Method for degumming flax

A flax-to-mass ratio technology, applied in the chemical post-processing of fibers, textiles and papermaking, fiber processing, etc., can solve the problems of poor degumming effect and long degumming time, so as to improve the degumming effect, enhance the degumming performance, and enhance the degumming effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

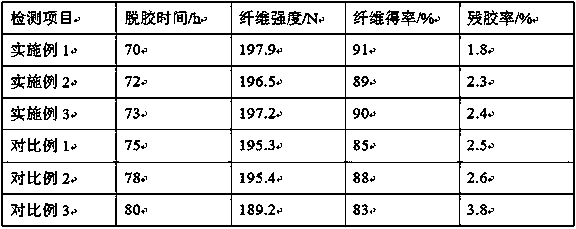

Examples

preparation example Construction

[0028] The preparation method of the soaking solution is as follows: mix the mixed polymer and sodium hydroxide solution at a mass ratio of 3:7-9, heat at 90-95°C for 3 hours, add hydrogen peroxide with 10-15% polyvinyl alcohol quality, and cool down to 70°C. ~75°C, keep warm for 6 hours, add an additive with a mass of polyvinyl alcohol of 34-37%, stir for 1 hour, adjust the pH to neutral, and obtain the soaking solution.

[0029] The preparation method of the trace additive is as follows: mixing ferric chloride, manganese nitrate and water at a mass ratio of 3:1 to 2:12 to obtain the trace additive.

[0030] The auxiliary agent is mixed with calcium citrate and ammonium bicarbonate at a mass ratio of 1:1-3.

[0031] The trace additive is any one of sodium nitrate and magnesium nitrate.

[0032] The preparation method of the nutrient solution is: 150-160 parts of water, 20-30 parts of peptone, 17-19 parts of glucose, 3-6 parts of dipotassium hydrogen phosphate, 4-12 parts of ...

Embodiment 1

[0041] The mixed polymer is formed by mixing polyvinyl alcohol and polyglutamic acid at a mass ratio of 1:5.

[0042] The additive is tetramethyldivinyldisiloxane.

[0043] The preparation method of the soaking solution is: mix the mixed polymer and sodium hydroxide solution at a mass ratio of 3:9, heat at 95°C for 3h, add hydrogen peroxide with 15% polyvinyl alcohol mass, cool down to 75°C, keep it warm for 6h, add Add 37% polyvinyl alcohol as an additive, stir for 1 hour, and adjust the pH to neutral to obtain the soaking solution.

[0044] The preparation method of the trace additive is as follows: mixing ferric chloride, manganese nitrate and water at a mass ratio of 3:2:12 to obtain the trace additive.

[0045] The auxiliary agent is mixed with calcium citrate and ammonium bicarbonate at a mass ratio of 1:3.

[0046] The trace additive is sodium nitrate.

[0047] The preparation method of the nutrient solution is as follows: 160 parts of water, 30 parts of peptone, 19 ...

Embodiment 2

[0056] The mixed polymer is formed by mixing polyvinyl alcohol and polyglutamic acid in a mass ratio of 1:4.

[0057] The additive is methyltriethoxysilane.

[0058] The preparation method of the soaking solution is: mix the mixed polymer and sodium hydroxide solution at a mass ratio of 3:8, heat at 93°C for 3h, add hydrogen peroxide with 13% polyvinyl alcohol mass, cool down to 73°C, keep warm for 6h, add Add 35% polyvinyl alcohol as an additive, stir for 1 hour, and adjust the pH to neutral to obtain the soaking solution.

[0059] The preparation method of the trace additive is as follows: mixing ferric chloride, manganese nitrate and water according to the mass ratio of 3:1.5:12 to obtain the trace additive.

[0060] The auxiliary agent is mixed with calcium citrate and ammonium bicarbonate at a mass ratio of 1:1-3.

[0061] The trace additive is magnesium nitrate.

[0062] The preparation method of the nutrient solution is as follows: 155 parts of water, 25 parts of pep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com