Composite descaling process of non-stop production of sea pipe throwing balls and descaling agent

A descaling agent and sea pipe technology, applied in cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of reduced transmission efficiency, difficult to pig and descaling effect, and large amount of pipeline dirt, etc., to achieve Improve descaling efficiency and effect, enhance descaling effect and effect of descaling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

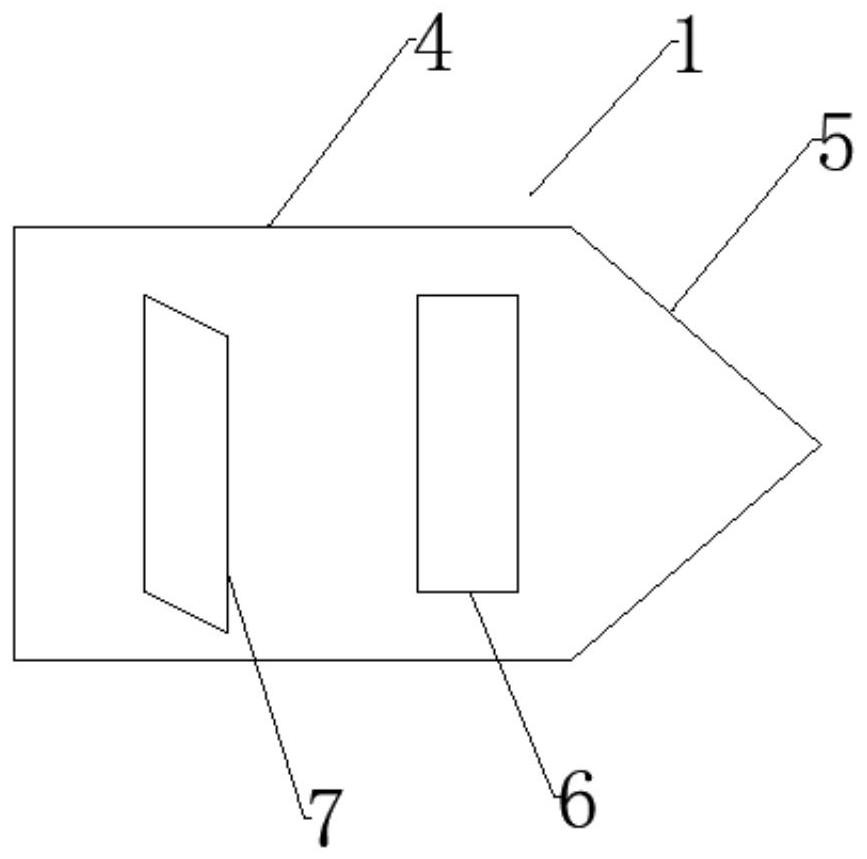

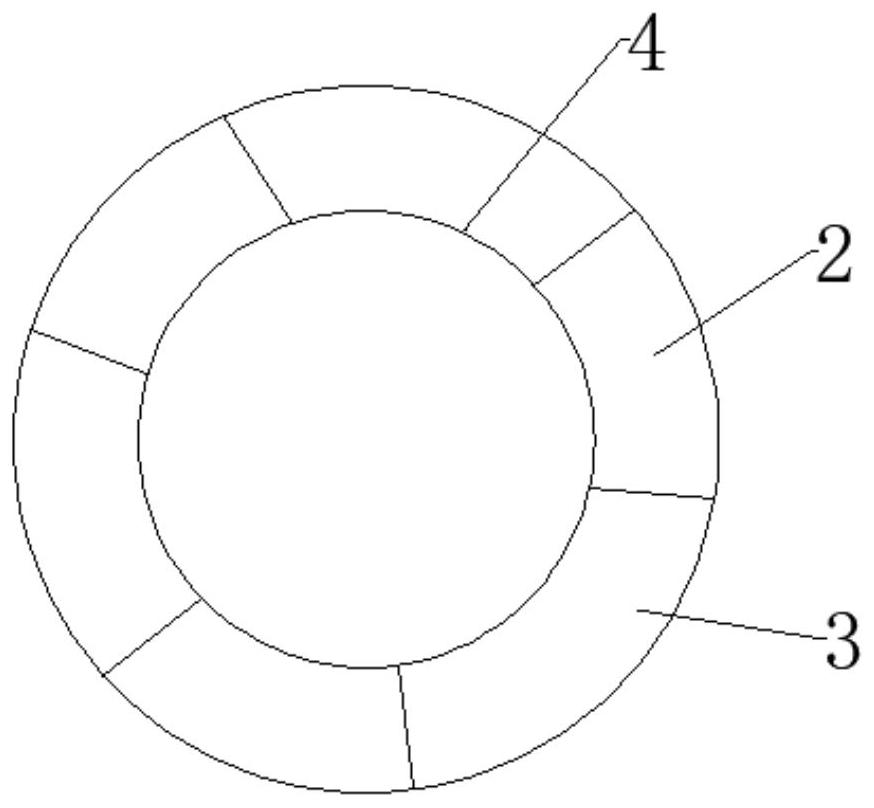

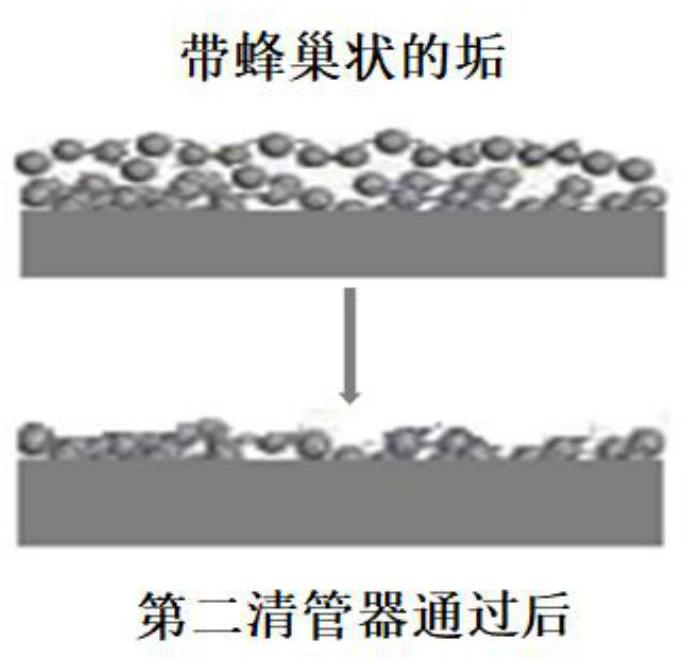

Embodiment 1

[0031] The compound descaling process of non-stop production of sea pipe balls and descaling agent specifically includes: the sea pipe is equipped with a ball inlet near the crude oil inlet, and a ball outlet near the crude oil outlet, and the crude oil flows continuously from the crude oil import to the crude oil outlet. Put the ball into the first pig, and after the first pig flows out from the ball outlet, put it into the second pig, and when the second pig flows to a quarter of the length of the sea pipe, put it into the crude oil inlet Descaling agent, after the descaling agent is put in for 8 hours, put it into the second pipe pig again, the above-mentioned putting into the second pipe pig, descaling agent, and putting it into the second pipe pig again is a complete cleaning process, repeat the above complete The cleaning process until the last time the weight of dirt discharged is less than 3 kg.

[0032] Wherein, the descaling agent includes the following raw materials...

Embodiment 2

