Heat dispersion connector

A heat-dissipating and joint technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of high cost of converting fittings, burning of busbars, and fires, etc., to achieve light weight, increase heat dissipation space, and reduce fire. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

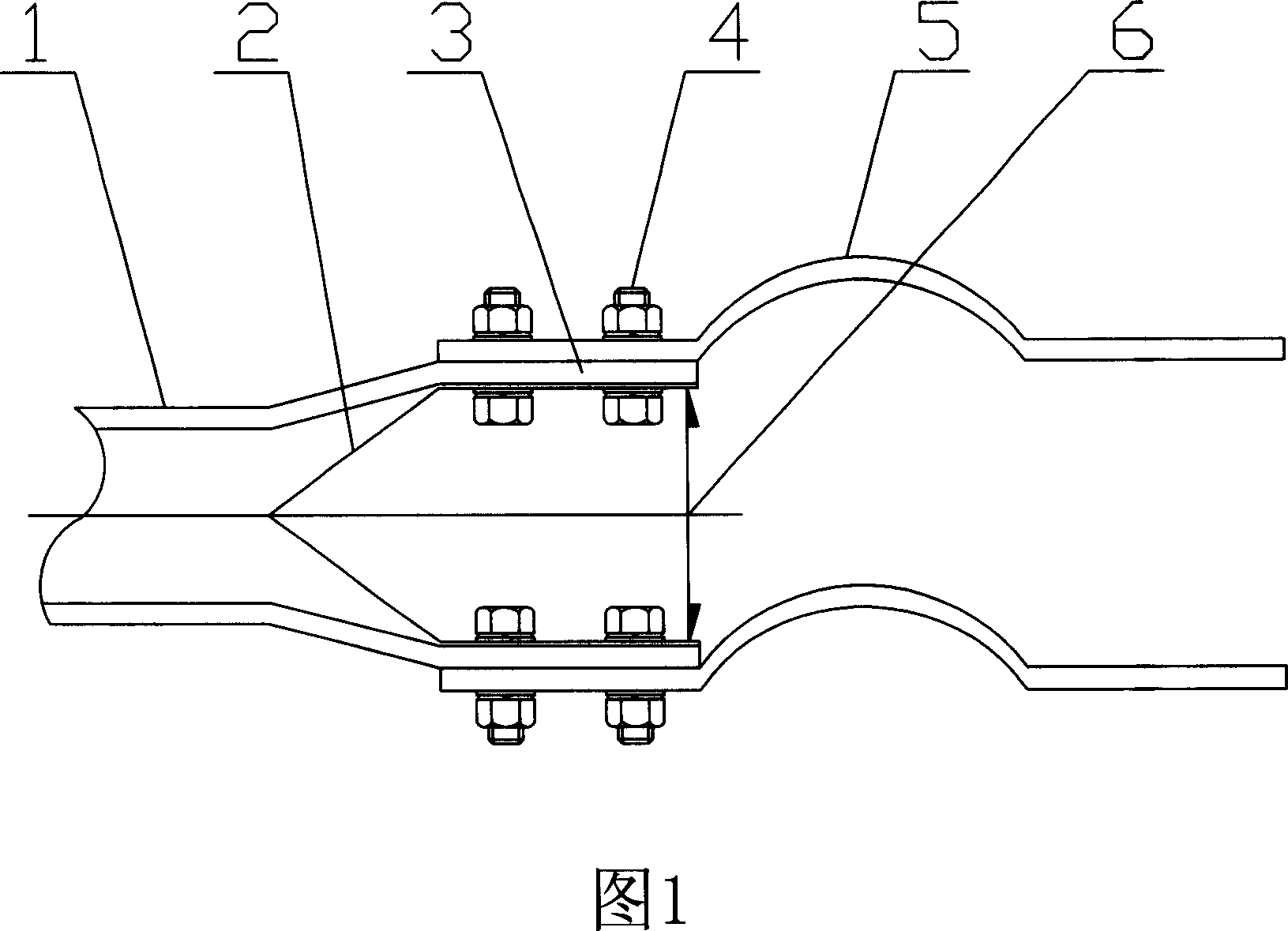

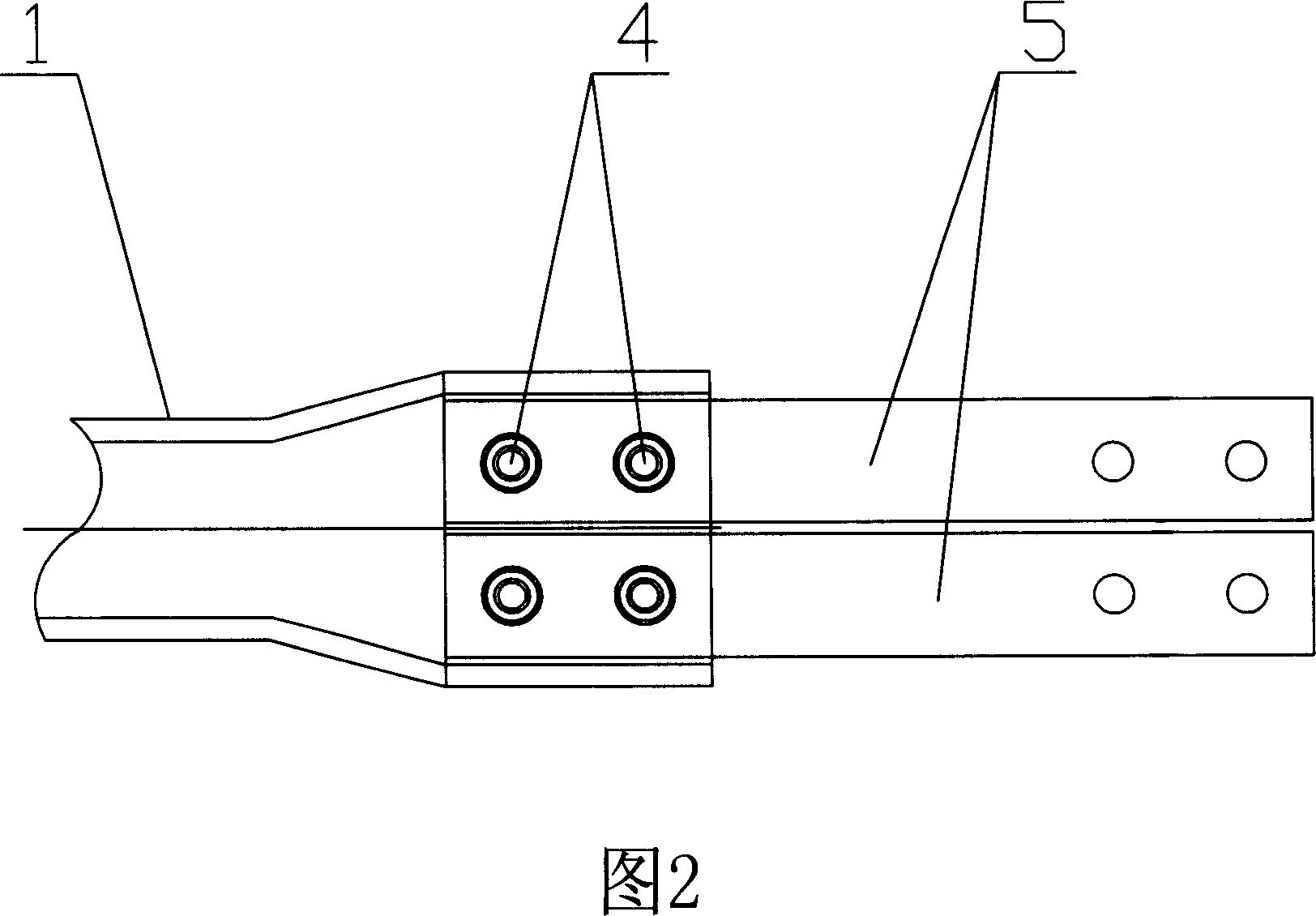

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

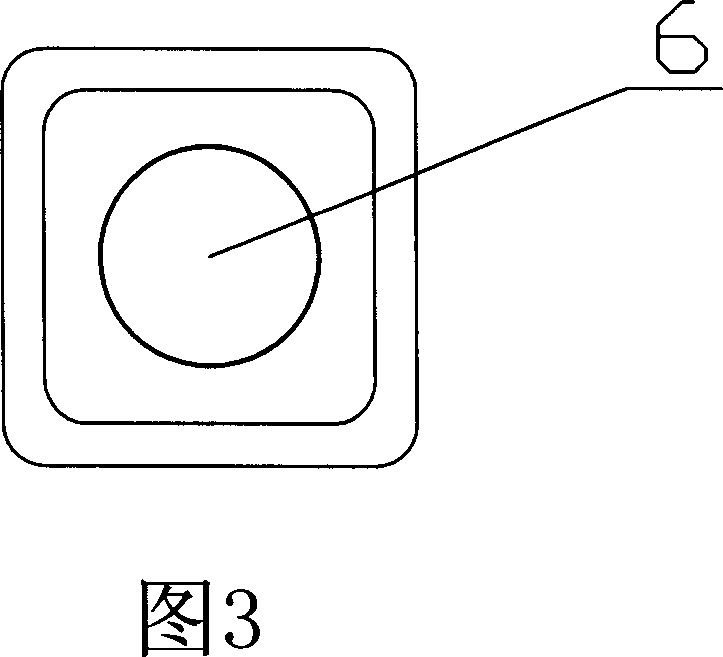

[0019] As shown in Fig. 1 and Fig. 2, the first embodiment of the present invention is to divide the end of the pipe busbar with a diameter of Φ30mm to 500mm and a wall thickness of 1mm to 30mm (the length of about twice the diameter of the pipe busbar) into two semicircles, Then the two semicircles are punched into two conductive surfaces by stamping process. There are reinforcing ribs on both sides of the two conductive surfaces, and there is a certain heat dissipation space between the two conductive surfaces. Or soft connection is connected with other equipment, which forms a heat-dissipating heat-dissipating joint.

[0020] As shown in Figure 6 and Figure 7, the second specific embodiment of the present invention is to use a punch press or a hydraulic press to form four conductive surfaces with a diameter of Φ30mm to 500mm and a wall th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com