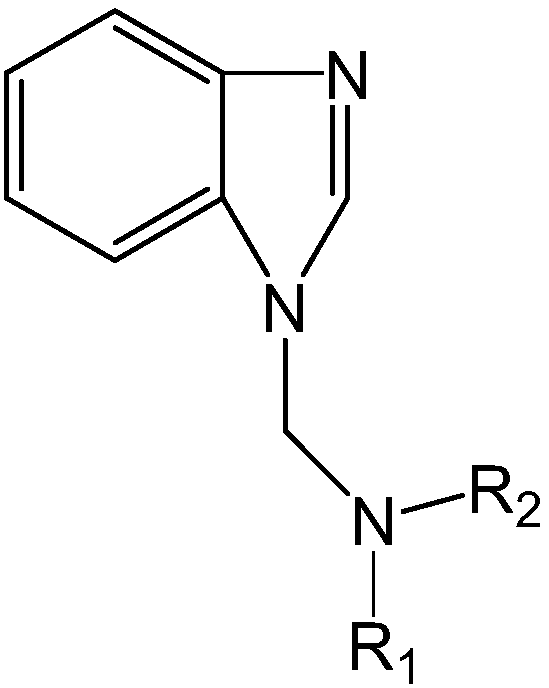

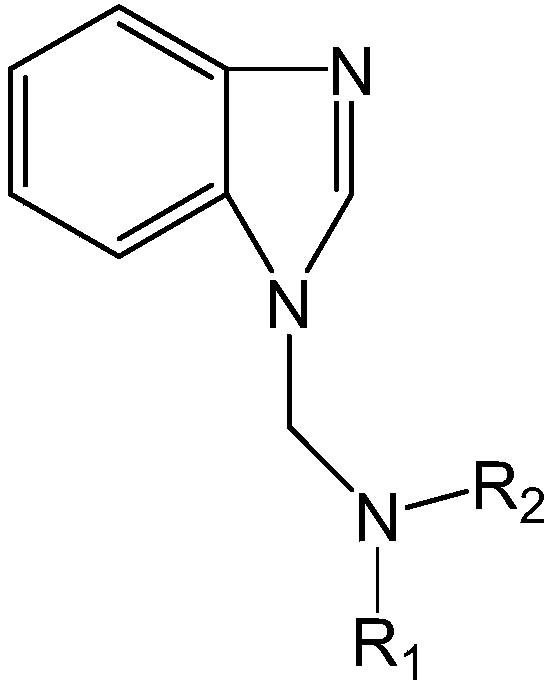

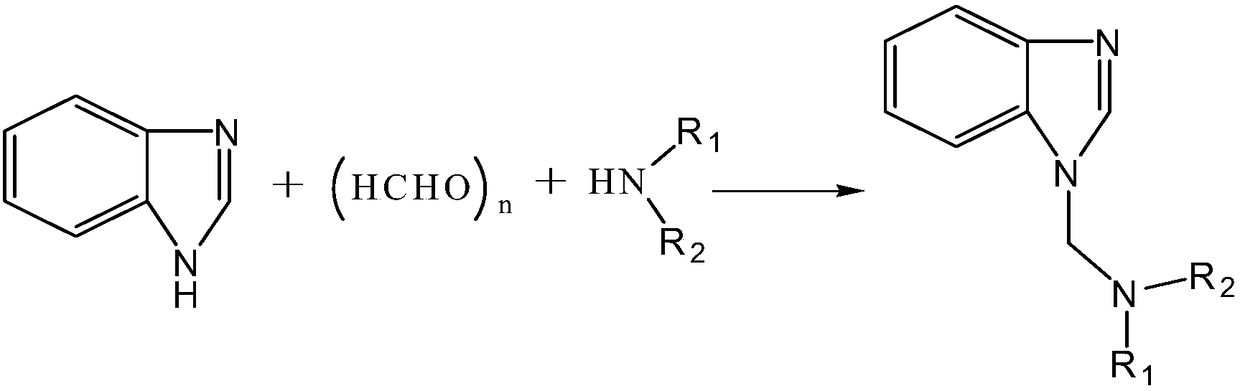

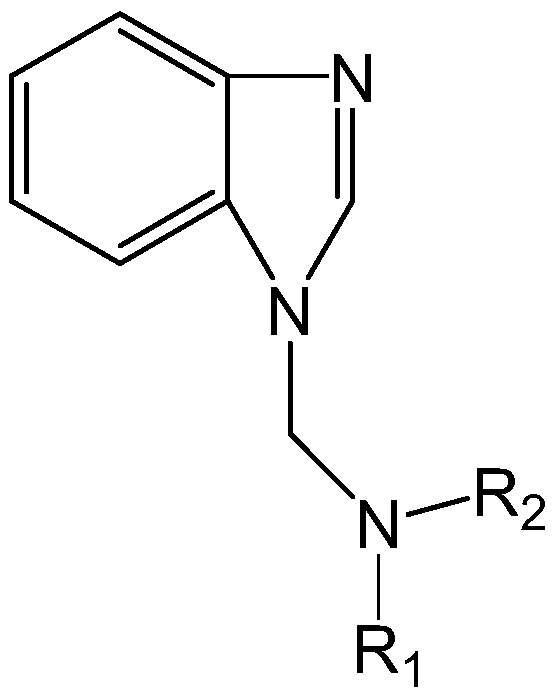

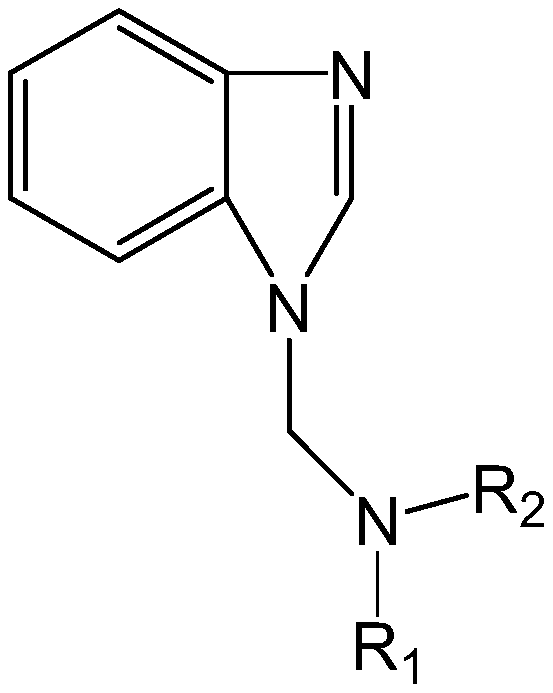

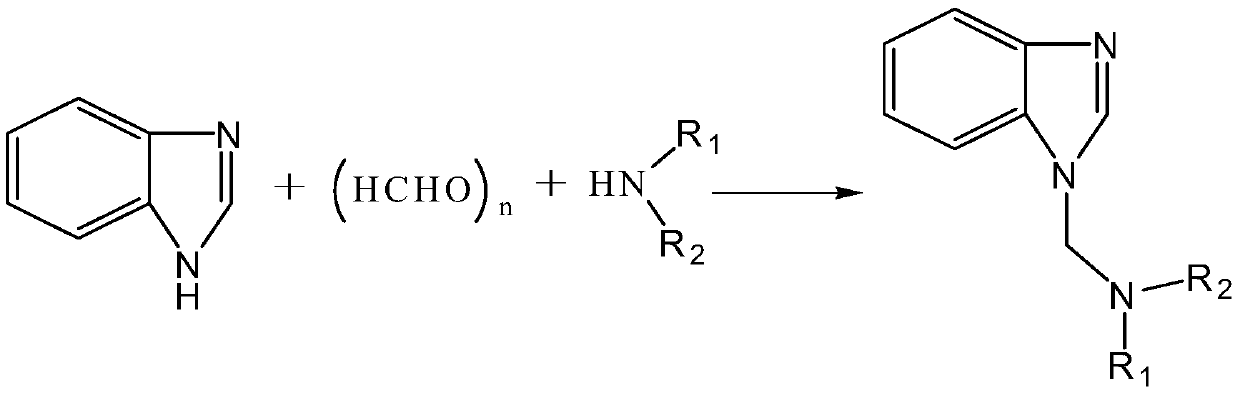

Mannich base acidizing corrosion inhibitor for organic acid system, and preparation method of Mannich base acidizing corrosion inhibitor

