Clothes softener

A technology of fabric softener and thickener, which is applied in the field of fabric softener and can solve problems such as poor fabric feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

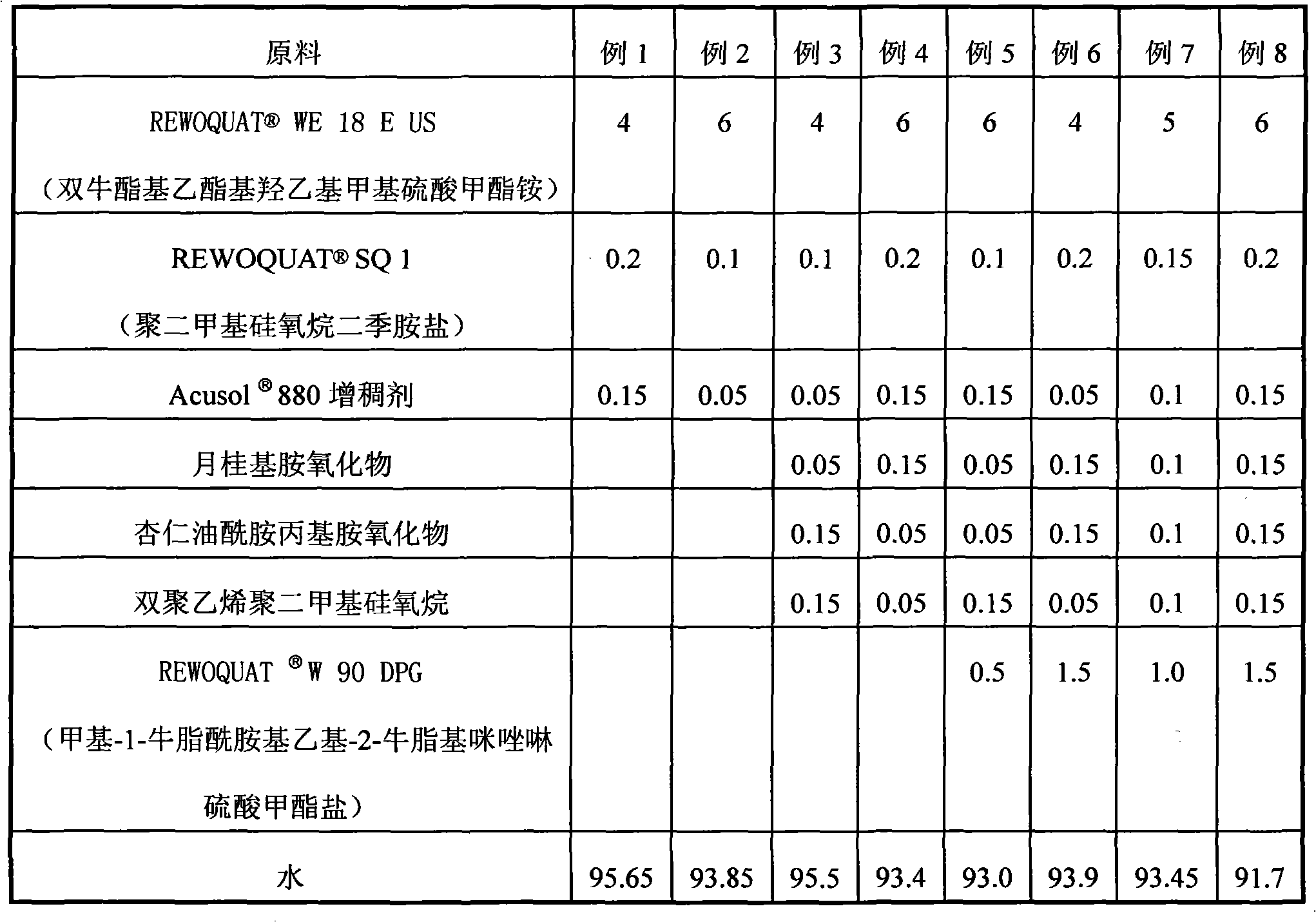

[0058] Weigh each raw material sequentially according to the data corresponding to Example 1 in Table 1.

[0059] Heat the water to about 30°C, slowly add the thickener, stir for 10-20 minutes, slowly add bis-tallow ethyl ethyl hydroxyethyl ammonium methyl sulfate and polydimethylsiloxane diquaternary ammonium salt, The fabric softener of the present invention can be prepared by continuously stirring for 15-25 minutes.

[0060] Table 1: Formulation of fabric softener Unit: kg

[0061]

Embodiment 2

[0063] Weigh each raw material sequentially according to the data corresponding to Example 2 in Table 1. According to the method described in Example 1, the fabric softener of the present invention was prepared.

[0064] Further, in the above-mentioned prepared fabric softener, add 0.3 kg MHN 4000 packaged essence and 0.2 kg of common essence are stirred and mixed evenly to obtain the essence-containing fabric softener of the present invention. said MHN 4000 wrapped flavor has the same aroma as ordinary flavor.

Embodiment 3

[0066] Weigh each raw material sequentially according to the data corresponding to example 3 in Table 1.

[0067] Heat the water to about 30°C, slowly add the thickener, stir for 10-20 minutes, slowly add bis-tallow ethyl ethyl hydroxyethyl ammonium methyl sulfate, polydimethylsiloxane diquaternary ammonium salt, Laurylamine oxide, almond oil amidopropylamine oxide and double polyethylene polydimethylsiloxane are continuously stirred for 15 to 25 minutes to prepare the fabric softener of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com