High-overload transformer

A transformer and high overload technology, applied in the direction of transformer/inductor cooling, transformer/inductor core, transformer/inductor components, etc., can solve poor heat dissipation effect, distribution transformer burnout, large temperature rise calculation deviation, etc. Problems, to achieve the effect of reducing the demand for material quantity, reducing no-load loss, and reducing cycle speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

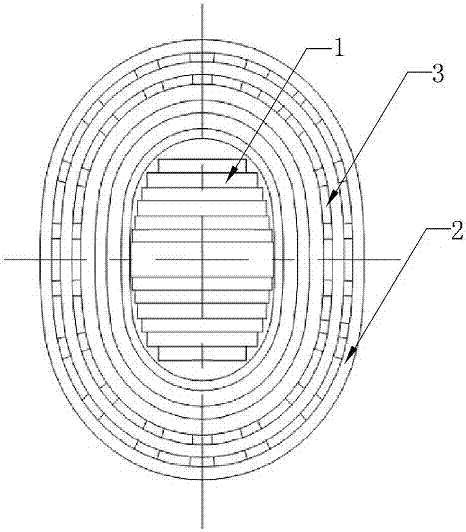

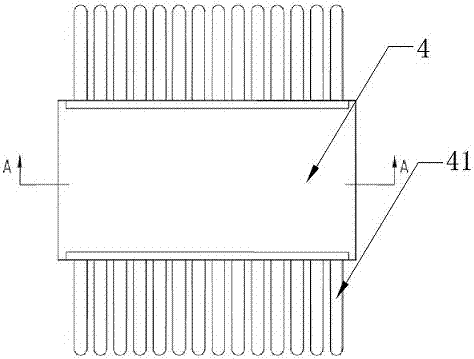

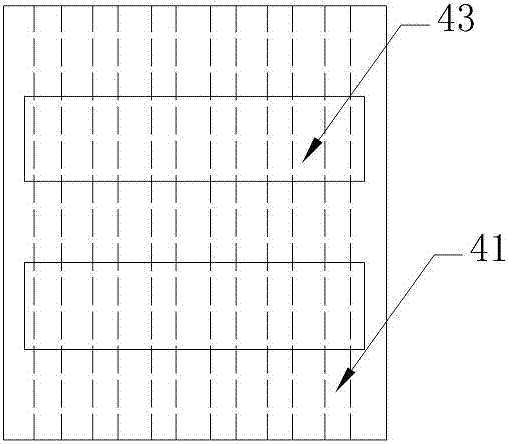

[0021] High overload transformer, including iron core 1, high voltage winding 2, low voltage winding 3 and oil tank 4;

[0022] Such as figure 1 As shown, the iron core 1 is an elliptical structure formed by lamination of high magnetic permeability silicon steel or amorphous alloy, and the magnetic flux density of the iron core 1 is 1.65T; in this embodiment, the material of amorphous alloy is selected, which has low eddy current loss, Small no-load loss and other characteristics, suitable for the operating conditions of rural power grids;

[0023] The low-voltage winding 3 is wound with four single 4.5X8.75 paper-wrapped copper flat wires, the number of turns is 39, and the current density of the low-voltage winding 3 is less than 3.5A / mm2;

[0024] The high-voltage winding 2 is an elliptical multi-layer cylindrical structure, there are no sharp corners and straight parts, the number of turns is 1024, and the amplitude margin is reduced by 1% to 2%;

[0025] The high-voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic flux density | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

| Magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com