ActiveCN109265402AImprove adsorption firmnessGood compatibilityOrganic chemistrySolventBenzimidazole

The invention relates to a Mannich base acidizing corrosion inhibitor for an organic acid system, and a preparation method of the Mannich base acidizing corrosion inhibitor. The method comprises the steps of adding benzimidazole, aldehyde and organic amine into a container according molar ratio of 1 to (1.2-1.5) to 1, then adding toluene and mixing uniformly, and adjusting the pH value to 2-3 by using a catalyst; then, heating up to a reflux temperature of the toluene, and carrying out a reaction for 6h under the condition of heat preservation so as to obtain benzimidazole Mannich base; evenlymixing the following materials by mass percent: 10-15% of thiocyanate, 3-5% of alkynol, 5-10% of a surfactant, 40-62% of a solvent and 20-30% of the benzimidazole Mannich base so as to obtain the Mannich base acidizing corrosion inhibitor for the organic acid system. The Mannich base acidizing corrosion inhibitor for the organic acid system has an excellent protection effect on carbon steel oil pipes and equipment in a strong acid environment. The product solves the problem of corrosion of the organic acid system in an acidizing fracturing operation process, thus achieving the aim of protecting the oil pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

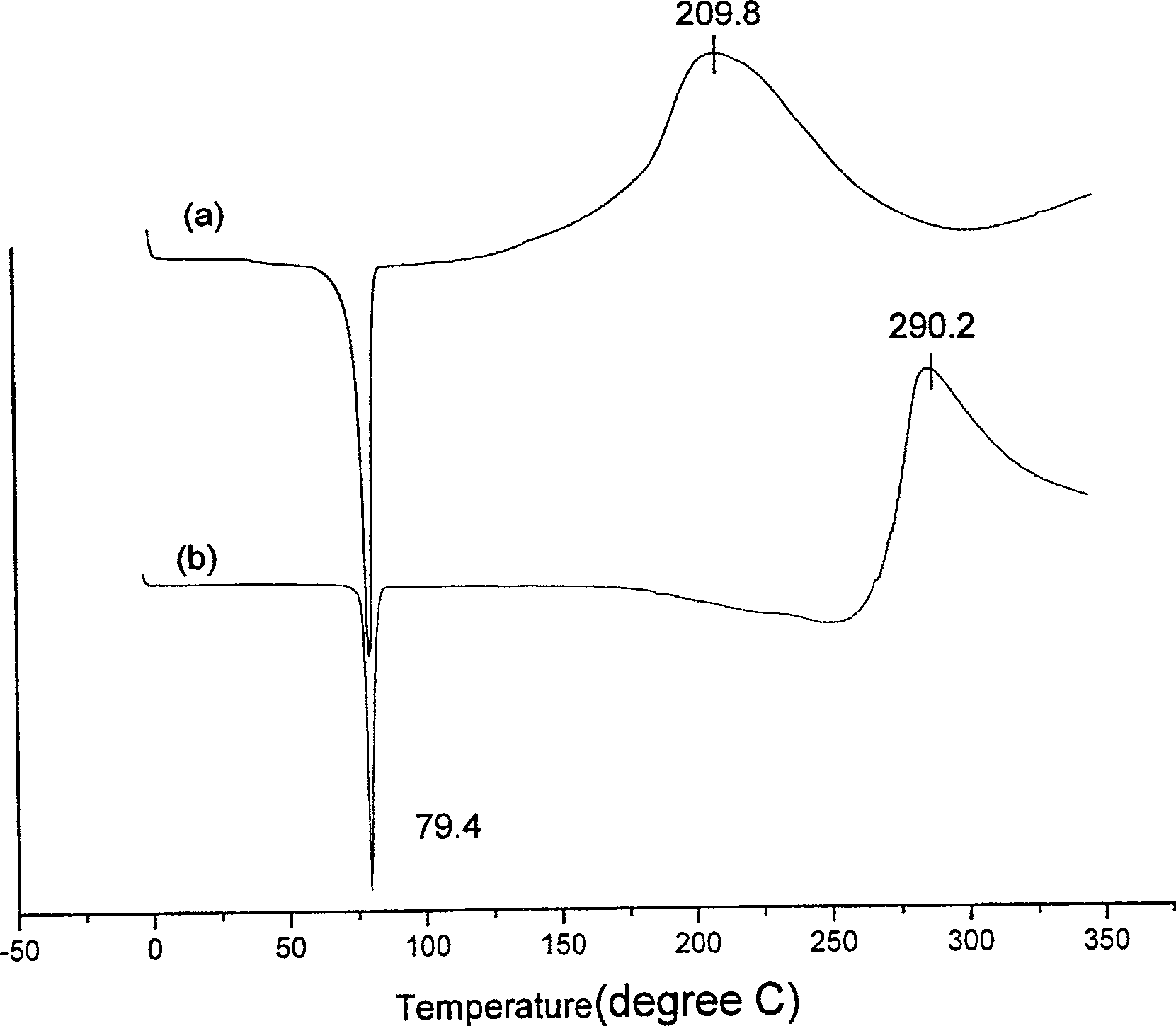

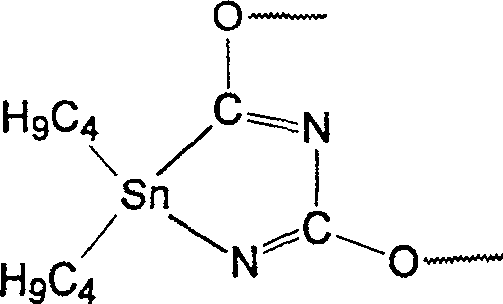

Double-component catalyst for cyanate solidification reaction and its preparing process

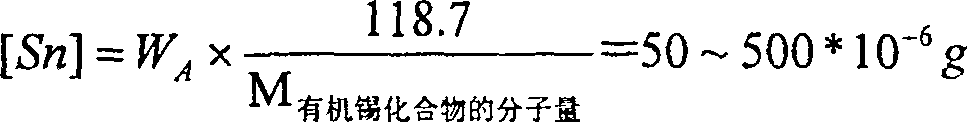

The invention discloses a composition of a two-component organotin compound catalyst and a preparation method thereof. The catalyst is mainly used in the curing reaction of cyanate resin. Its composition includes organotin compounds and reactive small molecule compounds. The molecular formula of the organotin compound is: (H9C4)2Sn(NCO-R-OCN)2; wherein the reactive small molecule compound acts as a reactive diluent, and it can polymerize to form a high polymer while the cyanate resin is curing. In order to improve the manufacturability, it will not adversely affect the performance of the cyanate ester cured resin. The preparation process of the two-component catalyst is that the above two components are stirred for 15-25 minutes under the heating condition of 40-80° C., and then naturally cooled to room temperature. The invention has high catalytic activity and selectivity, can be well dissolved and dispersed in the cyanate monomer, and is easy to weigh so as to control the dosage.

