Equipment and technology for preparing metal powder

A technology of metal powder and equipment, which is applied in the field of ion atomization process to produce metal powder, can solve the problems of slowing down of the drive mechanism, low efficiency of metal powder, and low utilization rate of raw materials, so as to maintain continuity, improve utilization rate, Effect of Raw Material Utilization Ratio Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

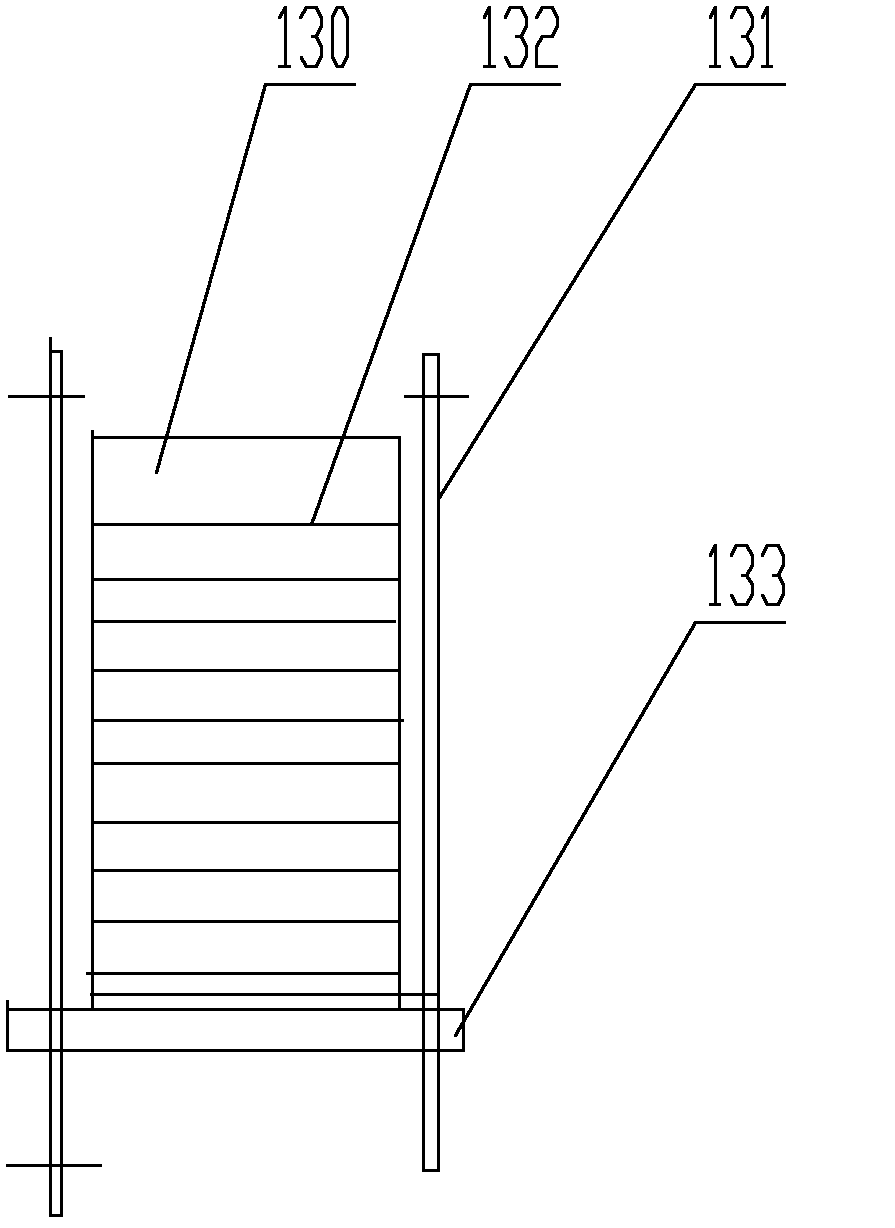

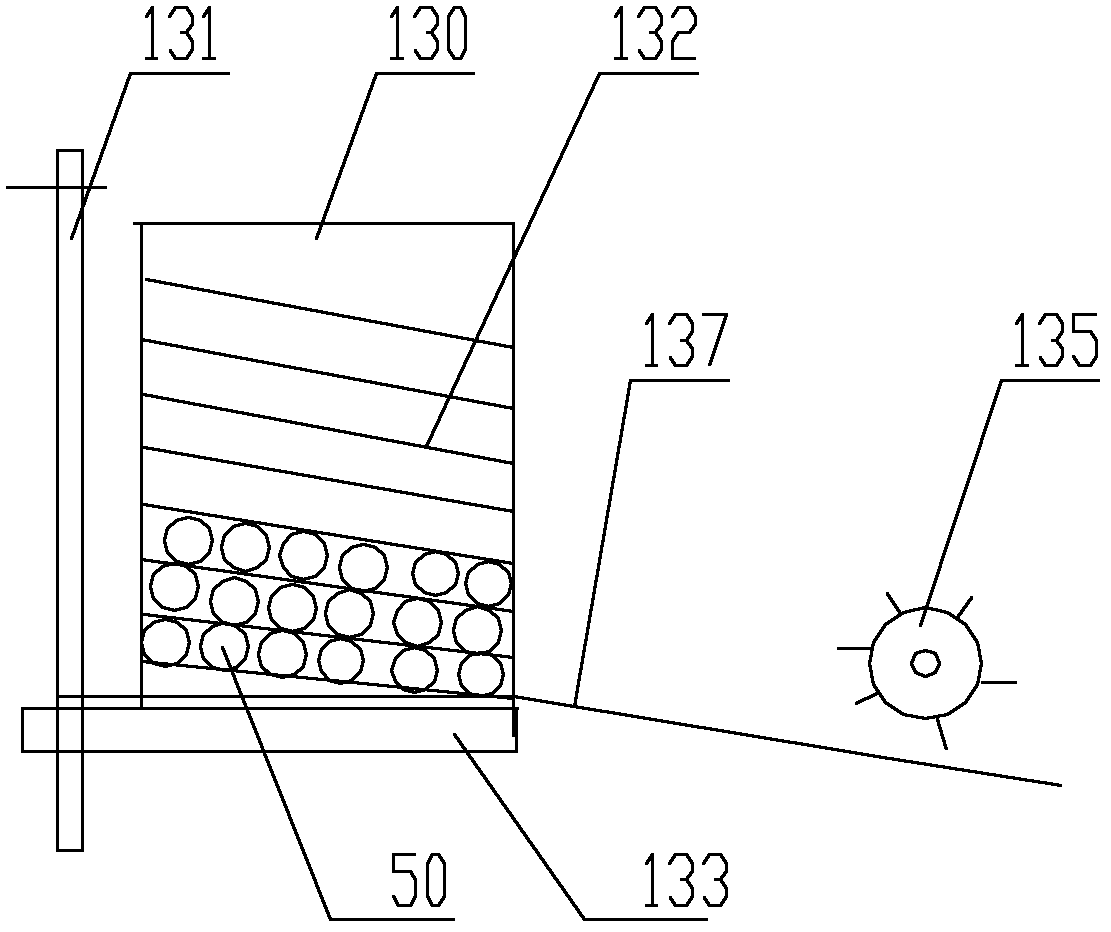

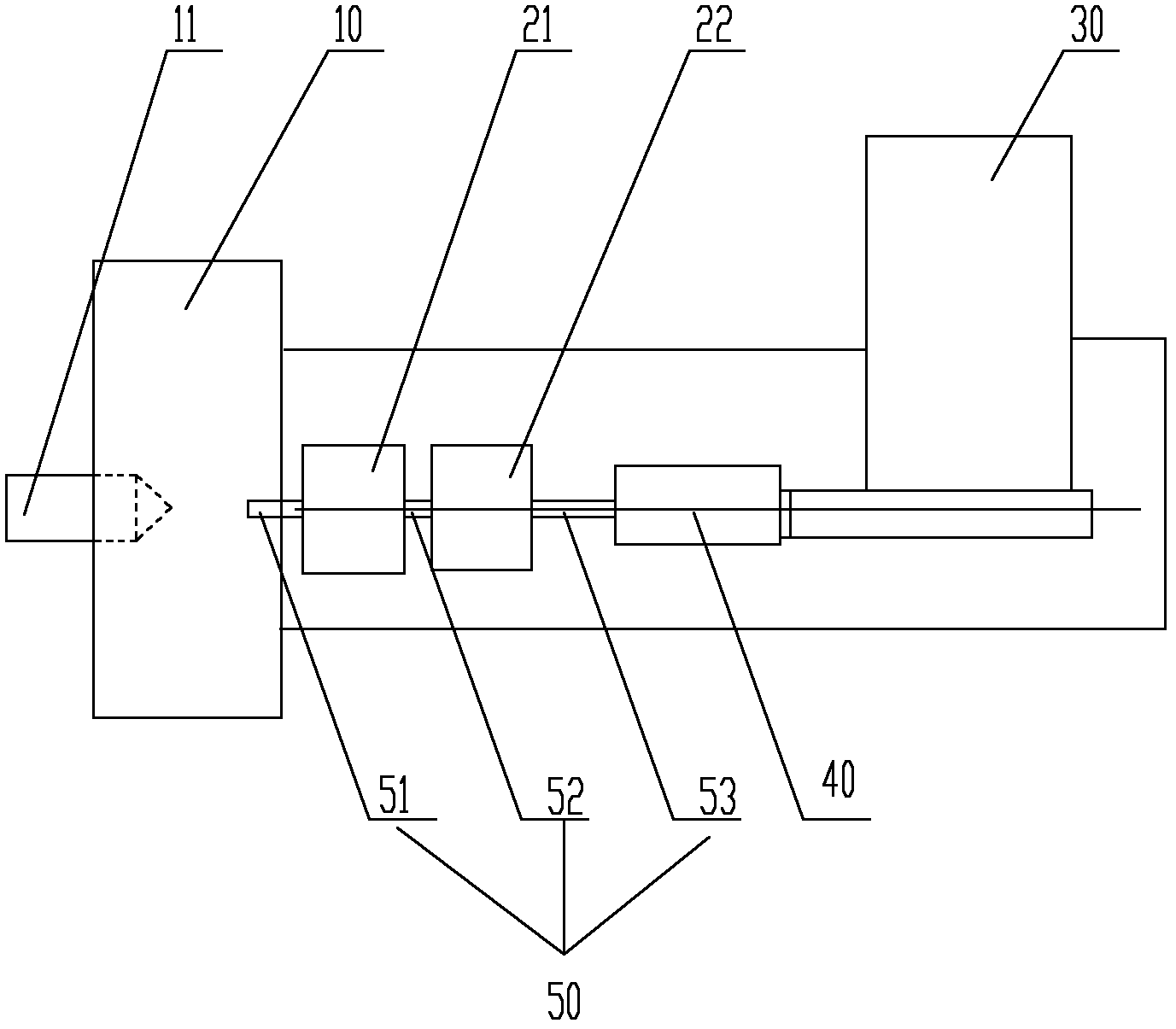

[0037] Such as image 3 with Figure 4 As shown, the present invention proposes a kind of equipment for producing metal powder, is used for atomizing raw material rod 50 into metal powder, and the present invention proposes to adopt the plasma gun 11 that is arranged in the atomization chamber 10 to extend into in the atomization chamber The high-speed rotating metal raw material rod 50 acts, and the described equipment for producing metal powder includes: a drive mechanism 21 for driving the first raw material rod 50 to rotate, such as Figure 6 to Figure 8 As shown, the drive mechanism 21 includes: a motor (not shown in the figure) of the drive mechanism, a drive roller 211 of the drive mechanism connected to the motor shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com