A pcb board multi-test process integrated test production line

A technology of PCB board and production line, which is applied in the field of integrated test production line of multiple test procedures of PCB board, which can solve the problems of easy occupation of factory space, increased operating costs of enterprises, and long delay time of PCB board, so as to achieve a clean and uncluttered workshop environment , cost and combination improvement, and the effect of free and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

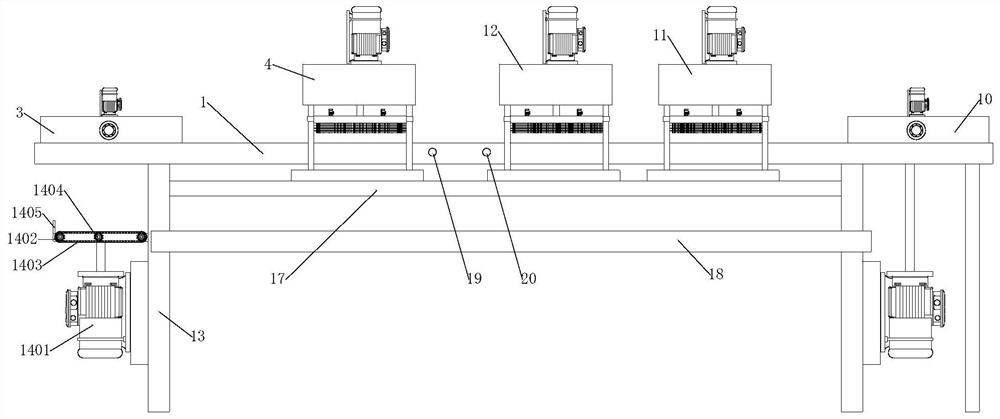

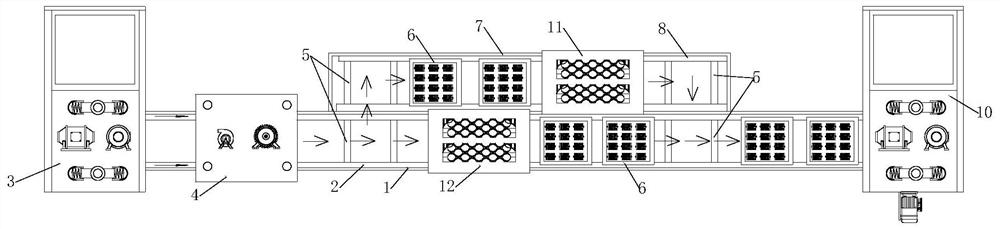

[0060] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , which is a schematic diagram of the entire structure of a PCB board integrated testing production line with multiple testing procedures.

[0061] Among them, see figure 1 and figure 2, an integrated testing production line for multiple testing processes of PCB boards, comprising a No. 1 assembly line rack 1, and a No. 2 assembly line rack 7 arranged side by side on the No. 1 assembly line rack 1, and the top of the No. 1 assembly line rack 1 The surface is a horizontal plane, the top middle of the No. 1 assembly line rack 1 is an empty structure, the front and rear sides of the top of the No. 1 assembly line rack 1 are symmetrically provided with a No. 1 conveyor belt 2, and the top of the No. 1 assembly line rack 1 is placed with a pallet 6. The top of the pallet 6 is equidistantly arranged with several PCB boards in a matrix. The pallet 6 is placed on the No. 1 conveyor belt 2 on the front and rear...

