Modified nano silicon dioxide foam stabilizer and preparation method thereof

A nano-silica, foam stabilizer technology, applied in chemical instruments and methods, silicon organic compounds, drilling compositions, etc., can solve the problem of poor temperature and salt resistance and shear resistance of polymers, foaming ability drop and other problems, to achieve the effect of good stability, uniform and fine foam, easy to dissolve and disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

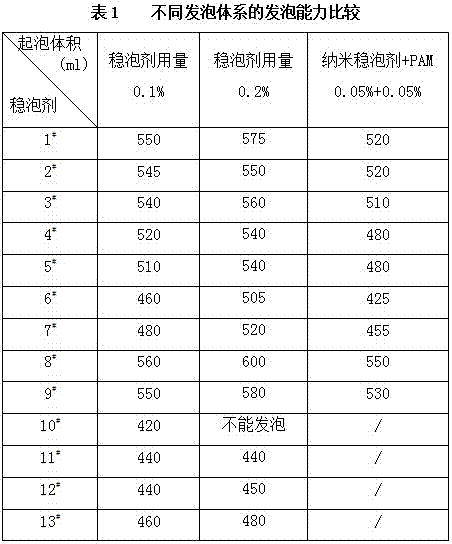

[0025] Example 1: Weighing 1g of activated nano-SiO with a particle size of 100nm 2 , put into the Erlenmeyer flask, add 20g of DMF after dehydration treatment, fully stir evenly, and ultrasonically disperse for 15min; weigh 3g of maleic anhydride, add 5g of DMF after dehydration treatment to dissolve, add into the Erlenmeyer flask, and mix evenly; place the three-necked flask On a magnetic stirrer, the reaction was stirred at a constant temperature of 60° C. for 5 h. After the reaction was completed, 3.85 g of sodium sulfite was weighed to make a saturated aqueous solution, which was added dropwise into the reaction system, and stirred for 1 h. Gained reaction product is centrifuged and washed, and dried to obtain a nano-foam stabilizer, which is denoted as 1 # .

Embodiment 2

[0026] Embodiment 2: Weighing 1g of nano-SiO with a particle size of 100nm after activation treatment 2 , put into the Erlenmeyer flask, add 10g of DMF after dehydration treatment, fully stir evenly, and ultrasonically disperse for 15min; weigh 3g of maleic anhydride, add 5g of DMF after dehydration treatment to dissolve, add into the Erlenmeyer flask, and mix evenly; place the three-necked flask On a magnetic stirrer, the reaction was stirred at a constant temperature of 70° C. for 3 h. After the reaction was completed, 3.85 g of sodium sulfite was weighed to make a saturated aqueous solution, which was added dropwise into the reaction system, and stirred for 1 h. The resulting reaction product was centrifuged, washed, dried, and recorded as 2 # .

Embodiment 3

[0027] Example 3: Weighing 1 g of activated nano-SiO with a particle size of 100 nm 2 , put into the Erlenmeyer flask, add 10g of DMF after dehydration treatment, fully stir evenly, and ultrasonically disperse for 15min; weigh 3g of maleic anhydride, add 5g of DMF after dehydration treatment to dissolve, add into the Erlenmeyer flask, and mix evenly; place the three-necked flask On a magnetic stirrer, the reaction was stirred at a constant temperature of 80° C. for 5 h. After the reaction, 3.85g of sodium sulfite was weighed to form a saturated aqueous solution, which was dropped into the reaction system and stirred for 1 hour. The resulting reaction product was centrifuged, washed, dried, and recorded as 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com