Double-component catalyst for cyanate solidification reaction and its preparing process

A curing reaction and cyanate ester technology, applied in the chemical industry, can solve the problems of limitation, small dosage, difficult to control the dosage, etc., and achieve the effects of easy weighing, high catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

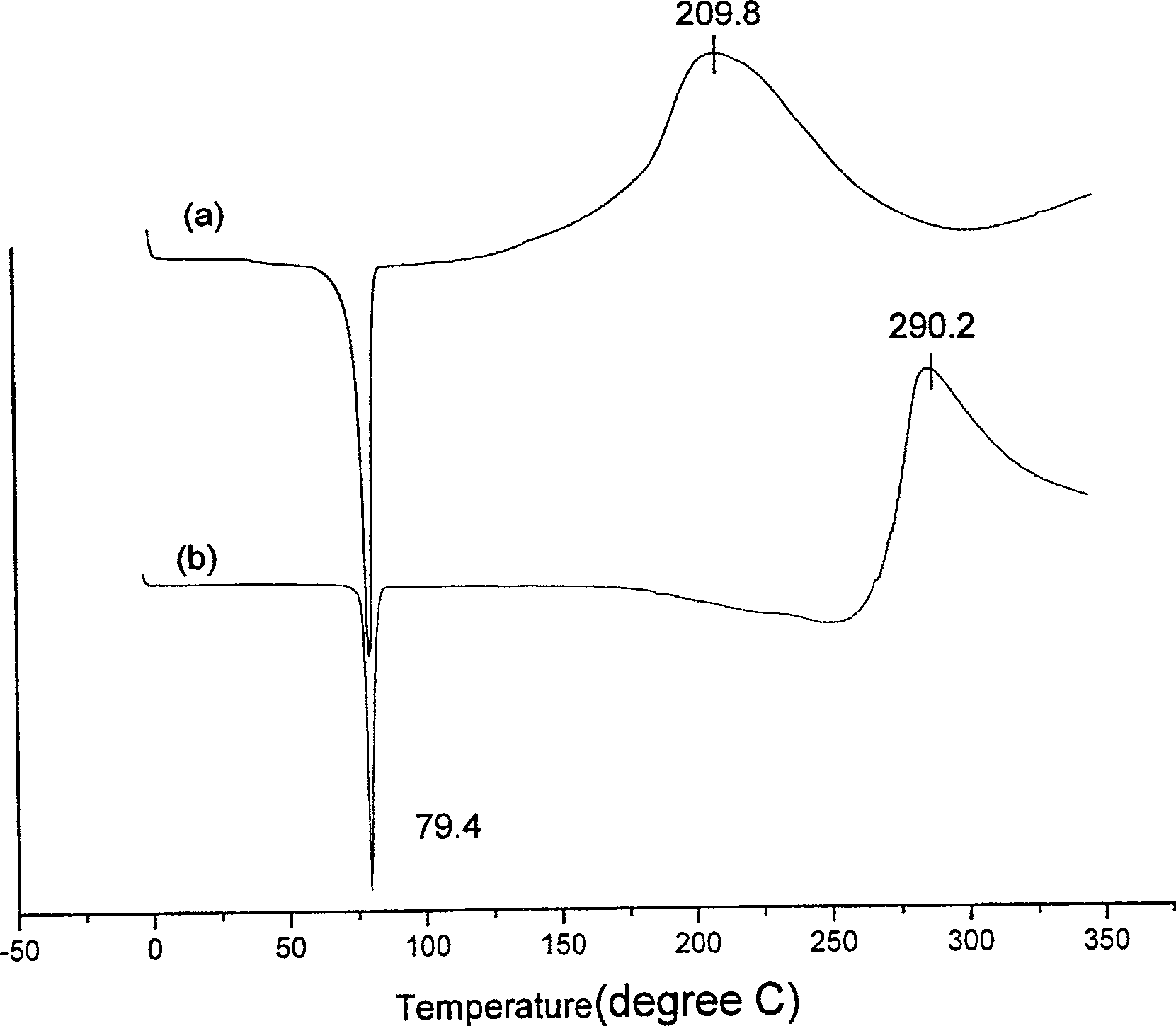

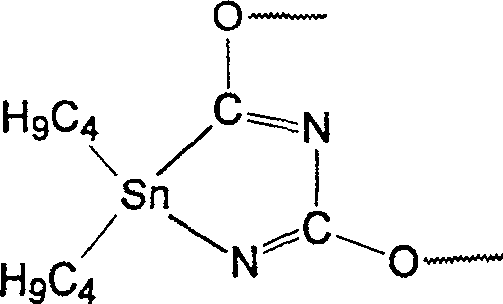

[0045] Preparation of organotin compound (bisphenol A type):

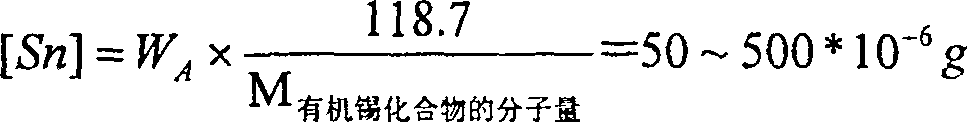

[0046] Weigh 11.4g of dibutyltin dilaurate (DBTDL, 0.018mol) and 10.0g of bisphenol A cyanate (BADCy, 0.036mol) in a beaker, and react at 60-80°C for 20-30min to obtain organotin Compound catalyst, [Sn]=0.1g per 1g of organotin compound.

[0047] Preparation of organotin compound (bisphenol L type):

[0048] Weigh 10.1g of dibutyltin dilaurate (DBTDL, 0.016mol) and 8.5g of 4,4'-dicyanato-diphenylpropane (BEDCy, 0.036mol) in a beaker, and react at 40-70°C for 20 ~30min, the organotin compound catalyst is prepared, [Sn]=0.1g in every 1g of organotin compound.

Embodiment 1

[0050] Weigh 268g of epoxy E-51 resin and place it in a beaker, heat it to 60-80°C in an oil bath, add 10.7g of organotin compound (bisphenol A type), keep the temperature at 60-80°C, and stir for 15min. Heating was stopped, and it was naturally cooled to room temperature to obtain a two-component organotin compound catalyst in the form of light brown viscous liquid. Tin content [Sn]=0.003845g per 1g of two-component catalyst.

Embodiment 2

[0052] Except that epoxy E-51 resin takes by weighing 536g, other is identical with embodiment 1. Tin content [Sn]=0.001922g per 1g of two-component catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com