Embodiment 2

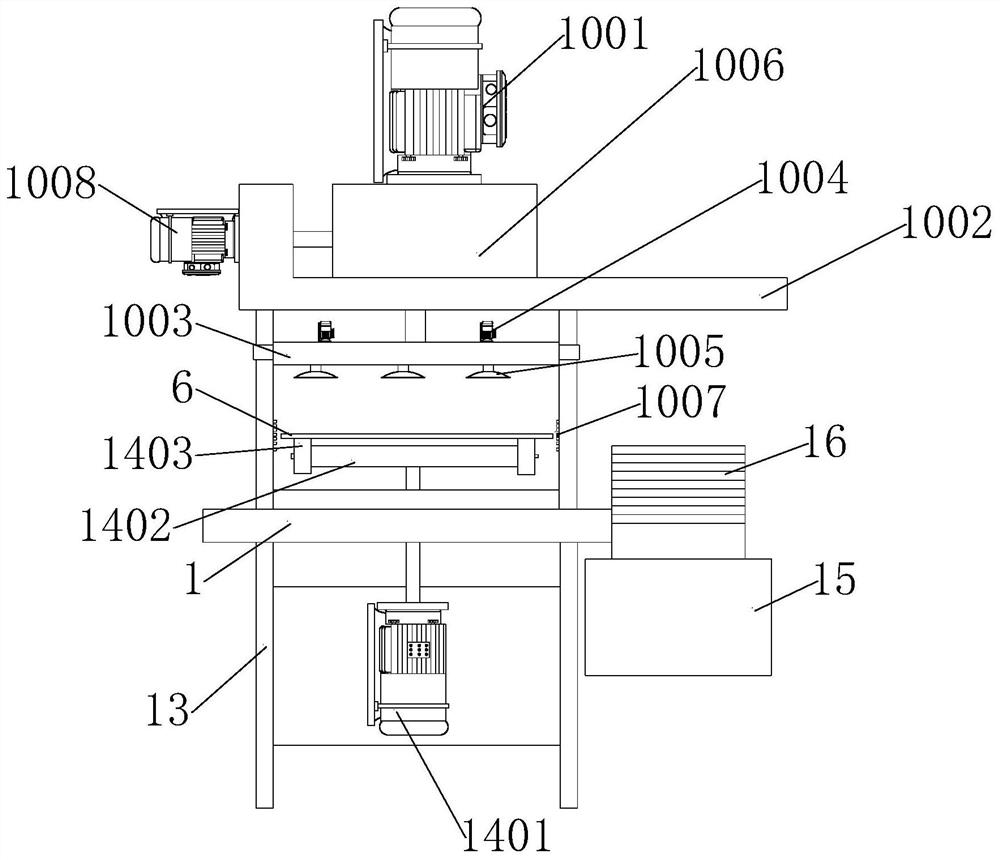

[0095] see figure 1 , figure 2 as well as Figure 6-Figure 14 , this embodiment and the above-mentioned embodiment 1 have the same points, the same points will not be repeated in this embodiment, and the specific differences are:

[0096] The PCB board non-contact cleaning device includes a No. 1 assembly line rack 1, and a No. 2 assembly line rack 7 arranged in parallel on the side of the No. 1 assembly line rack 1. The top surface of the No. 1 assembly line rack 1 is a horizontal plane, and the No. 1 assembly line rack 1 is horizontal. The middle of the top of the assembly line rack 1 is an empty structure. The front and rear sides of the top of the No. 1 assembly line rack 1 are symmetrically provided with a No. 1 conveyor belt 2. A support plate 6 is placed at the top of the No. 1 assembly line rack 1, and the top of the support plate 6 is equally spaced. Several PCB boards are arranged in a matrix, and the pallet 6 is placed on the No. 1 conveyor belt 2 on the front an...

Embodiment 3

[0124] see figure 1 , figure 2 as well as Figure 15-Figure 23 , this embodiment and the above-mentioned embodiment 1 have the same points, the same points will not be repeated in this embodiment, and the specific differences are:

[0125] The multiple groups of PCB board floating testing devices include a No. 1 assembly line rack 1, and a No. 2 assembly line rack 7 arranged in parallel on the side of the No. 1 assembly line rack 1. The top surface of the No. 1 assembly line rack 1 is a horizontal plane, and a The top and middle of the No. 1 assembly line rack 1 is an empty structure. The No. 1 conveyor belt 2 is symmetrically arranged on the front and rear sides of the top of the No. 1 assembly line rack 1. The top of the No. 1 assembly line rack 1 is placed with a pallet 6, the top of the pallet 6, etc. There are several PCB boards arranged in a matrix with a spacing. The pallet 6 is placed on the No. 1 conveyor belt 2 on the front and rear sides of the top of the No. 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com