A four-pin spot welding head device

A spot welding head and welding head technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of inaccurate grasp of the angle, low speed of needle adjustment, and poor spot welding accuracy, etc. Spot welding accuracy and spot welding quality, improving the speed of needle adjustment, and the effect of welding quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

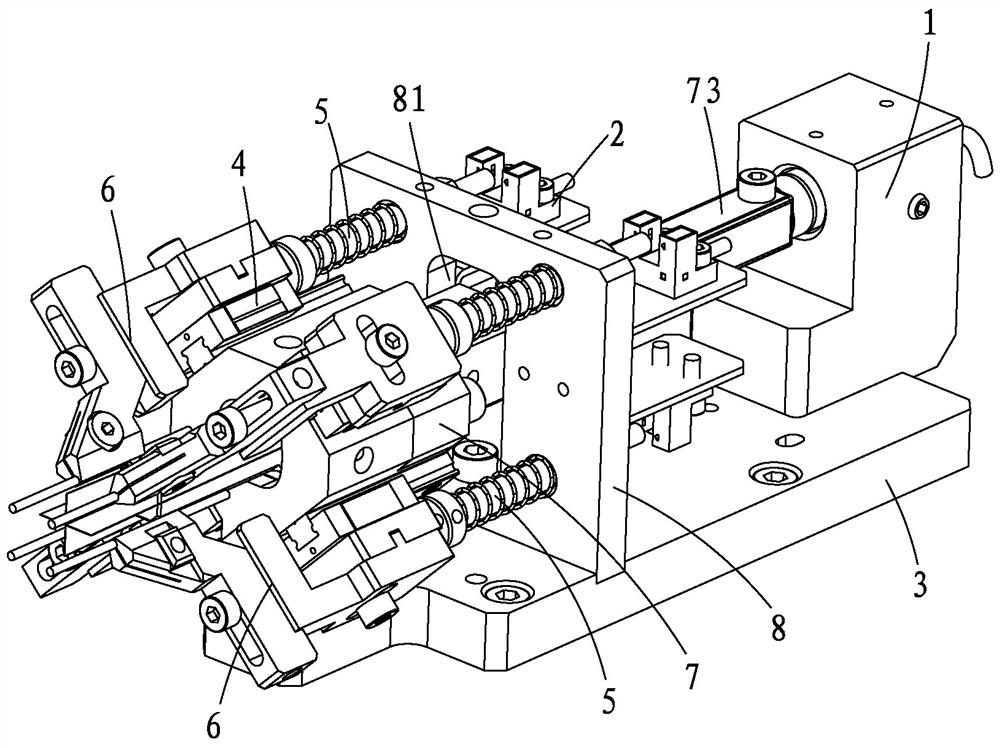

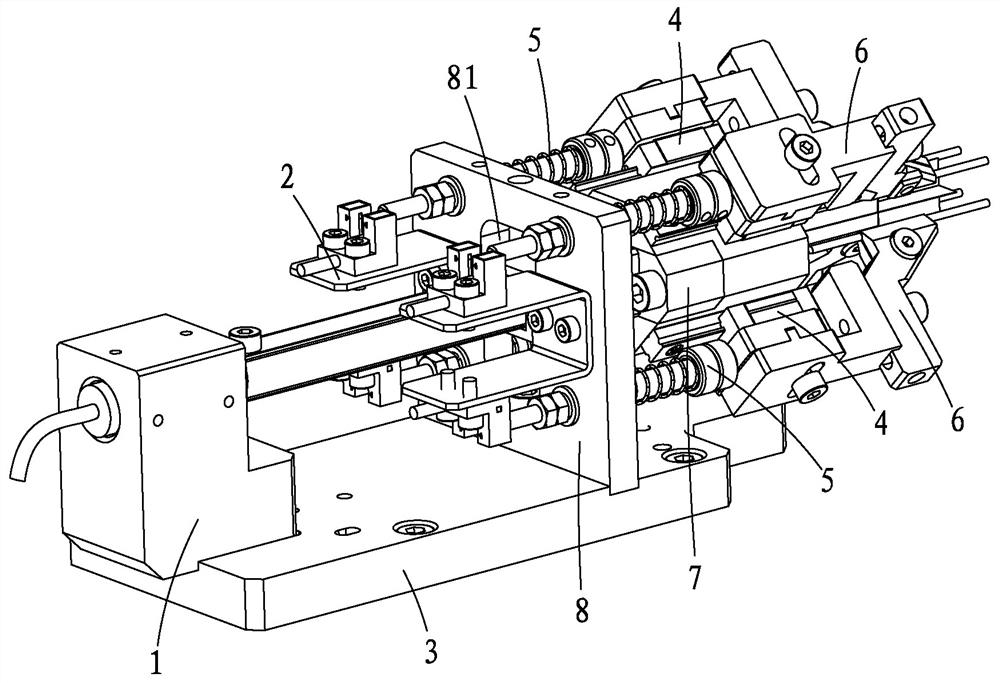

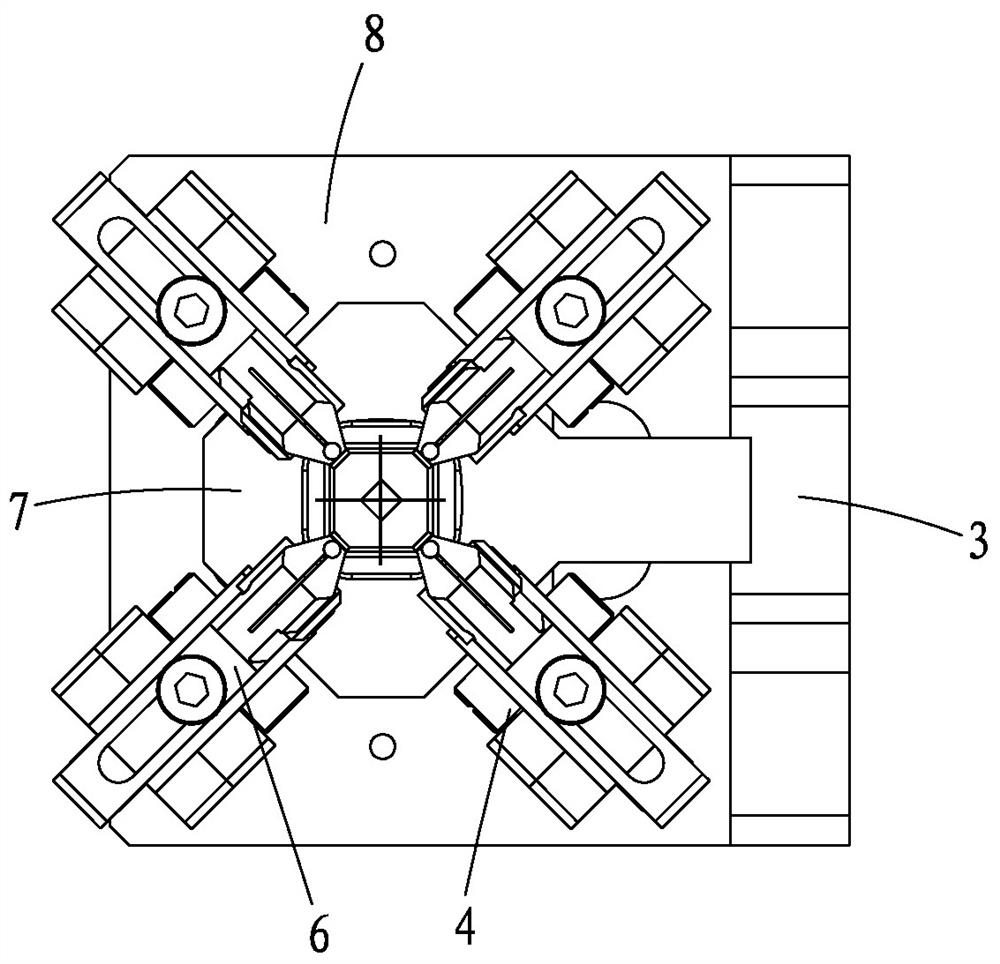

[0030] See Figure 1 to Figure 9 Show, a better embodiment of a four -needle welding header device 100, including a laser -to -pair mechanism 1. One position sensing mechanism 2. One fixed base 3. One welding needle -oriented mechanism 4. One pressure adjustment mechanism 5. One welding needle position adjustment mechanism 6 and one fast welding needle adjustment mechanism 7;

[0031] The central part of the fixed base 3 has a little welding head plate 8, and there is an open hole 81 in the middle of the welding head plate 8. And the center setting of the fast welding needle adjustment mechanism 7 is set with a guide pore 71; the position sensing mechanism 2 is set at the back end of the point welding head plate 8, and the laser -pairing mechanism 1 is set to the fixed fixed fixed fixation. On the base 3, and the laser pairing mechanism 1 is at the back end of the position sensing mechanism 2;

[0032] The position adjustment mechanism of the welding needle position 6 is a mobile co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com