Compressed air type mechanical part cleaning machine and use method thereof

A technology for compressed air and mechanical parts, applied in the field of compressed air mechanical parts cleaning machines, can solve the problems of difficult real-time monitoring of parts, low efficiency of manual cleaning, and sparks, so as to eliminate the risk of combustion and explosion, The effect of eliminating the risk of sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

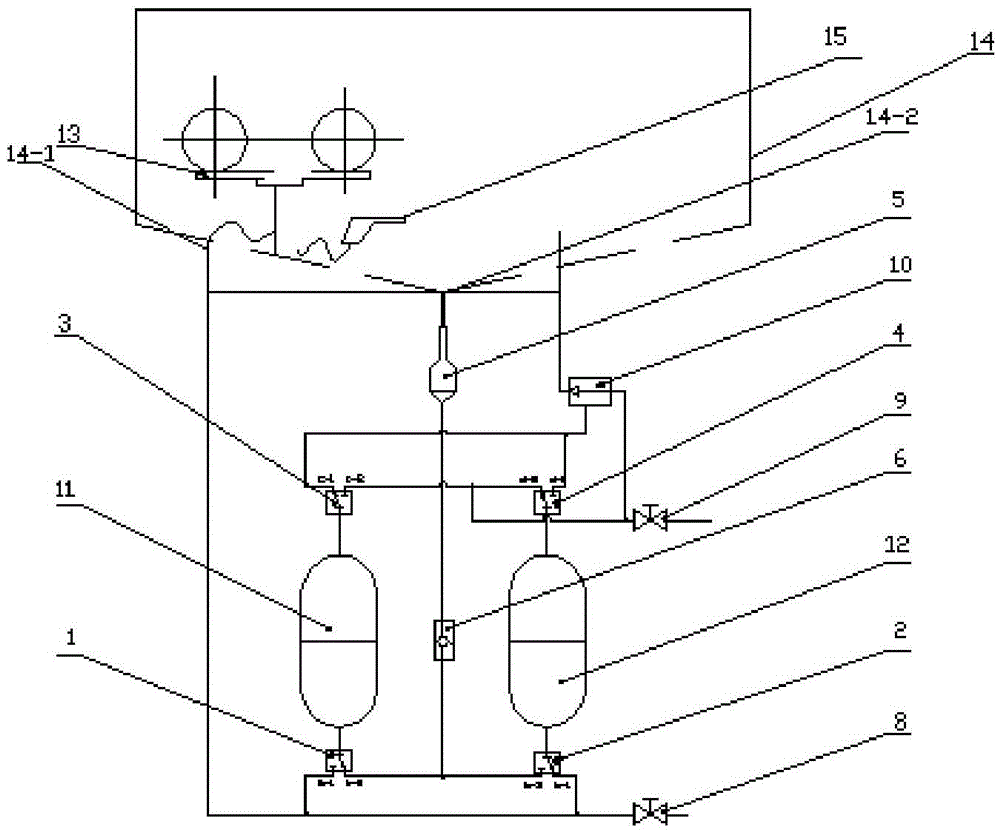

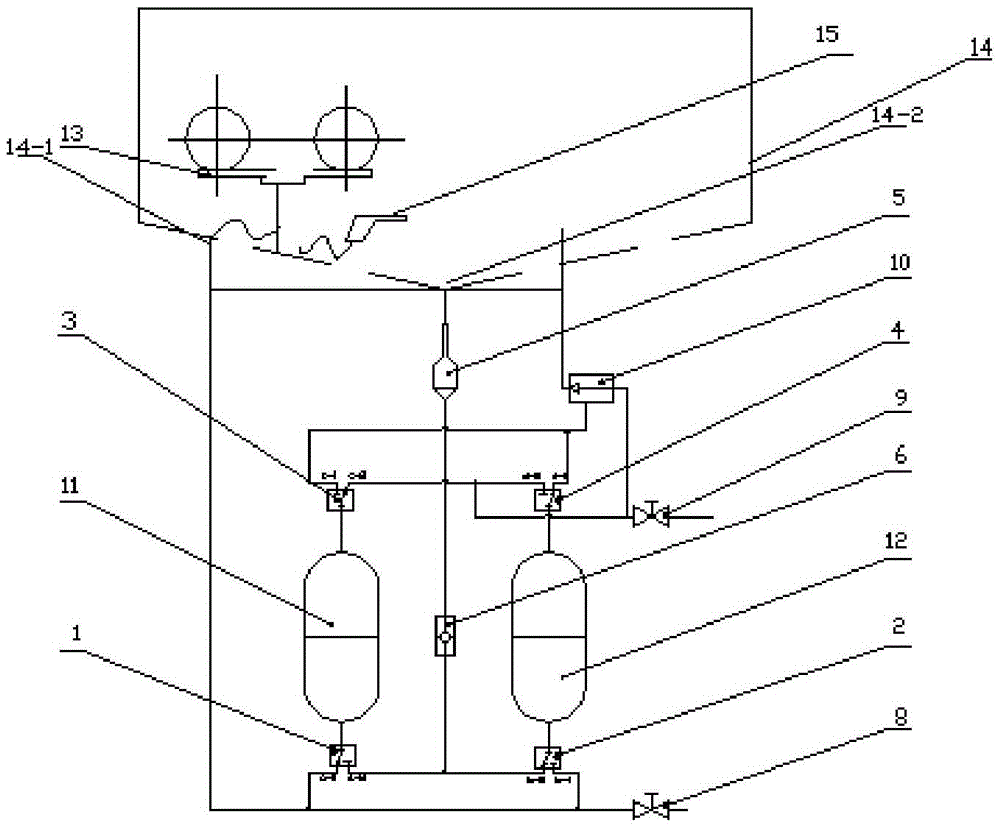

[0025] The compressed air type mechanical parts cleaning machine comprises a cleaning chamber 14 and a cleaning liquid circulation system. The cleaning chamber 14 is provided with a workbench 13 (the workbench 13 can rotate 360°), a cleaning chamber inflow port 14-1 connected to the spray gun 15 and The cleaning chamber outlet 14-2; the cleaning liquid circulation system includes a cleaning liquid filter 5 (preferably, the cleaning liquid filter 5 is U-shaped, and the U-shaped bottom is provided with a groove for containing impurities, and the outlet of the filter is provided with There are filters), one-way valve 6, pressure vessel 11 and liquid storage tank 12; the two ends of pressure vessel 11 are respectively provided with three-way valve a1 and three-way valve c3, the interface a-1 of three-way valve a1 and the flow of cleaning chamber The inlet 14-1 is connected, the interface a-2 of the three-way valve a1 is connected with the one-way valve 6; the interface c-1 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com