Device and method for preparing high-purity copper and copper alloy ingot

A technology of copper alloy and high-purity copper, which is applied in the field of metallurgy, can solve the problems of ultra-high-purity copper ingots, such as low gas element content, low physical quality, rough surface, and large shrinkage cavities, so as to avoid easy damage and cause ingot pollution, and improve Production efficiency and production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

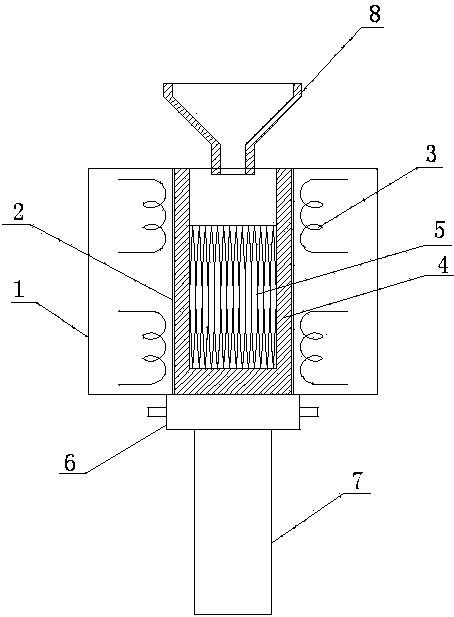

[0020] Such as figure 1 As shown, a device for preparing high-purity copper and copper alloy ingots includes a heating furnace 1, a casting mold channel 2 is arranged in the heating furnace 1, and a number of heating elements 3 are evenly arranged in the furnace wall of the heating furnace 1, and the heating furnace 1 The bottom of the casting mold 4 is provided with a cooling bracket 6, the casting mold channel 2 is provided with a casting mold 4, the bottom of the casting mold 4 is connected with the cooling bracket 6, the top of the casting mold 4 is provided with a funnel-shaped tundish 8, and the bottom of the cooling bracket 6 is connected with a traction device 7 . The molten copper or copper alloy melt 5 is injected into the mold 4 through the tundish 8 .

[0021] A method for preparing high-purity copper and copper alloy ingots, using the above-mentioned device for preparing high-purity copper and copper alloy ingots, and comprising the following specific steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com