Preparation method of acrylic acid modified waterborne polyurethane dispersion liquid used for metallic paint

A technology of water-based polyurethane and metal coatings, applied in the direction of coating, etc., can solve problems such as delamination, poor copolymerization of acrylic acid and water-based polyurethane dispersion, and poor hardness of the salt-spray resistant coating film of the copolymerization product, etc., to achieve Excellent acid resistance, stable performance, good hardness and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

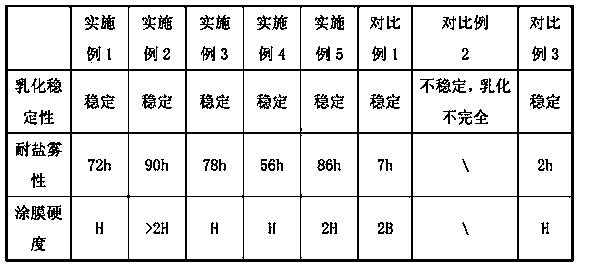

Examples

Embodiment 1

[0023] Example 1: 0.4 mol of isophorone diisocyanate was added dropwise to a mixed solution of 0.05 mol of polyglycerol and 0.05 mol of polycaprolactone diol, 0.3 g of stannous octoate was added as a catalyst, and reacted at 85° C. for 2 h to obtain White viscous polyurethane prepolymer. Add 0.1mol ethylene glycol, 0.02mol trimethylolpropane and 0.08mol dimethylolpropionic acid to the prepolymer, and after chain extension reaction at 85°C for 0.5h, add 0.18mol hydroxyethyl acrylate to react for 0.5h , add 0.08mol triethylamine to neutralize, add 350ml deionized water to prepare aqueous polyurethane dispersion. Prepare a mixture of 0.4mol methyl methacrylate, 0.3mol n-butyl acrylate, 0.1mol acrylic acid, and 2.0g oleic acid diethanolamide, prepare 1g of ammonium persulfate in water, and pour it into the aqueous polyurethane dispersion at 90°C The mixed solution and ammonium persulfate aqueous solution were added dropwise, and after the dropwise addition, the temperature was ra...

Embodiment 2

[0024] Example 2: 0.4 mol of isophorone diisocyanate was added dropwise to a mixed solution of 0.05 mol polytetrahydrofuran diol and 0.05 mol polycarbonate diol, 0.3 g of stannous octoate was added as a catalyst, and reacted at 80° C. for 3 h to obtain White viscous polyurethane prepolymer. Add 0.15mol 1,6-hexanediol and 0.08mol dimethylol butyric acid to the prepolymer, after chain extension reaction at 80°C for 1h, add 0.14mol hydroxyethyl acrylate to react for 0.5h, add 0.08mol triethylamine And, add 400ml of deionized water to prepare an aqueous polyurethane dispersion. Prepare a mixed solution of 0.6mol methyl methacrylate, 0.4mol n-butyl acrylate, 0.1mol acrylic acid, and 2.0g polyether phosphate salt, prepare an aqueous solution of 1.2g ammonium persulfate, and pour it into the aqueous polyurethane dispersion at 80°C At the same time, the mixed solution and the ammonium persulfate aqueous solution were added dropwise, and after the dropwise addition was completed, the ...

Embodiment 3

[0025] Example 3: 0.4 mol of isophorone diisocyanate was added dropwise to a mixture of 0.08 mol of polyglycerol and 0.03 mol of polycarbonate diol, 0.3 g of stannous octoate was added as a catalyst, and reacted at 95° C. for 1 h to obtain a white Viscous polyurethane prepolymer. Add 0.1mol ethylene glycol, 0.02mol trimethylolpropane and 0.09mol dimethylolpropionic acid to the prepolymer, after chain extension reaction at 82°C for 0.6h, add 0.14mol hydroxyethyl acrylate to react for 0.5h, Add 0.1 mol of triethylamine for neutralization, and add 450 ml of deionized water to prepare an aqueous polyurethane dispersion. Prepare a mixed solution of 0.5mol methyl methacrylate, 0.8mol n-butyl acrylate, 0.2mol acrylic acid, and 4.0g polyether phosphate salt, prepare an aqueous solution of 1.2g ammonium persulfate, and pour it into the aqueous polyurethane dispersion at 90°C At the same time, the mixed solution and the ammonium persulfate aqueous solution were added dropwise, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com