Destaticizer, preparation method and textile materials containing destaticizer

A textile material and antistatic technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of limited electrostatic effect and poor durability of antistatic agents, achieve suppleness and maintenance, good antistatic performance, and easy to dissolve and disperse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

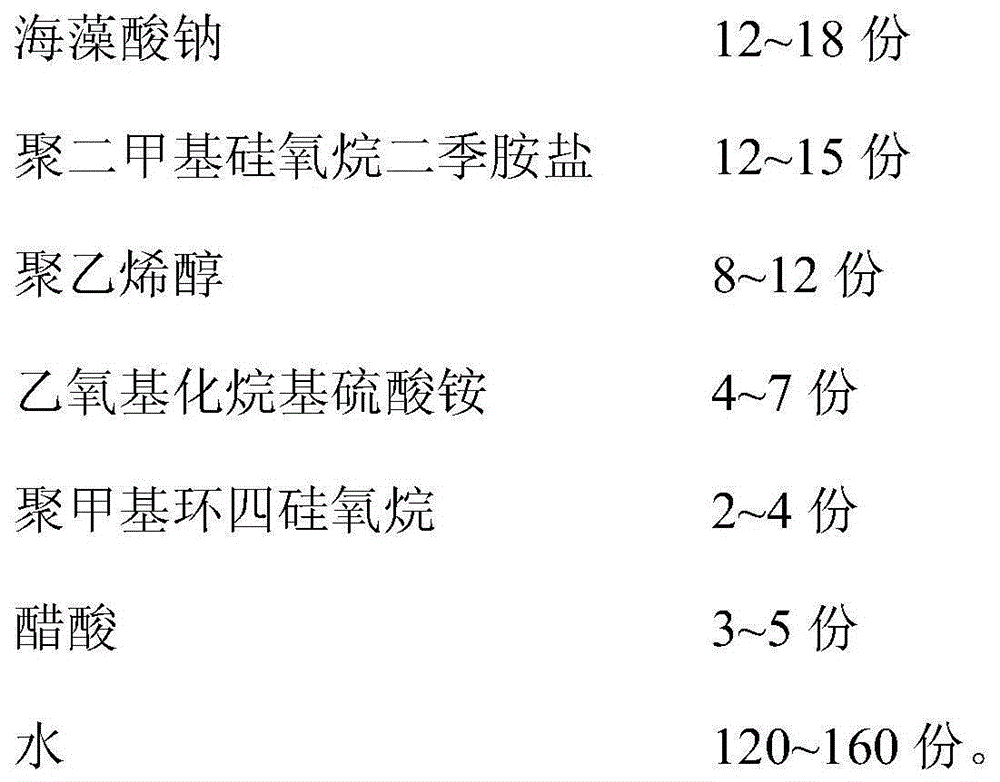

[0026] A static remover for textile materials, which is mainly prepared from the following raw materials in parts by weight:

[0027]

[0028]

[0029] The data molecular weight of the polyvinyl alcohol is 3000-4000.

[0030] The preparation method for the antistatic agent of textile material as above, described method comprises the following steps:

[0031] Mix water, sodium alginate, polydimethylsiloxane diquaternary ammonium salt, polyvinyl alcohol, and ethoxylated alkylammonium sulfate, and stir evenly at 55-70°C; then, slowly add acetic acid, and heat Under certain conditions, polymethylcyclotetrasiloxane is added and stirred evenly to obtain a static remover for textile materials.

[0032] After applying the above-mentioned antistatic agent to wool fiber, after drying, the specific situation of the electrostatic half-life of wool textiles is shown in Table 1.