Owner:TONGJI UNIV

Preparation method of thermosensitive color change non-woven fabric

ActiveCN111101291AImprove toughnessHigh transparencyConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer sciencePolyethylene terephthalate

The invention relates to the technical field of a non-woven fabric, provides a preparation method of a thermosensitive color change non-woven fabric, and solves problems that in the prior art, a color-changing agent required for preparing thermosensitive color change fibers has a high requirement for temperature resistance, durability of the prepared thermosensitive color change fibers is reducedand the prepared thermosensitive color change fibers are poor in hand feeling. The preparation method comprises the following steps of: (1) using thermosensitive color change fibers and common ES fibers as raw materials of the thermosensitive color change non-woven fabric, wherein the thermosensitive color change fibers are of a skin-core type structure and comprise skin layers and core layers, each skin layer comprises the following raw materials in parts by weight: 0.8 to 3 parts of color fixative, 1 to 30 parts of color developing agent, 30 to 90 parts of polyethylene glycol 1500 and 60 to100 parts of polyethylene, and each core layer is polyethylene terephthalate; (2) respectively carrying out opening mixing, carding, hot air adhesion and cooling setting on the thermosensitive color change fibers and the common ES fibers to prepare a first non-woven fabric and a second non-woven fabric; and (3) carrying out online compounding on the first non-woven fabric and the second non-wovenfabric which are prepared in the step (2).

Owner:FUJIAN HENGAN HLDG CO LTD +2

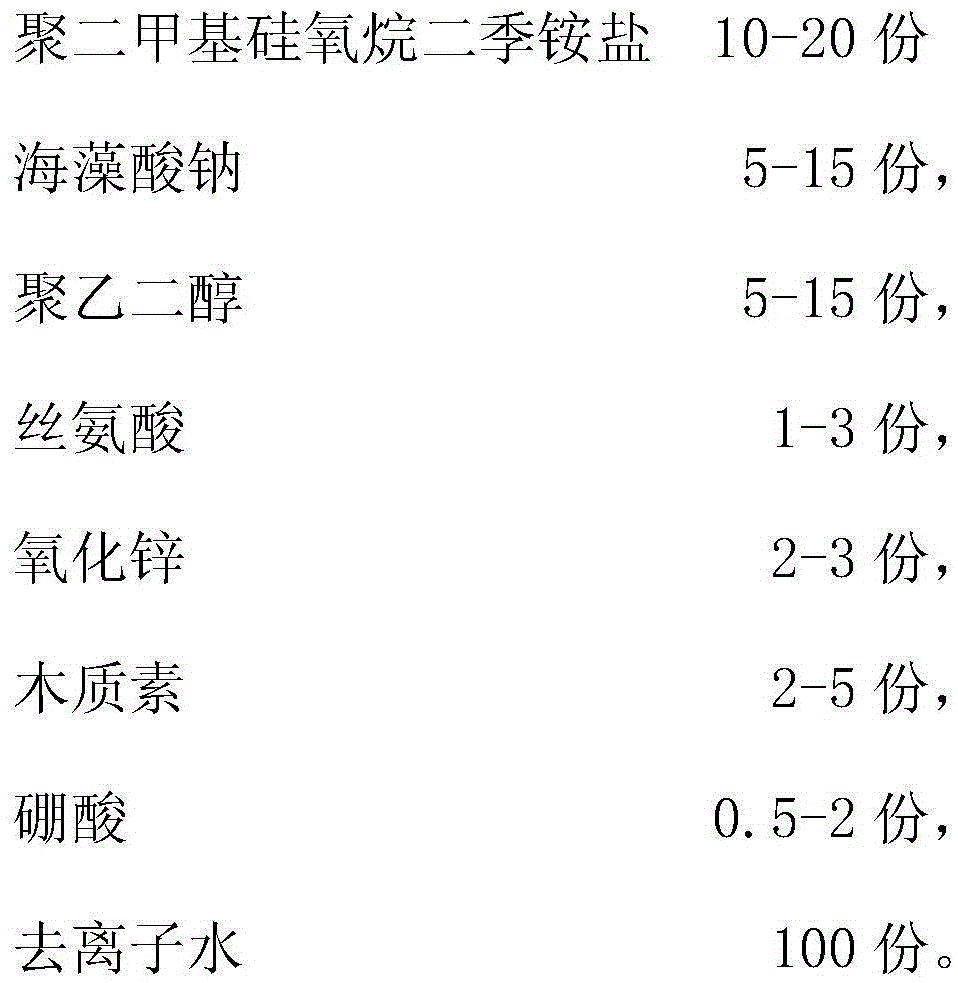

Destaticizer, preparation method and textile materials containing destaticizer

InactiveCN105064021AEasy to dissolve and disperseImprove stabilityFibre treatmentPolyvinyl alcoholDimethyl siloxane

