Injection molding machine nozzle cleaning device

A cleaning device and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of pinching, inconvenient, and affecting injection molding, and achieve the effect of easy insertion and shortening the time for cleaning nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

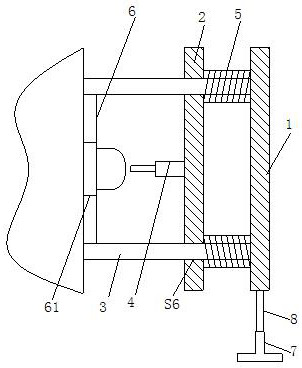

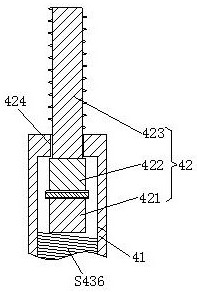

[0021] Such as figure 1 , figure 2 As shown, the injection molding machine nozzle cleaning device described in this embodiment is used to clean the injection molding machine nozzle; it includes a bottom plate 1, a movable plate 2, a limit rod 3, a cleaning mechanism 4 and a first elastic member 5; the movable plate 2 is set On the side of the bottom plate 1 close to the nozzle, the first elastic member 5 is arranged between the bottom plate 1 and the movable plate 2, and is always in a compressed state. One end of the limit rod 3 is fixedly connected to the bottom plate 1, and the other end is connected to the The through hole on the movable plate 2 makes the movable plate 2 slide along the limit rod 3 and maintains a parallel state with the base plate 1 all the time; The second elastic part 43 between the base 41 and the telescopic part 42 is always in a compressed state. The telescopic part 42 includes a fixing part 421 , a limiting part 422 and a heating part 423 . Fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com