Embodiment 2

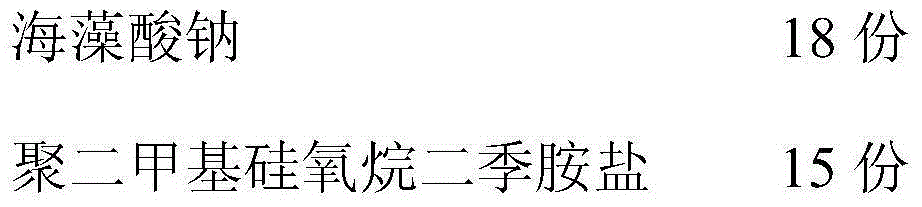

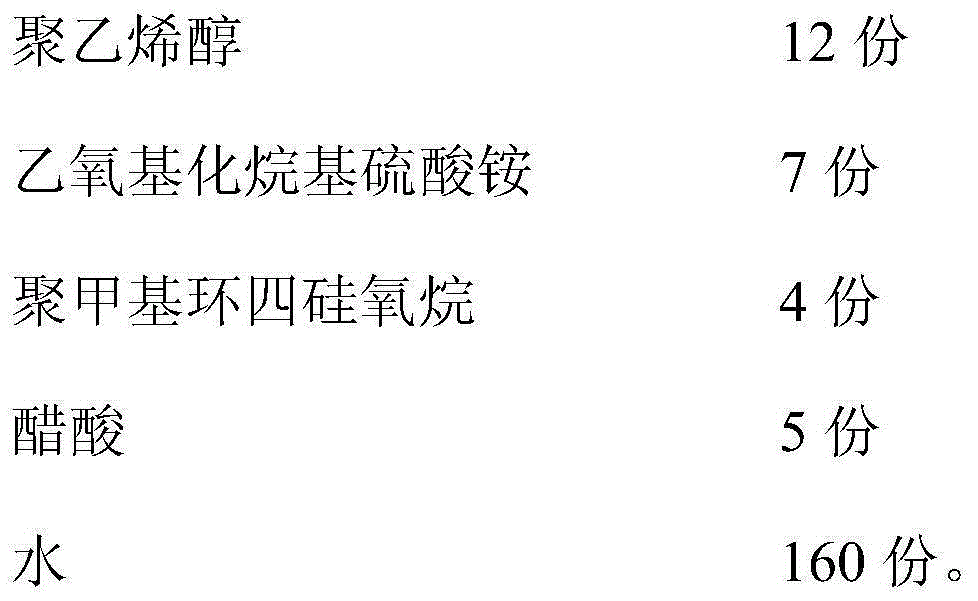

[0034] A static remover for textile materials, which is mainly prepared from the following raw materials in parts by weight:

[0035]

[0036] The data molecular weight of the polyvinyl alcohol is 3000-4000.

[0037] The preparation method for the antistatic agent of textile material as above, described method comprises the following steps:

[0038] Mix water, sodium alginate, polydimethylsiloxane diquaternary ammonium salt, polyvinyl alcohol, and ethoxylated alkylammonium sulfate, and stir evenly at 55-70°C; then, slowly add acetic acid, and heat Under certain conditions, polymethylcyclotetrasiloxane is added and stirred evenly to obtain a static remover for textile materials.

[0039] After applying the above-mentioned antistatic agent to wool fiber, after drying, the specific situation of the electrostatic half-life of wool textiles is shown in Table 1.

Embodiment 3

[0041] A static remover for textile materials, which is mainly prepared from the following raw materials in parts by weight:

[0042]

[0043] The data molecular weight of the polyvinyl alcohol is 3000-4000.

[0044] The preparation method for the antistatic agent of textile material as above, described method comprises the following steps:

[0045] Mix water, sodium alginate, polydimethylsiloxane diquaternary ammonium salt, polyvinyl alcohol, and ethoxylated alkylammonium sulfate, and stir evenly at 55-70°C; then, slowly add acetic acid, and heat Under certain conditions, polymethylcyclotetrasiloxane is added and stirred evenly to obtain a static remover for textile materials.

[0046] After applying the above-mentioned antistatic agent to wool fiber, after drying, the specific situation of the electrostatic half-life of wool textiles is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com