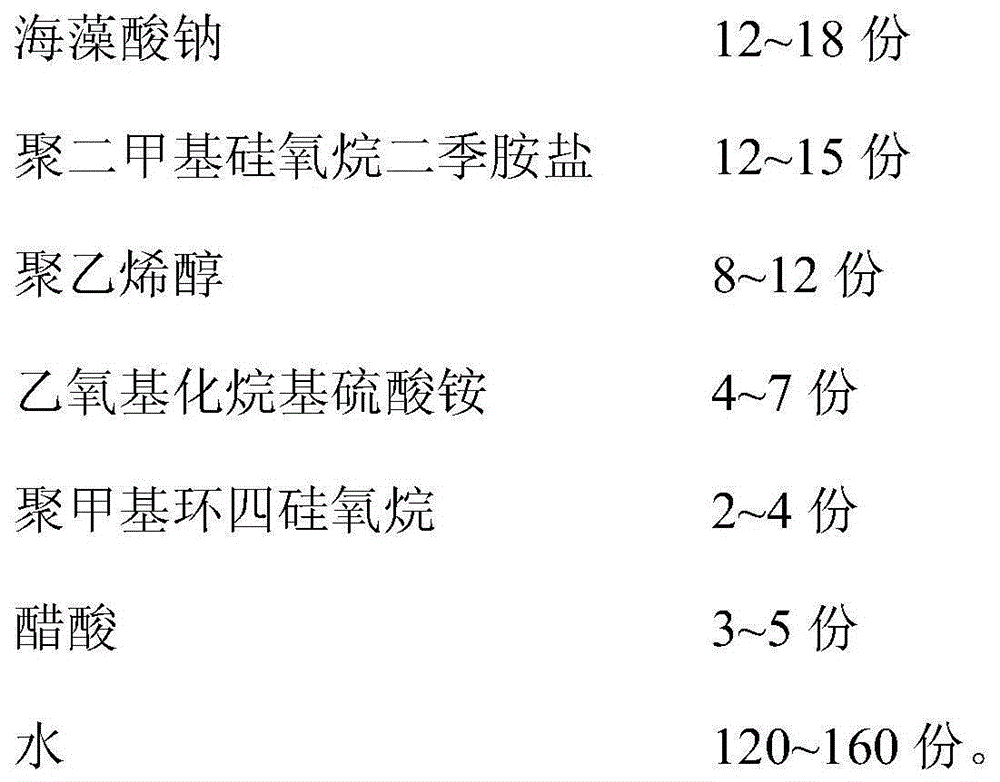

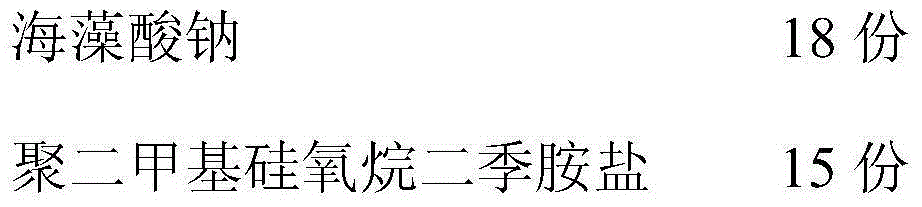

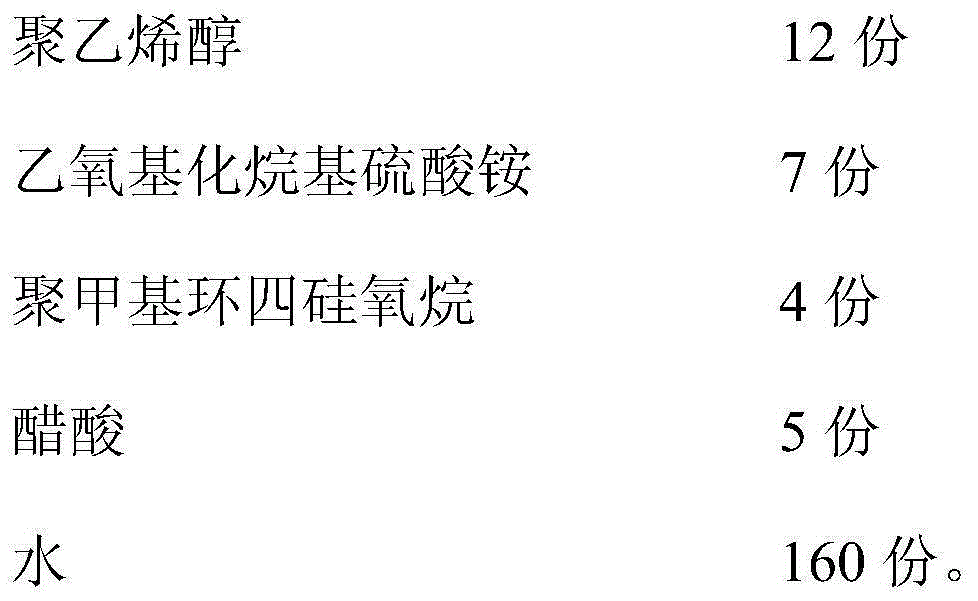

The invention provides a destaticizer for textile materials, a preparation method and the textile materials containing the destaticizer. The destaticizer is mainly prepared from the following raw materials in parts by weight: 12 to 18 parts of sodium alginate, 12 to 15 parts of polydimethylsiloxane divalent quaternary ammonium, 8 to 12 parts of polyvinyl alcohol, 4 to 7 parts of ethoxylation alkyl ammonium sulfate, 2 to 4 parts of polymethyl cyclotetrasiloxane, 3 to 5 parts of acetic acid and 120 to 130 parts of water. The destaticizer has excellent and permanent anti-static performance and can be used for static resistance of fabrics.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Curing agent intermediate composition and curing agent employing the same

InactiveCN101113229AEasy to dissolve and disperseGood storage stabilityMasterbatchIntermediate composition

The invention provides a curing agent intermediate composite for preparing latent curing agent, comprising a first masterbatch and a second masterbatch, wherein, the first masterbatch is an addition product masterbatch obtained from the reaction of E-51 epoxy resin and 2-methylimidazole, the second masterbatch is the addition product masterbatch obtained from the reaction of bisphenol A epoxy resin and 2-phynelimidazol. The curing agent intermediate composite comprises 25wt percent -75wt percent of the first masterbatch and 25wt percent-75wt percent of the second masterbatch. The invention further provides a curing agent based on the curing agent intermediate composite. The curing agent masterbatch prepared by the curing agent intermediate composite of the invention can be dissolved and dispersed in the epoxy resin with more than 6 months of storage period and good storing stability. Besides, the curing agent requires lower curing temperature of 80 DEG C to the lowest extent, and has rapid curing speed, stable communication and resistance under the working environment of packaging of microelectronic products, simple preparation technique and is easy to be processed.

Owner:GUANG DONG DONGBOND TECH CO LTD

A kind of preparation method of thermosensitive discoloration non-woven fabric

ActiveCN111101291BImprove toughnessHigh transparencyConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer sciencePolyethylene terephthalate glycol

The invention relates to the technical field of non-woven fabrics, and provides a method for preparing heat-sensitive color-changing non-woven fabrics, which solves the high temperature resistance requirements of the color-changing agent required to prepare heat-sensitive color-changing fibers in the prior art and the durability of the prepared heat-sensitive color-changing fibers. The problem of loss and poor hand feeling includes the following steps: (1) using heat-sensitive color-changing fiber and ordinary ES fiber as the raw material of heat-sensitive color-changing non-woven fabric; the heat-sensitive color-changing fiber is a skin-core structure, including a skin layer and a core layer, the skin layer includes the following raw materials in parts by weight: 0.8 to 3 parts of color developing agent, 1 to 30 parts of color developing agent, 30 to 90 parts of polyethylene glycol 1500, 60 to 100 parts of polyethylene, and the core layer is Polyethylene terephthalate; (2) heat-sensitive color-changing fibers and ordinary ES fibers are respectively subjected to loosening and mixing, carding, hot-air bonding, cooling and setting to obtain the first non-woven fabric and the second non-woven fabric; (3) Composite the first non-woven fabric and the second non-woven fabric prepared in step (2) online.

