Hollow four-side connector

A hollow, conductive surface technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of excessive conductor overcurrent, short circuit to ground, fire, etc., to increase heat dissipation space, increase the loading surface of the end Great, heat-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

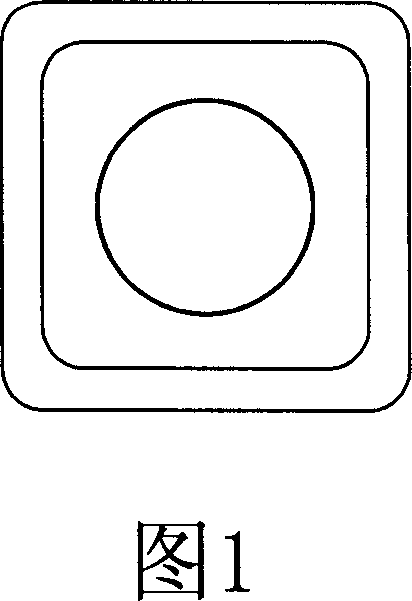

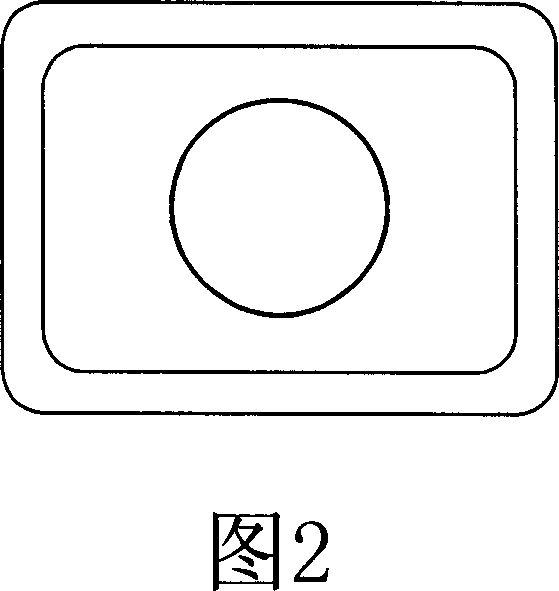

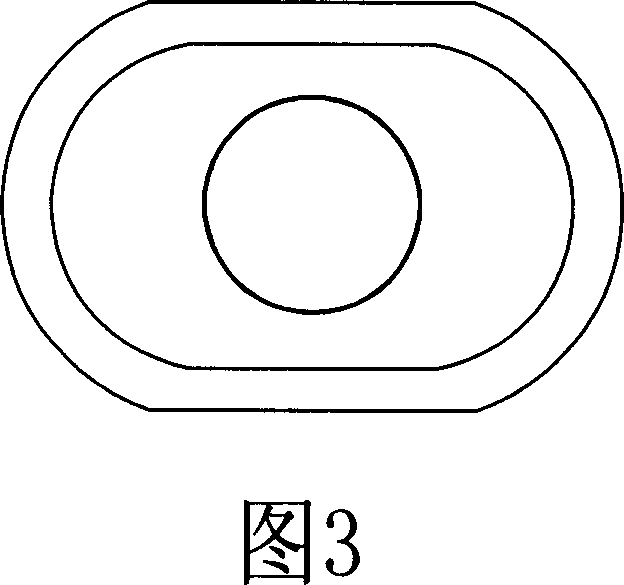

[0010] As shown in Figure 1, the hollow four-sided joint of the present invention is the end pipe diameter of the copper or aluminum pipe busbar and the copper composite pipe busbar (composite steel pipe or aluminum pipe in the copper pipe) with a diameter of Φ30mm to 500mm and a wall thickness of 1mm to 30mm. Use a punch or hydraulic press to stamp and form 4 copper and aluminum conductive surfaces, and configure a suitable mold to process the conductive surfaces (square, rectangular, 2-plane oval) according to the actual current carrying capacity requirements and the requirements of the busbar pipe diameter. There is a certain heat dissipation space distance between the 4 copper and aluminum conductive planes, and then the 4 copper and aluminum conductive planes formed by stamping are fastened with rectangular conductors or soft connections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com