[0035]The compound descaling process of non-stop production of sea pipe balls and descaling agent specifically includes: the sea pipe is equipped with a ball inlet near the crude oil inlet, and a ball outlet near the crude oil outlet, and the crude oil flows continuously from the crude oil import to the crude oil outlet. Put the ball into the first pig, and after the first pig flows out from the ball outlet, put it into the second pig, and when the second pig flows to a quarter of the length of the sea pipe, put it into the crude oil inlet Descaling agent, after the descaling agent is put in for 6 hours, it is put into the second pig again, and the above-mentioned putting into the second pig, descaling agent, and putting into the second pig again is a complete cleaning process, repeat the above complete The cleaning process until the last time the weight of dirt discharged is less than 3 kg.

[0036] Among them, the descaling agent includes the following raw materials in parts...

Embodiment 3

[0039] The compound descaling process of non-stop production of sea pipe balls and descaling agent specifically includes: the sea pipe is equipped with a ball inlet near the crude oil inlet, and a ball outlet near the crude oil outlet, and the crude oil flows continuously from the crude oil import to the crude oil outlet. Put the ball into the first pig, and after the first pig flows out from the ball outlet, put it into the second pig, and when the second pig flows to a quarter of the length of the sea pipe, put it into the crude oil inlet Descaling agent, after the descaling agent is put into use for 7 hours, put it into the second pipe pig again, the above-mentioned putting into the second pipe pig, descaling agent, and putting into the second pipe pig again is a complete cleaning process, repeat the above complete The cleaning process until the last time the weight of dirt discharged is less than 3 kg.

[0040] Among them, the descaling agent includes the following raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com