Owner:FUJIAN HENGAN HYGIENE MATERIAL

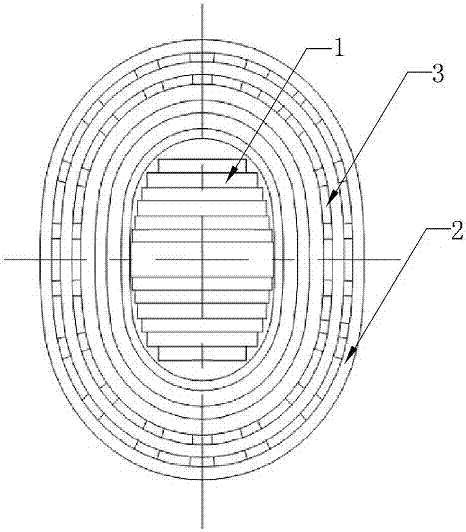

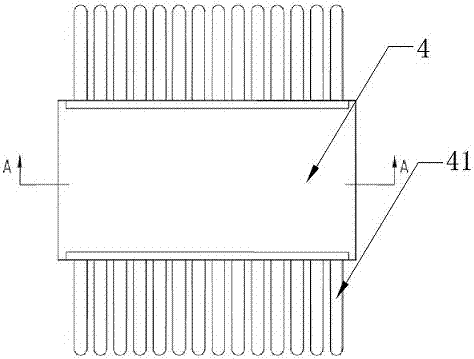

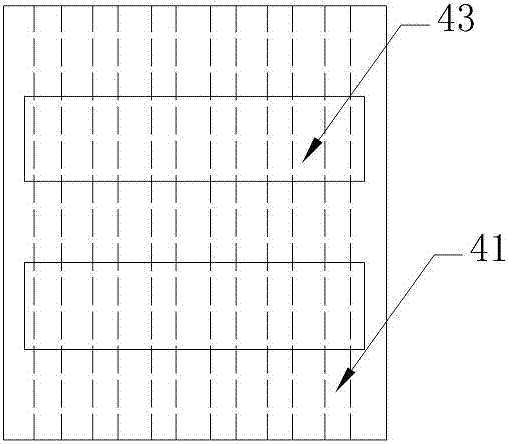

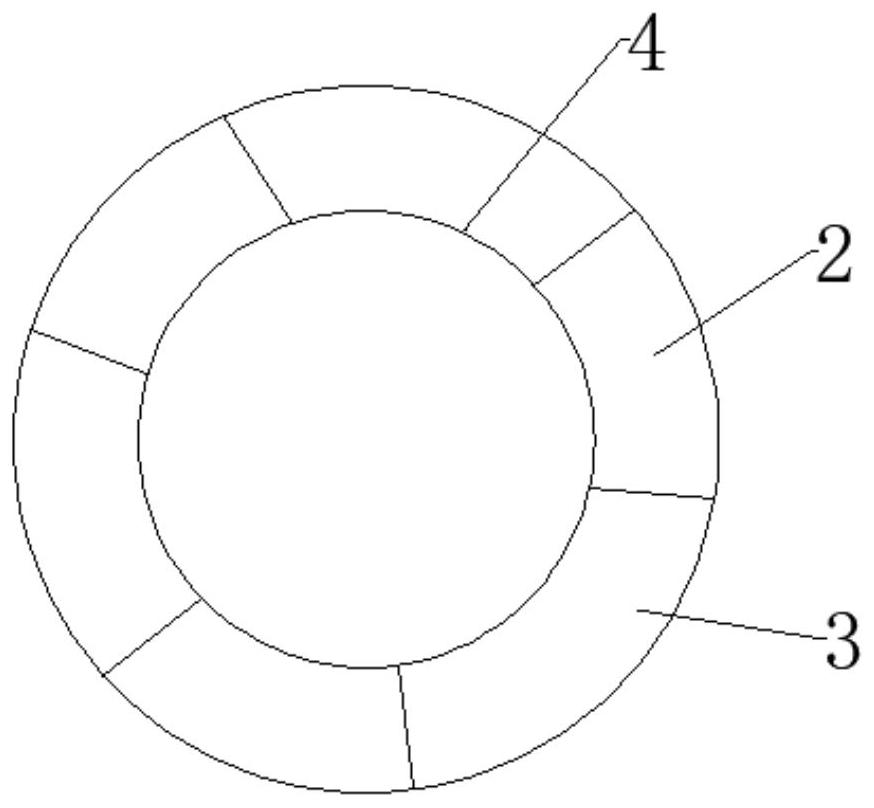

High-overload transformer

InactiveCN106920649AImprove cooling effectReduce the quantity requiredTransformers/inductances coolingTransformers/inductances coils/windings/connectionsLow voltageTransformer

The invention relates to a high-overload transformer. In order to solve the problems of high material consumption, poor heat dissipation effect and the like of a high-overload transformer which is frequently used in domestic, the high-overload transformer which is low in loss and good in heat dissipation is provided. The high-overload transformer comprises an iron core, a high-voltage winding, a low-voltage winding and an oil tank, wherein a low-voltage coil is wound around one side of the iron core, a high-voltage winding is wound around the other side of the iron core, the iron core, the low-voltage coil and the high-voltage coil are arranged in the oil box, the iron core is of an oval structure formed by laminating high-magnetic conduction silicon steel or amorphous alloy, the magnetic flux density of the iron core is smaller than 1.68T, the low-voltage winding employs a paper covered rectangular wire, the current density of the low-voltage winding is smaller than 3.5A / mm<2>, the high-voltage winding is of an oval multi-layer cylindrical structure, and a heat dissipation structure of the oil tank is a partition plate heat dissipation structure.

Owner:CHONGQING XIANGLONG ELECTRIC

A kind of organic acid system Mannich base acidification corrosion inhibitor and preparation method thereof

ActiveCN109265402BAdsorption is stable and denseImprove adsorption firmnessOrganic chemistryPtru catalystActive agent

The invention relates to a Mannich base acidizing corrosion inhibitor for an organic acid system, and a preparation method of the Mannich base acidizing corrosion inhibitor. The method comprises the steps of adding benzimidazole, aldehyde and organic amine into a container according molar ratio of 1 to (1.2-1.5) to 1, then adding toluene and mixing uniformly, and adjusting the pH value to 2-3 by using a catalyst; then, heating up to a reflux temperature of the toluene, and carrying out a reaction for 6h under the condition of heat preservation so as to obtain benzimidazole Mannich base; evenlymixing the following materials by mass percent: 10-15% of thiocyanate, 3-5% of alkynol, 5-10% of a surfactant, 40-62% of a solvent and 20-30% of the benzimidazole Mannich base so as to obtain the Mannich base acidizing corrosion inhibitor for the organic acid system. The Mannich base acidizing corrosion inhibitor for the organic acid system has an excellent protection effect on carbon steel oil pipes and equipment in a strong acid environment. The product solves the problem of corrosion of the organic acid system in an acidizing fracturing operation process, thus achieving the aim of protecting the oil pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Formulated solid ice cream and production method thereof

The invention discloses a formulated solid ice cream and a production method thereof, and belongs to the field of nutrition and health care diet. The ice cream comprises the following raw materials: milk powder, egg powder, sugar powder, an adhesive, an emulsifier, a stabilizer, and milk essence. The production method of the formulated solid ice cream comprises the following steps: well mixing the milk powder, the egg powder, the white sugar powder, sieving by an 80-100 mesh sieve; adding the adhesive after well mixing, sieving by a 12-14 mesh sieve to obtain soft particles; performing sterilization in a drying oven, collecting dried and sterilized particles, mixing with the emulsifier and the stabilizer; cooling, injecting the milk essence, sealing with a cover, sieving by a 10-mesh sieve to obtain particle solid ice cream. The ice cream of the invention contains the emulsifier and the stabilizer, has strong recoverability, and is easy to dissolve and disperse. In addition, the solidice cream of the invention is presented in a particle or block form, is stable in quality, difficult for microbiological contamination, long in shelf life, convenient for carrying, storage and transport, and is a qualified health care drink.

