A kind of natural fiber softener and preparation method thereof

A natural fiber, softener technology, used in fiber processing, textiles and papermaking, etc., can solve problems such as poor biodegradability and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

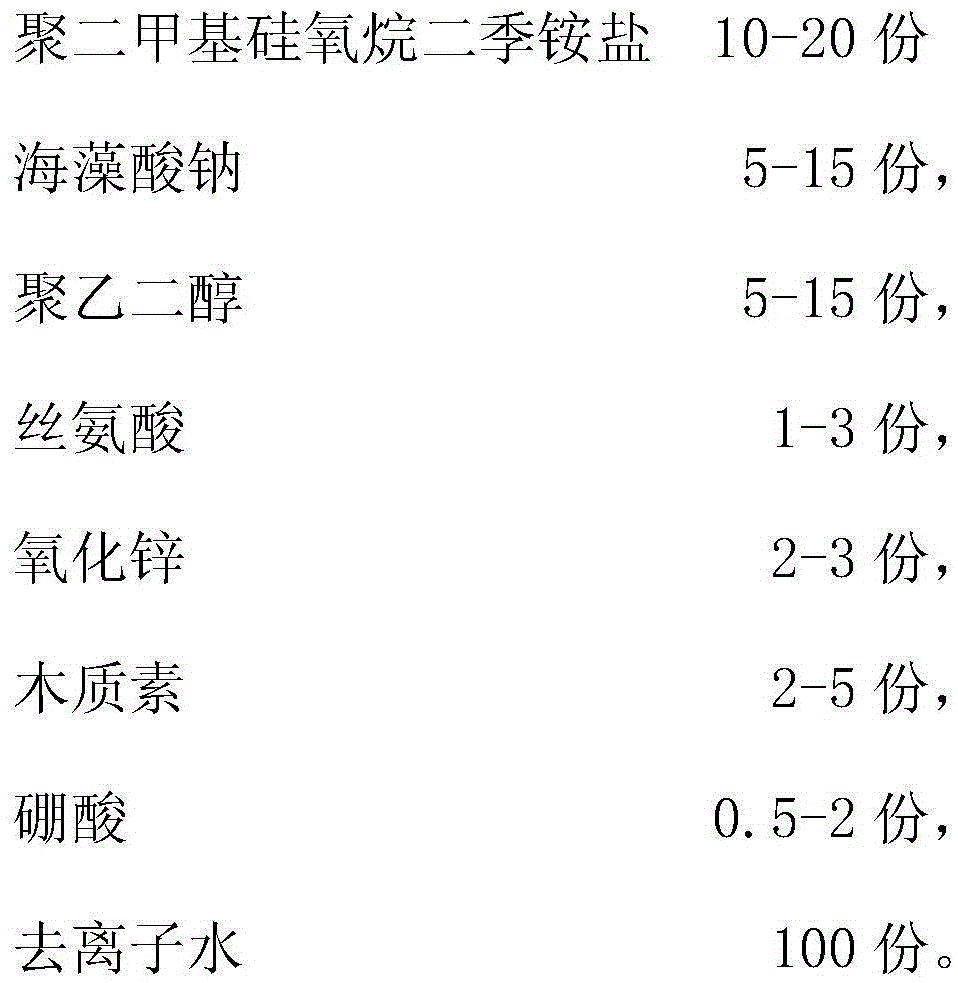

Method used

Image

Examples

Embodiment 1

[0018] (1) In 30kg deionized water, adding sodium alginate 5kg, relative molecular weight is 2.5kg of polyethylene glycol of 400, relative molecular weight is 2.5kg of polyethylene glycol of 800, serine 1kg, zinc oxide 2kg, lignin 3kg and polyethylene glycol Dimethylsiloxane diquaternary ammonium salt 10kg, at 45°C, the stirring rate is 1200 rpm, and the stirring time is 1 hour;

[0019] (2) Add 70kg of deionized water to the solution of step (1), slowly add 2kg of boric acid, stir evenly, and obtain the natural fiber softener.

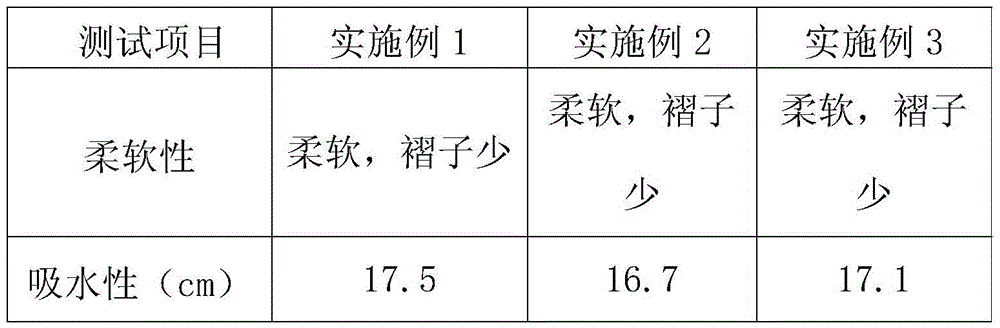

[0020] The performance test results of the prepared natural fiber softener are shown in Table 1.

Embodiment 2

[0022] (1) in 30kg deionized water, add sodium alginate 15kg, relative molecular weight is 400 polyethylene glycol 7.5kg, relative molecular weight is 800 polyethylene glycol 7.5kg, serine 3kg, zinc oxide 3kg, lignin 2kg and polyethylene glycol Dimethylsiloxane diquaternary ammonium salt 20kg, at 50°C, the stirring rate is 1200 rpm, and the stirring time is 3 hours;

[0023] (2) Add 70 kg of deionized water to the solution of step (1), slowly add 0.5 kg of boric acid, stir evenly, and obtain a natural fiber softener.

[0024] The performance test results of the prepared natural fiber softener are shown in Table 1.

Embodiment 3

[0026] (1) In 30kg of deionized water, add 10kg of sodium alginate, 5kg of polyethylene glycol with a relative molecular weight of 400, 5kg of polyethylene glycol with a relative molecular weight of 800, 2kg of serine, 2kg of zinc oxide, 5kg of lignin and polyethylene glycol 15kg of siloxane diquaternary ammonium salt, at 40°C, the stirring rate was 1200 rpm, and the stirring time was 2 hours;

[0027] (2) Add 70 kg of deionized water to the solution of step (1), slowly add 1 kg of boric acid, stir evenly, and obtain a natural fiber softener.

[0028] The performance test results of the prepared natural fiber softener are shown in Table 1.

[0029] Water absorption test method: Under the conditions of 25°C and 40% humidity, the lower end of a cotton towel (2.5cm×25cm) is immersed in water at 25°C, and the height of the water rising after 15 minutes is measured.

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com