Bed batten trimming tool

A finishing tool and tooling technology, applied in the direction of manufacturing tools, wood processing appliances, multi-purpose machinery, etc., can solve the problems of large manpower input, reduced bed slat finishing quality, low bed slat finishing quality, etc., to improve the finishing quality, Scientific and reasonable structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

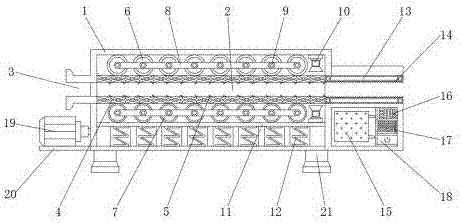

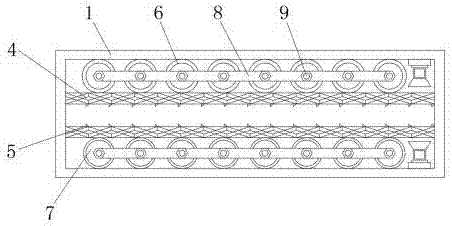

[0016] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a bed slat trimming tool, including a tool body 1, a trimming chamber 2, a slat inlet 3, a synchronous knife tooth belt 4, a trimming knife tooth 5, a leveling roller 6, and a drive roller 7 , coupling rod 8, synchronous turbine 9, level detector 10, decompression plate 11, decompression spring 12, transmission tooth belt 13, finishing knife tooth 14, power supply 15, PLC controller 16, inverter 17, control Switch 18, motor 19, fixed plate 20 and support base 21, the middle end of tooling body 1 is provided with trimming chamber 2, the left side of trimming chamber 2 is provided with slat inlet 3, and the upper and lower sides of trimming chamber 2 are provided with synchronous cutter teeth Belt 4, trimming cutter teeth 5 are arranged on the inner and outer surfaces of the synchronous knife-toothed belt 4, a smoothing roller 6 is arranged above the synchronous knife-toothed belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com