Owner:黄成宇

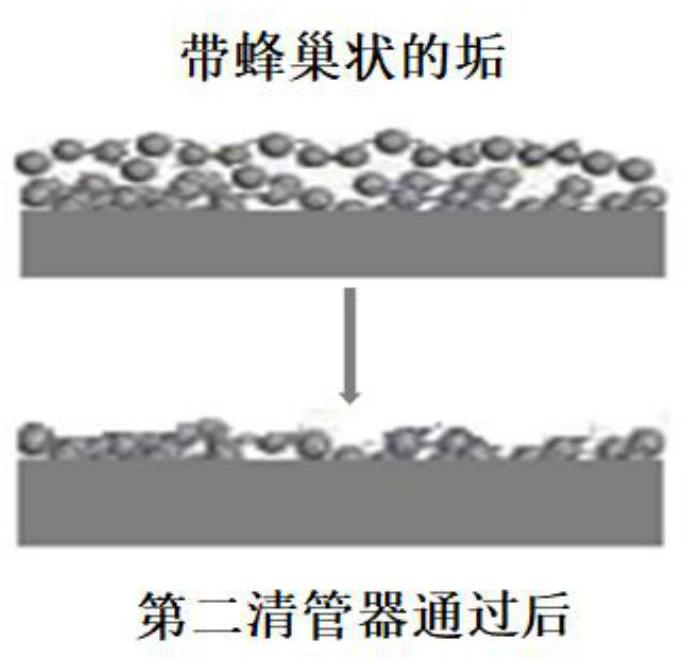

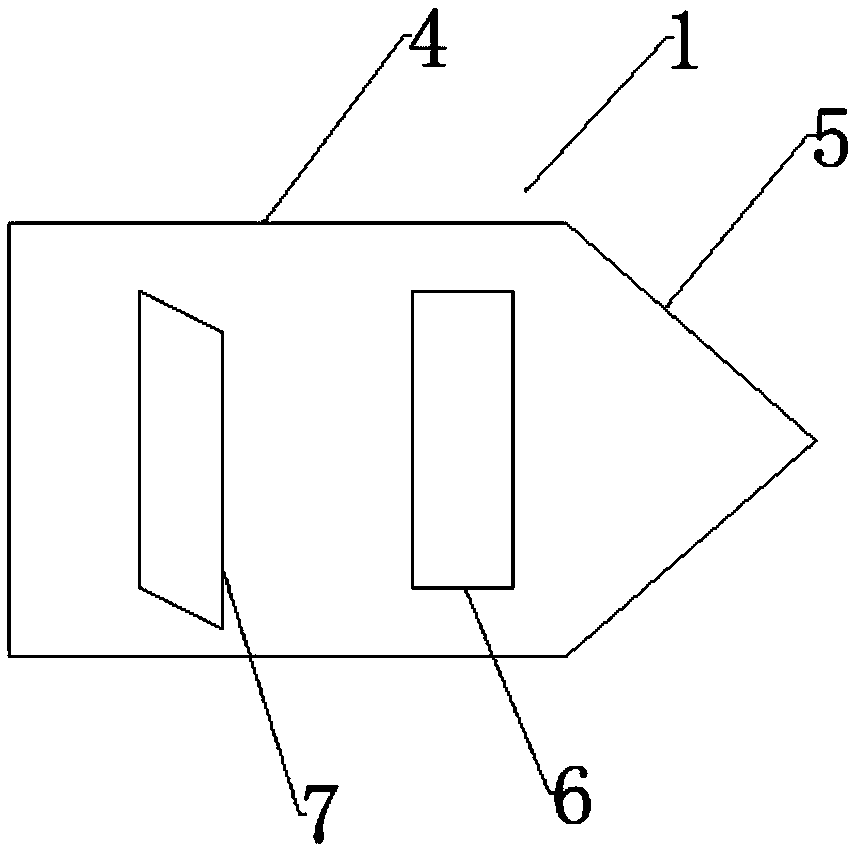

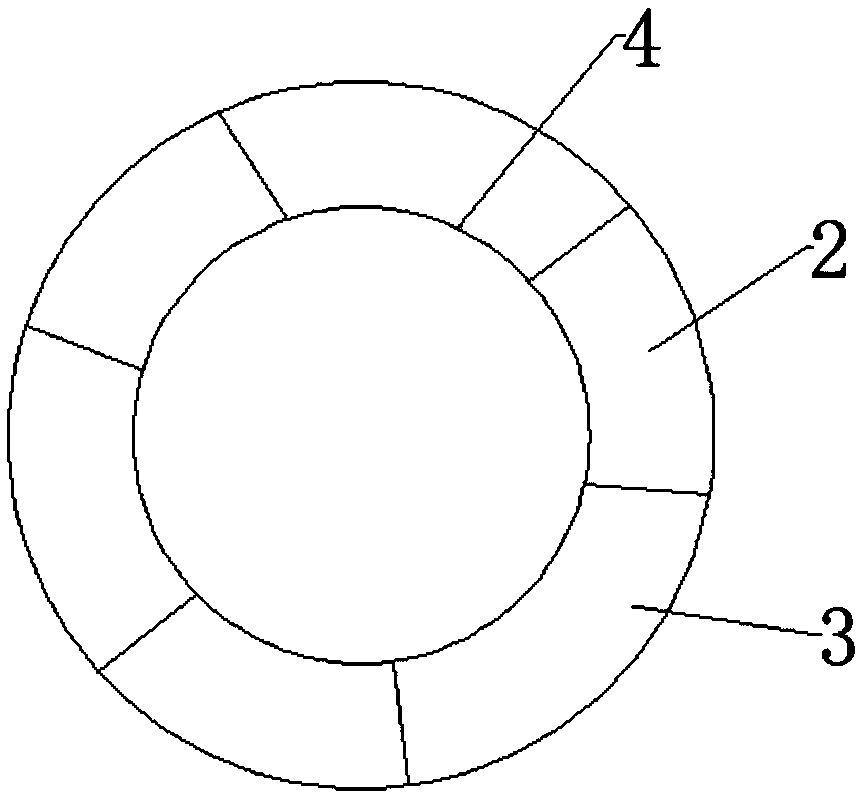

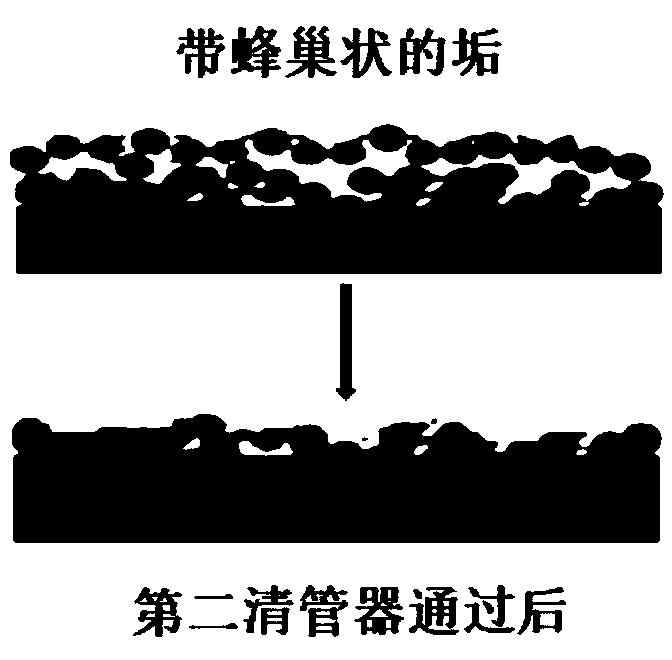

Composite descaling process of non-stop production of sea pipe throwing balls and descaling agent

ActiveCN109013585BEasy to bring outEnhance the effect of pigging and descalingHollow article cleaningProcess engineeringIndustrial engineering

The invention discloses a non-stop production subsea pipeline ball-throwing and anti-scaling agent compound descaling technology. A ball-throwing inlet is formed in the end, close to a crude oil inlet, on a subsea pipeline, and a ball-throwing outlet is formed in the end, close to a crude oil outlet, on the subsea pipeline; crude oil flows in a non-stop production mode from the crude oil inlet tothe crude oil outlet, a first pipe cleaning machine is put in first through the ball-throwing inlet, a second pipe cleaning pipe is put in after the first pipe cleaning machine flows out of the ball-throwing outlet, anti-scaling agents are put in through the crude oil inlet when the second pipe cleaning machine flows to a quarter of the length of the subsea pipeline, the second pipe cleaning machine is put in again when the anti-scaling agents are put in for 6-8 h, putting-in of the second pipe cleaning machine and the anti-scaling agents and the putting-in of the second pipe cleaning pipe again is a whole cleaning process, and the whole cleaning process is repeated until the last discharge of dirt weight is less than 3kg. The non-stop production subsea pipeline ball-throwing and anti-scaling agent compound descaling technology can effectively remove the dirt accumulated in the subsea pipeline, and can simultaneously carry out the subsea pipeline descaling operation without stopping production.

Owner:北京峦海阜程科技发展有限责任公司

Calcination-free industrial gypsum byproduct dry-mixed mortar activator

The invention discloses a calcination-free industrial gypsum byproduct dry-mixed mortar activator, which belongs to the field of dry-mixed mortar additives. The dry-mixed mortar activator is prepared with the following mixed materials in part by weight: 10 to 25 parts of calcium chloride, 3 to 8 parts of calcium nitrite, 5 to 15 parts of triethanolamine, 5 to 15 parts of triisopropanolamine, 30 to 50 parts of industrial sugar residue, 10 to 30 parts of water and a plurality of parts of mountain flour. Compared with the prior art, the dry-mixed mortar activator is characterized in that: the application range is wide, efflorescence cannot take place, and the strength of mortar at each age can be enhanced.

