Production method for drawing type expanded extra-large-caliber J55 casing pipes

A production method, a drawing technology, is applied in the production field of the drawing expansion J55 casing with a large diameter, which can solve the problems of inability to achieve wall reduction, poor surface quality, and large bending degree of the pipe end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

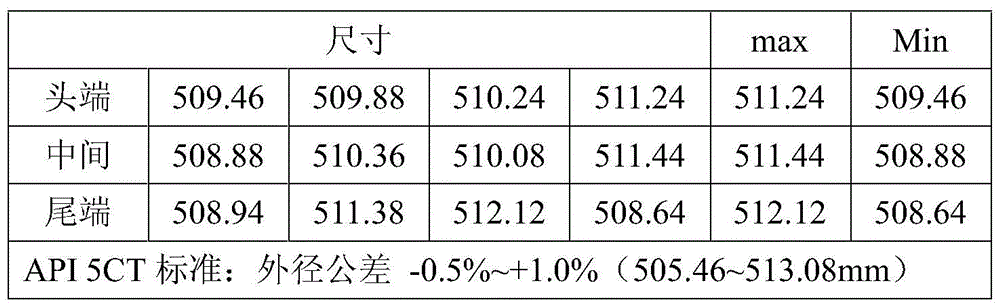

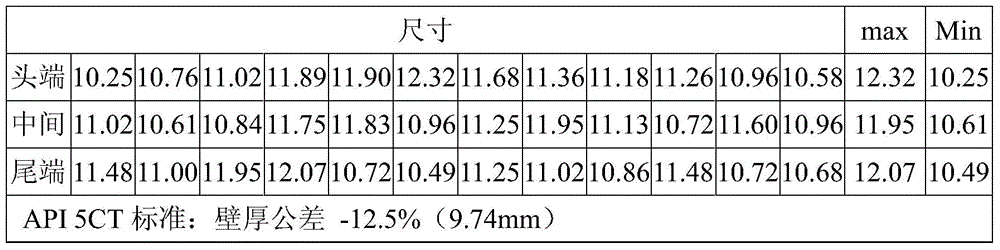

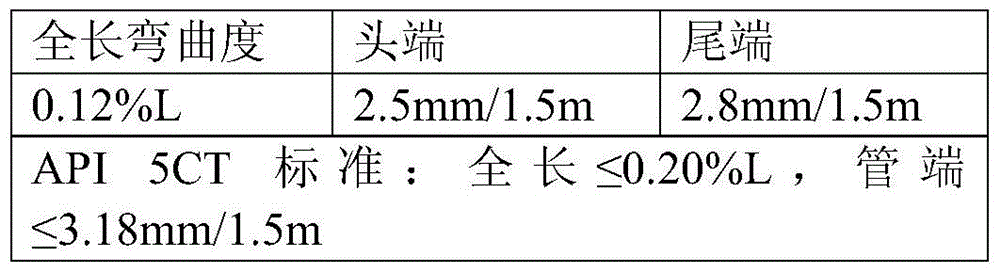

[0029] Embodiment 1 provides a method for producing 508.00×11.13mm J55 casing, the specific process flow is:

[0030] (1) Provided by 340 continuous rolling pipe unit Tube blank. Specifically, first smelting and forming an alloy liquid whose composition is C0.34-0.41%, Si0.17-0.37%, Mn1.25-1.60, P / S≤0.028% by weight percentage, to make a continuous casting round billet; then Continuously cast round billets are rolled into specification steel pipes.

[0031] (2) The pipe end is heated and the bell mouth is expanded. Specifically, one end of the steel pipe provided in step (1) is heated to 900° C. in a slot furnace, wherein the length of the heated pipe end is 300 mm. Then expand the pipe end into a bell mouth, the diameter of which is 710mm.

[0032] (3) Carry out the first heating expansion in the walking furnace. Specifically, the heating temperature is 980°C, the first pass is expanded to 395×14.3mm, the second pass is expanded to 418×13.6mm, and the third pass is fi...

Embodiment 2

[0053] Embodiment 2 provides a method for producing 508.00×11.13mm J55 casing, the specific process flow is:

[0054] (1) Provided by 340 continuous rolling pipe unit Tube blank. Specifically, first smelting and forming an alloy liquid whose composition is C0.34-0.41%, Si0.17-0.37%, Mn1.25-1.60, P / S≤0.028% by weight percentage, to make a continuous casting round billet; then Continuously cast round billets are rolled into specification steel pipes.

[0055] (2) The pipe end is heated and the bell mouth is expanded. Specifically, one end of the steel pipe provided in step (1) is heated to 1000°C through a slot furnace, wherein the heated length of the end of the pipe is 400 mm. Then expand the pipe end into a bell mouth, and the diameter of the bell mouth is 720mm.

[0056] (3) Carry out the first heating expansion in the walking furnace. Specifically, the heating temperature is 990°C, the first pass is expanded to 400×14.2mm, the second pass is expanded to 425×13.5mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com