High-strength and high-elasticity copper-titanium alloy and manufacturing method thereof

A technology of copper-titanium alloy and manufacturing method, which is applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of long production process flow, unfavorable rapid large-scale production, and low yield, so as to improve quality and formability Good, high purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] High-strength high-elastic copper-titanium alloys were percentage: Ti2.8%, Ni0.03%, Fe0.15%, Y0.03%, La 0.02%, and the rest of Cu and inevitable impurity elements.

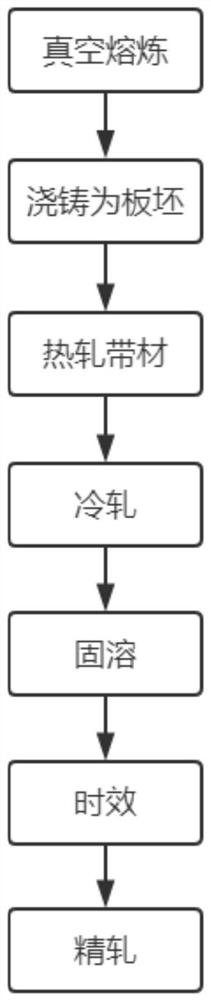

[0025] (1) Vacuum smelting: Gao Pure copper, high-purity titanium, electrolyte nickel, etc., in proportion to the vacuum induction furnace, first put a large number of raw materials, and the looseness, avoid the bridge, then vacuum until 20Pa Paving electricity melting, the melting temperature is 1190 ° C, after the melting refinement of 3 minutes, adding the appropriate amount of Y and La, the total refining time is 11 min;

[0026] (2) Pouring is a slab: the molten liquid alloy is cast into a slab under atmosphere protection, and the temperature is 1150 ° C, the slab is 600 mm × 180 mm;

[0027] (3) Hot rolled strip: Take a homogenization treatment of 10 h in an 880 ° C heating furnace after the casting slabs after casting is placed in a 880 ° C heating furnace, and then heat rolled in a thickness of 3 mm at ...

Embodiment 2

[0034] The percentage of elemental quality in high-strength high-elastic copper-titanium alloys was: Ti3.0%, Ni0.04%, Fe0.18%, Y0.03%, La 0.03%, and the rest were Cu and inevitable impurity elements.

[0035] (1) Vacuum smelting: Gao Pure copper, high-purity titanium, electrolyte nickel, etc., in proportion to the vacuum induction furnace, first put a large number of raw materials, and the looseness, avoid the bridge, then vacuum until 20Pa PV-based melting, melting temperature is 1230 ° C, after refining refining for 4 minutes, adding the amount of Y and La, the total refining time is 13 min;

[0036] (2) Pouring as slab: Pouring the liquid alloy of the smelting in the atmosphere protective conditions, the temperature is 1180 ° C, the slab is 750 × 200 mm;

[0037] (3) Hot rolled strip: Take a homogenization treatment for homogenization of 14 h after holding the cast slab cleaning and polished, and then heats up for homogenization, and then heat rolled on 760 to 860 ° C to a shee...

Embodiment 3

[0044] High-strength high-elastic copper-titanium alloys were percentage: Ti3.3%, Ni0.16%, FE0.21%, Y0.04%, La 0.03%, and the rest were Cu and inevitable impurity elements.

[0045] (1) Vacuum smelting: Gao Pure copper, high-purity titanium, electrolyte nickel, etc., in proportion to the vacuum induction furnace, first put a large number of raw materials, and the looseness, avoid the bridge, then vacuum until 20Pa The electricity melting, the melting temperature is 1240 ° C, and the amount of Y and La is added after the refinement of refining for 4 minutes, and the total refining time is 14 min;

[0046] (2) Pouring is a slab: the molten liquid alloy is cast into a slab under atmosphere protection, and the temperature is 1190 ° C, the slab is 750 × 200 mm;

[0047] (3) Hot rolling strip: Take the homogenization of the water after the casting slab cleaning and polishing is placed in a 900 ° C heating furnace, and then heat rolled onto a sheet having a thickness of 5 mm at 780 to 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com