Owner:SHANDONG CHENGHUA BUILDING MATERIAL TECH

Non-stop production subsea pipeline ball-throwing and anti-scaling agent compound descaling technology

ActiveCN109013585AEasy to bring outEnhance the effect of pigging and descalingHollow article cleaningEngineeringPoint of entry

The invention discloses a non-stop production subsea pipeline ball-throwing and anti-scaling agent compound descaling technology. A ball-throwing inlet is formed in the end, close to a crude oil inlet, on a subsea pipeline, and a ball-throwing outlet is formed in the end, close to a crude oil outlet, on the subsea pipeline; crude oil flows in a non-stop production mode from the crude oil inlet tothe crude oil outlet, a first pipe cleaning machine is put in first through the ball-throwing inlet, a second pipe cleaning pipe is put in after the first pipe cleaning machine flows out of the ball-throwing outlet, anti-scaling agents are put in through the crude oil inlet when the second pipe cleaning machine flows to a quarter of the length of the subsea pipeline, the second pipe cleaning machine is put in again when the anti-scaling agents are put in for 6-8 h, putting-in of the second pipe cleaning machine and the anti-scaling agents and the putting-in of the second pipe cleaning pipe again is a whole cleaning process, and the whole cleaning process is repeated until the last discharge of dirt weight is less than 3kg. The non-stop production subsea pipeline ball-throwing and anti-scaling agent compound descaling technology can effectively remove the dirt accumulated in the subsea pipeline, and can simultaneously carry out the subsea pipeline descaling operation without stopping production.

Owner:北京峦海阜程科技发展有限责任公司

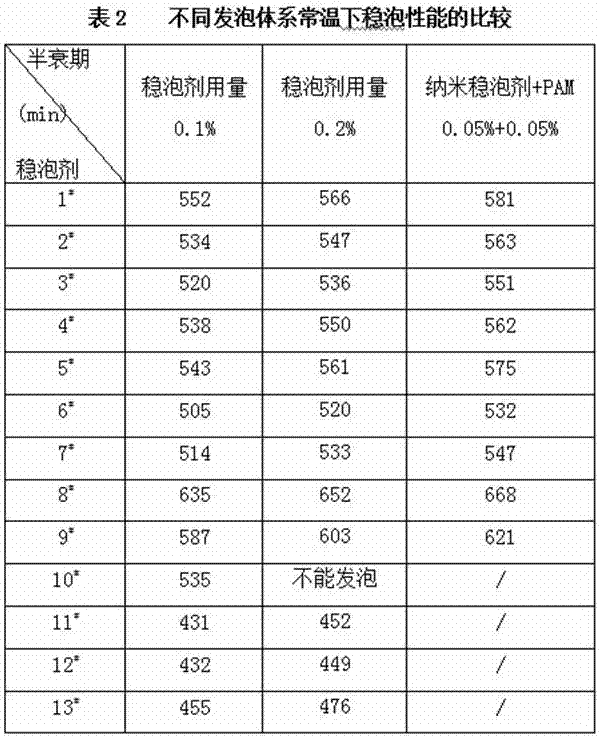

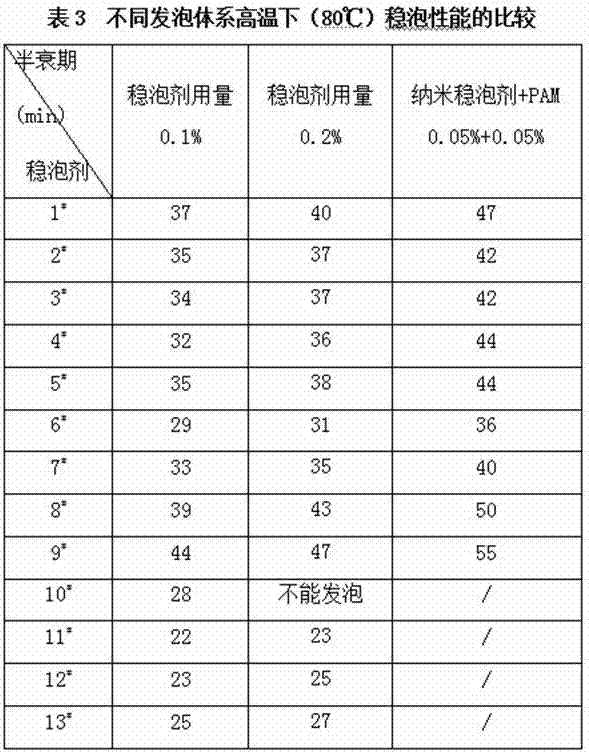

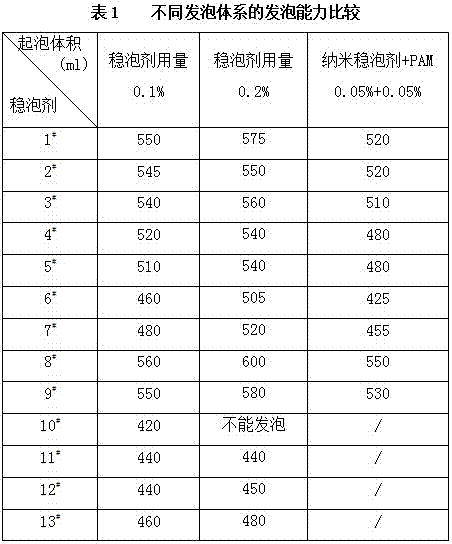

Modified nano silicon dioxide foam stabilizer and preparation method thereof

InactiveCN104152132BGood foam stabilitySimple preparation processSilicon organic compoundsDrilling compositionSulfite saltSilicon dioxide

The invention relates to a modified nano silicon dioxide (nano SiO2) foam stabilizer and a preparation method thereof. The nano foam stabilizer is prepared by carrying out hydrophilic modification on the nano SiO2. The preparation method comprises the following steps: activating the nano SiO2 by calcination, and uniformly dispersing in dimethylformamide (DMF), wherein the mass ratio of the nano SiO2 to the DMF is 1:10-1:30; adding maleic anhydride, wherein the mass ratio of the nano SiO2 to the maleic anhydride is 1:1-1:3; stirring at 60-80 DEG C to react for 3-5 hours, and adding a sodium sulfite saturated water solution, wherein the mole ratio of the maleic anhydride to the sodium sulfite is 1:1; and stirring to react for 1 hour, carrying out centrifugal dehydration, washing and drying. The nano foam stabilizer for enhancing foam stability of the foam flooding system has the characteristics of simple preparation technique, favorable foaming property and favorable foam stability, and has the characteristics of excellent foaming property and excellent foam stability especially when being compounded with the organic high-polymer foam stabilizer polyacrylamide.

Owner:SHANGHAI UNIV

A kind of natural fiber softener and preparation method thereof

ActiveCN103981721BEasy to dissolve and disperseWith maintenanceFibre treatmentPolyethylene glycolNatural fiber

Owner:佛山市魔晶科技发展有限公司

Preparation method of Chinese caterpillar fungus freeze-dried buccal tablet

ActiveCN102742838BEasy to carryEasy to dissolve and dispersePharmaceutical product form changeFood shapingFreeze-dryingAdditive ingredient

The invention belongs to the field of healthcare food, and particularly relates to a preparation method of a Chinese caterpillar fungus freeze-dried buccal tablet. The preparation method aims at maintaining the original unique flavor of stews to a certain extent, preserving the nutritional ingredients for a long time and making the taking convenient. The preparation method of Chinese caterpillar fungus freeze-dried buccal tablet comprises the steps of: a, stewing or boiling the prepared stew raw materials to obtain a cooked product containing solid matters and soup; b, homogenizing the cooked product; c, filling the homogenized cooked product into a bubble cap of a bubble cap tray; d, carrying out freezing and vacuum drying to obtain the tablet; and e, carrying out aluminum foil sealing on the vacuum frozen and dried plastic bubble cap. The Chinese caterpillar fungus freeze-dried buccal tablet prepared by the preparation method provided by the invention is convenient for carrying, convenient for eating and suitable for the senile patients, the critical patients, the dysphagia patients, the infants, the children and the like, and has a good market prospect.

