An ultrasonic washing barrel and washing ribbon production line

A technology of washing buckets and ultrasonic waves is applied in the field of webbing manufacturing, which can solve the problems that the surface of webbing is dirty and oily, and the cleaning effect needs to be improved, etc., and achieves the effect of cleaning and thorough cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

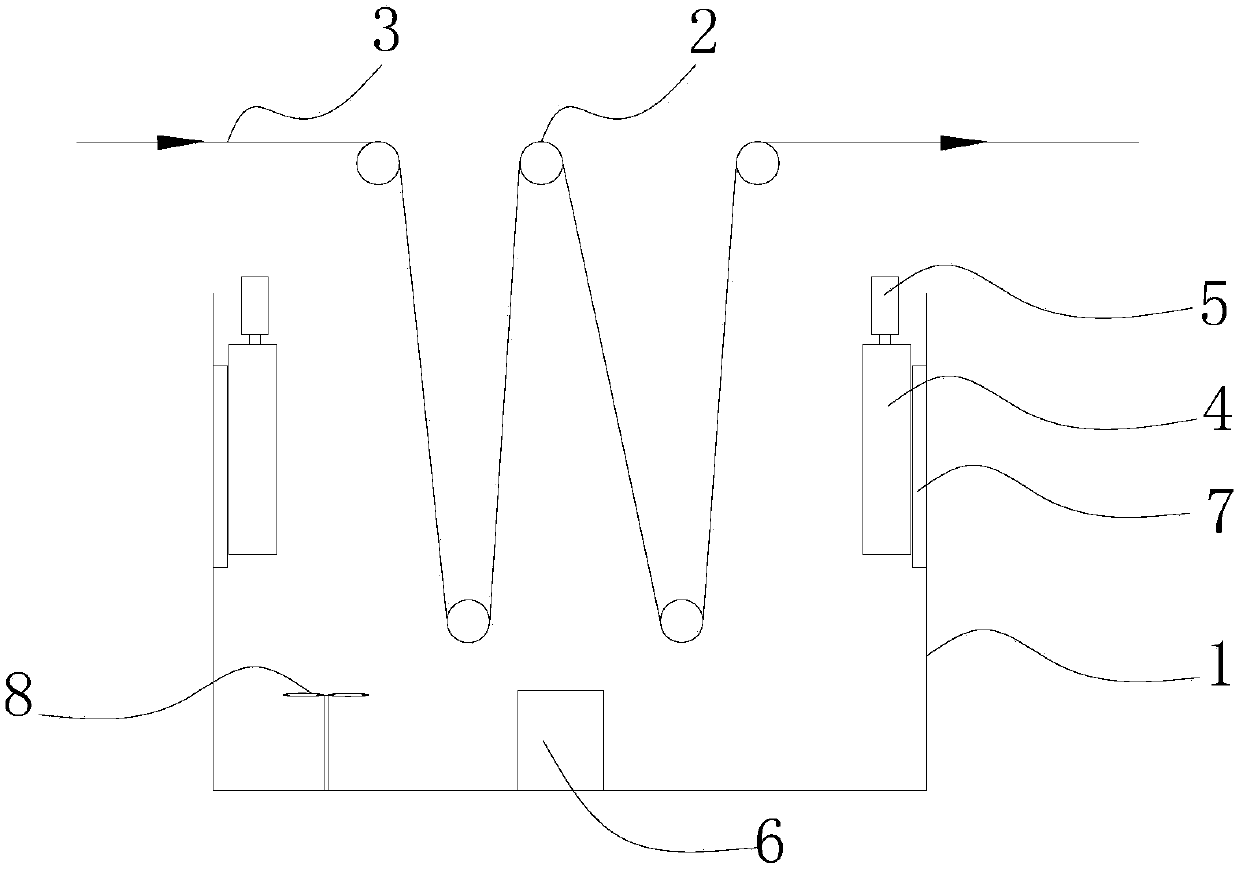

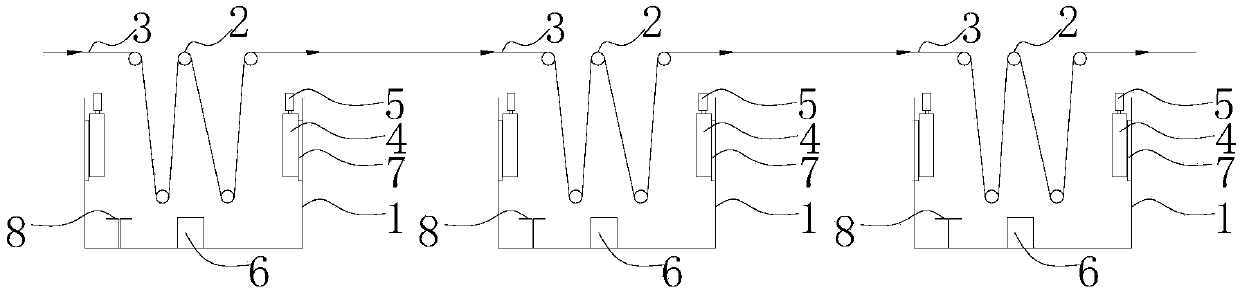

[0021] Combine below figure 1 , figure 2 The technical solutions of the present invention are further described through specific implementation methods.

[0022] First of all, it should be noted that the terms "top", "bottom", "upper", "lower", "left", and "right" used in the present invention refer to the page view and should not be understood as protection Scope limitation.

[0023] Such as figure 1 As shown, a kind of ultrasonic washing bucket of the present invention comprises washing bucket 1, and the inside of washing bucket 1 is provided with several transmission rollers 2, and transmission roller 2 is arranged in a row up and down, and the transmission roller 2 of lower row is immersed in water, and the transmission roller 2 of upper row The driving roller 2 and the driving roller 2 in the lower row are arranged alternately, and the webbing 3 bypasses the driving roller 2 from left to right, immerses in water, and then outputs after cleaning, so that the webbing 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com