Mannich base acidizing corrosion inhibitor for organic acid system, and preparation method of Mannich base acidizing corrosion inhibitor

A technology of Mannich bases and acidifying corrosion inhibitors, applied in the direction of organic chemistry, etc., to achieve the effects of easy realization, improvement of adsorption firmness, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

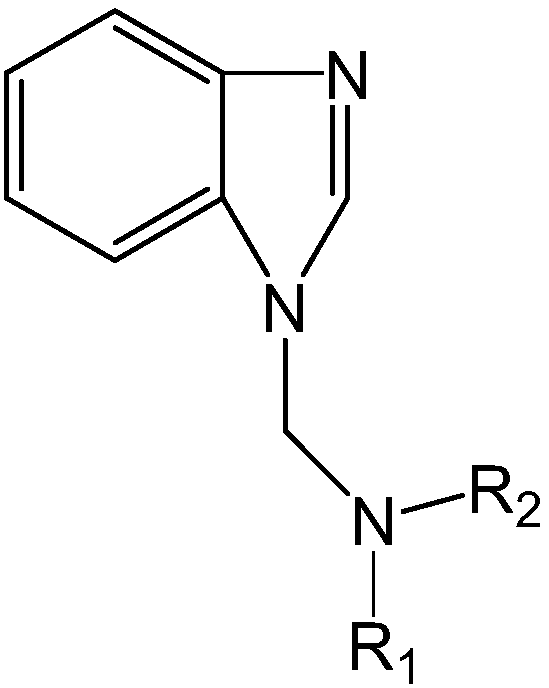

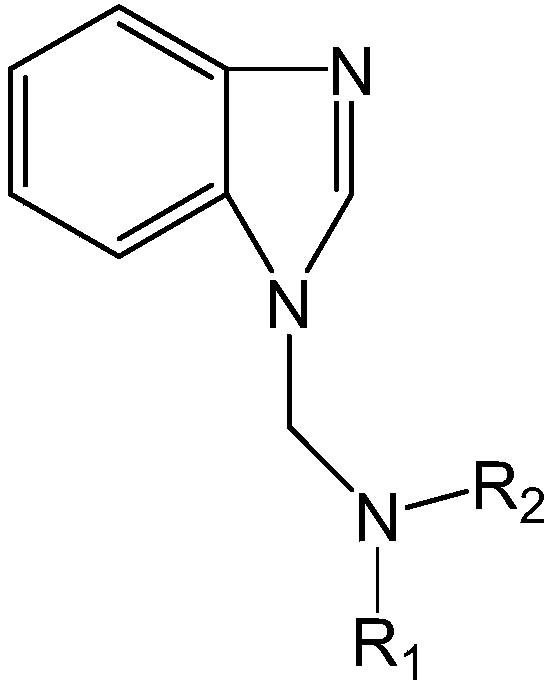

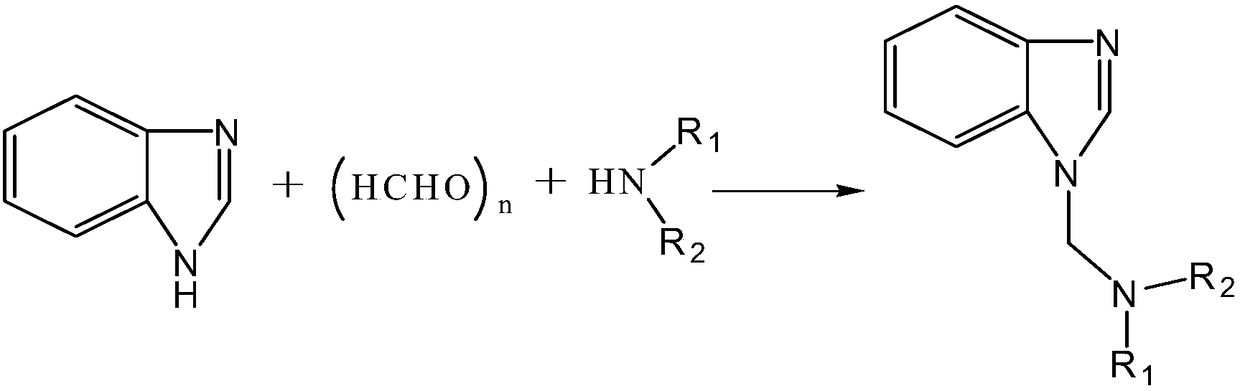

[0048] In this example, the preparation of the organic acid system Mannich base acidifying corrosion inhibitor is divided into two steps: the first step is the synthesis of the main agent, phenmimidazole Mannich base, and the second step is the preparation of the corrosion inhibitor.

[0049] Add benzoimazole, paraformaldehyde, and diethylamine into a three-necked flask at a molar ratio of 1:1.5:1, then add toluene and mix well, use hydrochloric acid with a mass concentration of 30% as a catalyst to adjust the pH value of the solution between 2 and 3 Between, be warming up to toluene reflux temperature again, heat preservation reaction 6 hours, obtain phentermine Mannich base;

[0050]Then, according to mass percentage, 25% of Mannich base of benzoimidazole, 15% of ammonium thiocyanate, 3% of propynyl alcohol, MOA-76% and 51% of dimethylformamide were uniformly mixed to obtain the organic acid system Mannich Nische base acidification corrosion inhibitor, code name TG203-1.

Embodiment 2

[0052] Add benzoimazole, paraformaldehyde, and dipropylamine into a three-necked flask at a molar ratio of 1:1.4:1, then add toluene and mix well, and use industrial acetic acid with a mass concentration of 75% as a catalyst to adjust the pH value of the solution between 2 and 3. Between, be warming up to toluene reflux temperature again, insulation reaction 6 hours, obtain phentermine Mannich base;

[0053] Then, in terms of mass percentage, 30% of phenylbenzimidazole Mannich base, 10% of ammonium thiocyanate, 3% of butynediol, 10% of MOA-9 and 47% of dimethylformamide were uniformly mixed to obtain an organic acid system Mannich base acidification corrosion inhibitor, code name TG203-2.

Embodiment 3

[0055] Add benzoimazole, paraformaldehyde, and dibutylamine into a three-necked flask at a molar ratio of 1:1.2:1, then add toluene and mix evenly, use hydrochloric acid with a mass concentration of 30% as a catalyst to adjust the pH value of the solution between 2 and 3 Between, be warming up to toluene reflux temperature again, insulation reaction 6 hours, obtain phentermine Mannich base;

[0056] Then, according to mass percentage, 20% of Mannich base of benzoimidazole, 15% of ammonium thiocyanate, 3% of butynediol, 95% of MOA-95% and 57% of isopropanol were uniformly mixed to obtain the organic acid system Mannich Greek alkali acidification corrosion inhibitor, code name TG203-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com