Owner:QINGHAI SPRING MEDICINAL RESOURCES TECHNOLOGY CO LTD

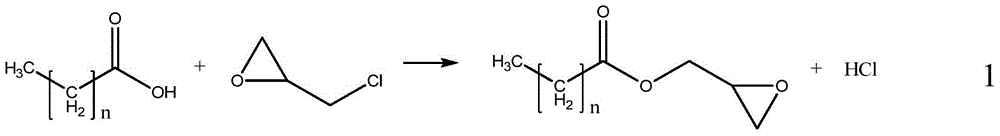

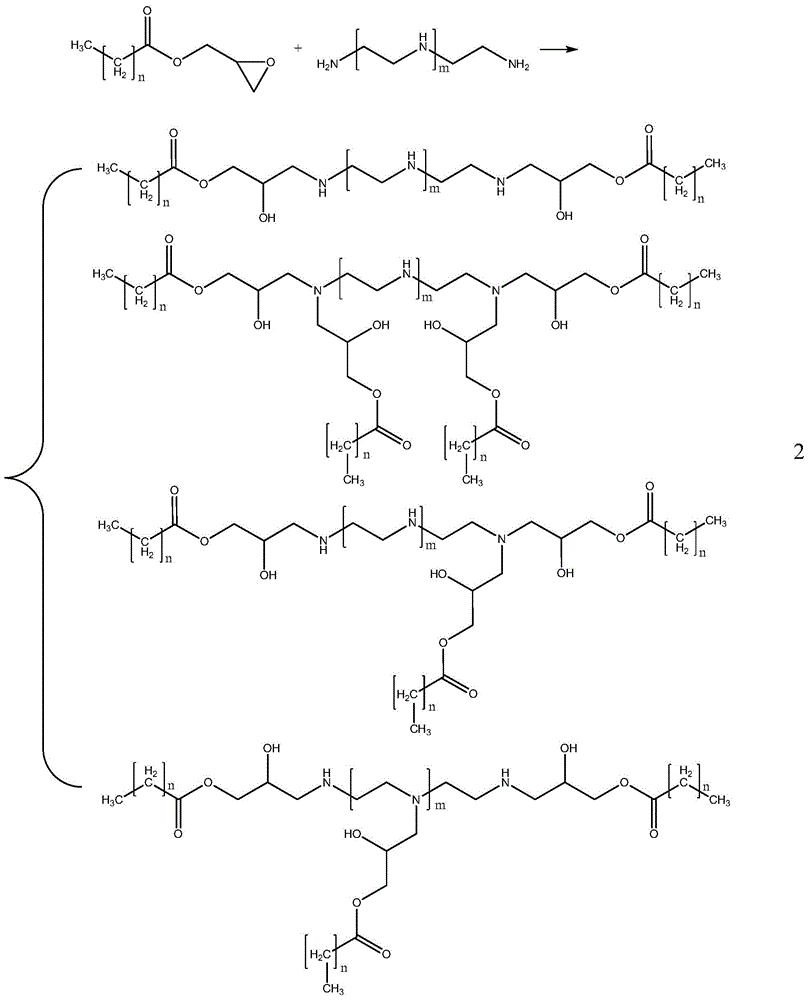

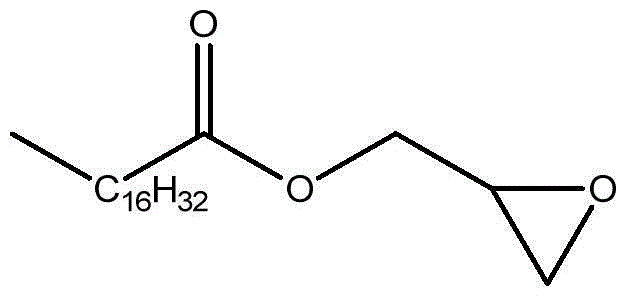

Long-chain alkyl polyamine series asphalt anti-stripping agent and preparation method thereof

The invention discloses a long-chain alkyl polyamine series asphalt anti-stripping agent. The raw materials of the anti-stripping agent include long-chain alkyl organic acids, epichlorohydrin and organic amines. Good compatibility, easy to dissolve and disperse in asphalt; moderate molecular weight, low viscosity, lower viscosity than asphalt, no migration and precipitation; mild synthesis conditions and other characteristics. In the invention, the raw materials are easily obtained, the synthesis reaction conditions are mild and easy to implement, and the structure and molecular weight of the product are easy to adjust to obtain excellent performance. It is prepared by first epoxidizing the organic acid with epichlorohydrin, and then carrying out the ring-opening reaction with the polyamine to covalently combine the product into a certain molecular weight anti-stripping agent molecule. The raw materials are easy to obtain, and the synthesis reaction conditions are mild and convenient. Easy to implement, easy to adjust product structure and molecular weight to obtain excellent performance.

Owner:云南交投集团公路建设有限公司 +1

Oil well plugging removal method

ActiveCN109057753BWon't hurtAvoid generatingCleaning apparatusDrilling compositionNitrogen gasThermal water

The invention discloses a blockage removal method for an oil well. An oil pipe is arranged in the oil well, and an annular space formed by the oil pipe and the well wall is internally provided with asleeve pipe. The method includes the following steps that a polymer neutral blockage removal agent is prepared; the prepared polymer neutral blockage removal agent is put into an inlet of the oil pipefor the first time, hot water with the temperature of 70 DEG C is added in an inlet of the sleeve pipe, the inlet of the oil pipe and the inlet of the sleeve pipe are closed, and the wellhead of theoil well is covered by insulating cotton; after being closed for 12 hours, the inlet of the oil pipe and the inlet of the sleeve pipe open again, the inlet of the sleeve pipe is then closed after hotwater with the temperature of 80 DEG C is added in the sleeve pipe for replacing original water, the prepared polymer neutral blockage removal agent is poured in the inlet of the oil pipe for the second time, and meanwhile mixed gas of carbon dioxide and nitrogen with the pressure of 2.0 MPa is continuously injected in the oil pipe. The method can effectively remove stratum blockage objects in theoil well, does not cause corrosion and damage to the stratum, equipment and pipelines, and also does not affect subsequent dehydration of crude oil.

Owner:北京峦海阜程科技发展有限责任公司

An ultrasonic washing barrel and washing ribbon production line

ActiveCN105862294BAchieve cleaningEasy to dissolve and disperseTextile treatment machine arrangementsVibration treatmentEngineeringProcess engineering

The invention discloses an ultrasonic washing tub and a washed woven belt production line. The ultrasonic washing tub comprises a washing tub body. A plurality of transmission rollers are arranged in the washing tub body in an upper row and a lower row. The lower row of transmission rollers are soaked in water, and the upper row of transmission rollers and the lower row of transmission rollers are arrayed in a staggered mode. Woven belts are sequentially wound around the transmission rollers from left to right, soaked in water, washed and then output. A least two ultrasonic generation devices are arranged on the inner wall of the washing tub. The top of each ultrasonic generation device is connected with a speed sensor. A heating device is arranged at the bottom of the washing tub body. The effect of washing away dirt and greasy dirt on surfaces of the woven belts is improved, and the woven belts are more thoroughly washed. In addition, according to the washed woven belt production line manufactured through the ultrasonic washing tubs, the multiple ultrasonic washing tubs work at the same time, and washing efficiency is improved.

Owner:OPPERMANN WEBBING KUSN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com