Clamp for battery charge-discharge test

A charge-discharge test and battery technology, applied in the direction of the casing of the measuring device, can solve the problems of unstable clamping of cylindrical batteries, easy short-circuit of batteries, etc., and achieve the effect of avoiding battery skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a battery charge and discharge test fixture, including:

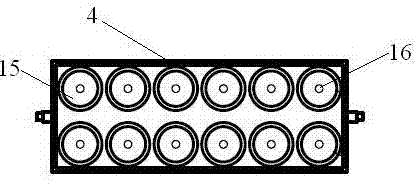

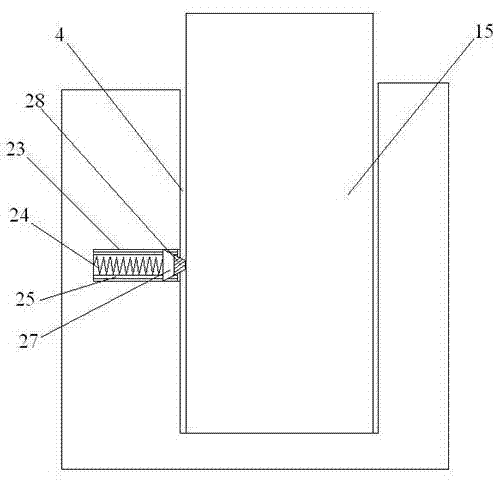

[0048] The base 3 is provided with a plurality of positioning grooves 4 on the base 3, each of the positioning grooves 4 is suitable for vertically inserting the battery 15, and the bottom end of each of the positioning grooves 4 is provided with a negative connection piece, so The negative connecting piece is connected to the charging and voltage sampling negative wire harness 7; the depth of the positioning groove 4 in this embodiment is 1 / 3 of the height of the battery 15; as an optional embodiment, the positioning groove 4 The depth can be set as 1 / 5-4 / 5 of the height of the battery 15; the reason is that within this depth range, the stable positioning of the battery can be realized, and at the same time, it is convenient to take and place the battery.

[0049] The upper cover, the upper cover in this embodiment is set as a flat plate, and a plurality of positive contacts are arranged...

Embodiment 2

[0053] The battery charge and discharge test fixture provided in this embodiment includes:

[0054] The base 3 is provided with a plurality of positioning slots 4 , each of which is suitable for vertically inserting a battery 15 , and a negative connection piece is provided at the bottom of each of the positioning slots 4 . The negative connecting piece is connected to the charging and voltage sampling negative wiring harness 7; the depth of the positioning groove 4 in this embodiment is 1 / 5 of the height of the battery 15.

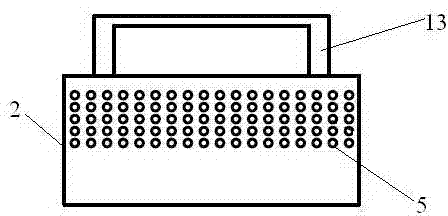

[0055] The upper cover, the upper cover includes a cover plate 1 and a cover body 2 connected to each other, and a plurality of positive contacts are arranged on the lower surface of the cover plate 1, and the positive contacts are connected with the charging and voltage sampling positive wire harness 6 connected, the plurality of positive contacts are set in one-to-one correspondence with the negative connecting pieces of the plurality of positioning gro...

Embodiment 3

[0058] The battery charge and discharge test fixture provided in this embodiment includes:

[0059] Base 3, such as figure 1 As shown, a plurality of positioning grooves 4 are provided on the base 3, each of the positioning grooves 4 is suitable for vertically inserting the battery 15, and the depth of the positioning grooves 4 in this embodiment is 100% of the height of the battery 15 3 / 5; a negative connection piece is provided at the bottom of each positioning slot 4, and the negative connection piece is connected to the charging and voltage sampling negative wire harness 7; between the upper surface and the lower surface of the base 3 An exhaust channel is provided, and the exhaust channel runs through a pair of sides of the base 3, and an exhaust fan 9 is arranged at both ends of the exhaust channel; each of the positioning grooves 4 is connected to the The exhaust channels are connected. Also be provided with temperature testing device in described locating groove 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com