Conveying mechanism

A technology for conveying mechanisms and gaskets, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve problems such as difficult management, yield loss, and cumbersome processes, so as to avoid wasting production capacity, save production costs, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

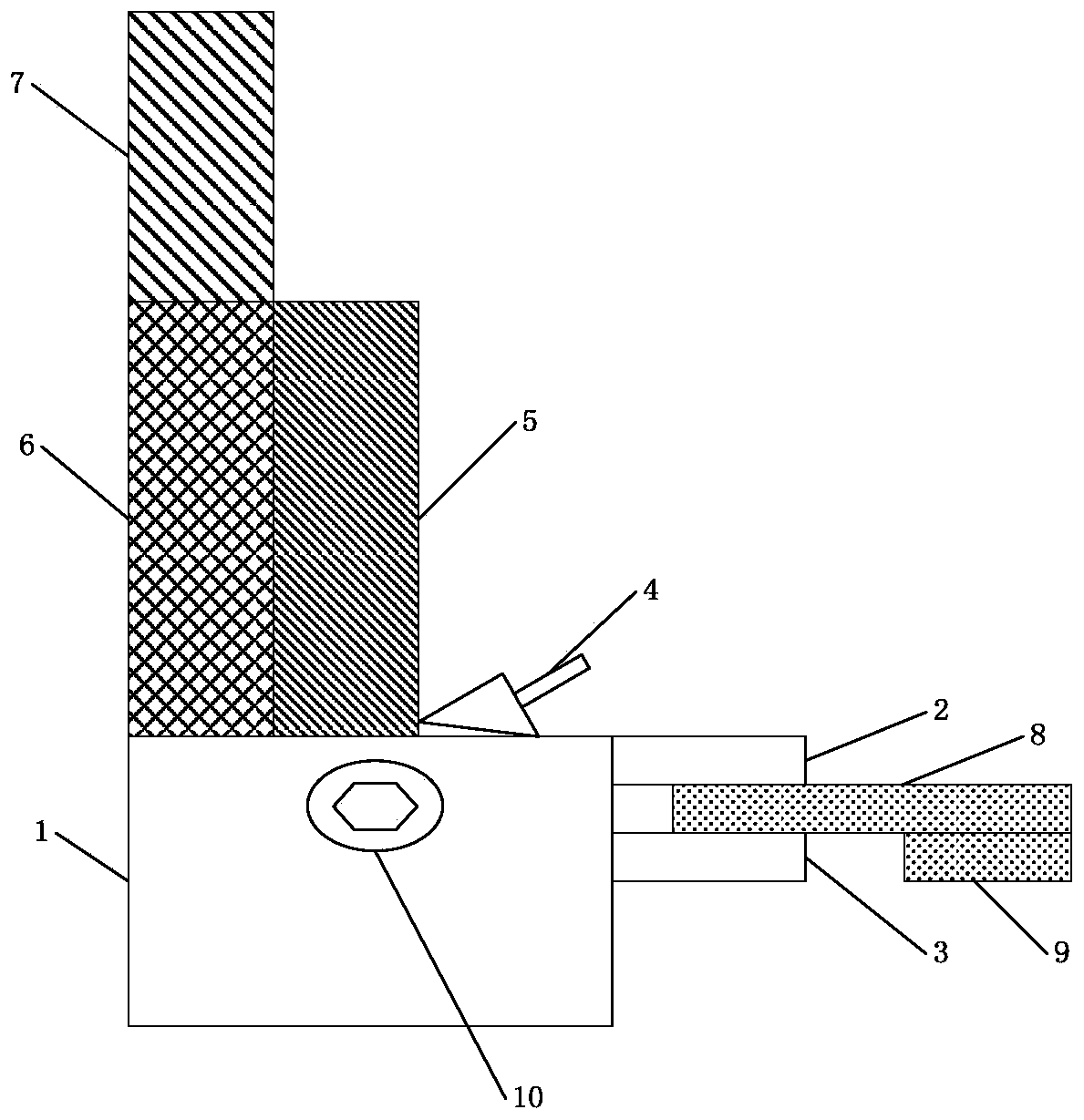

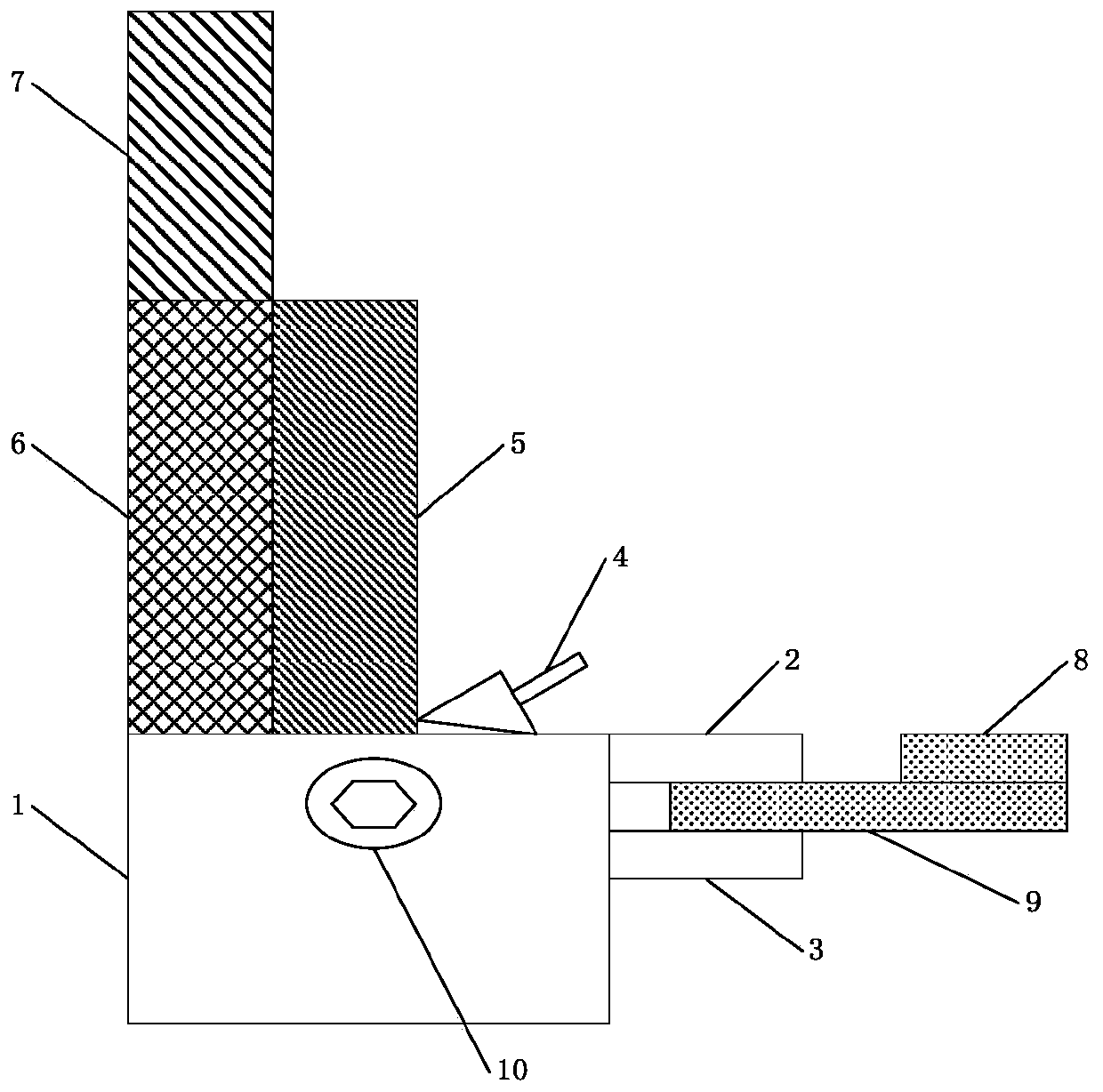

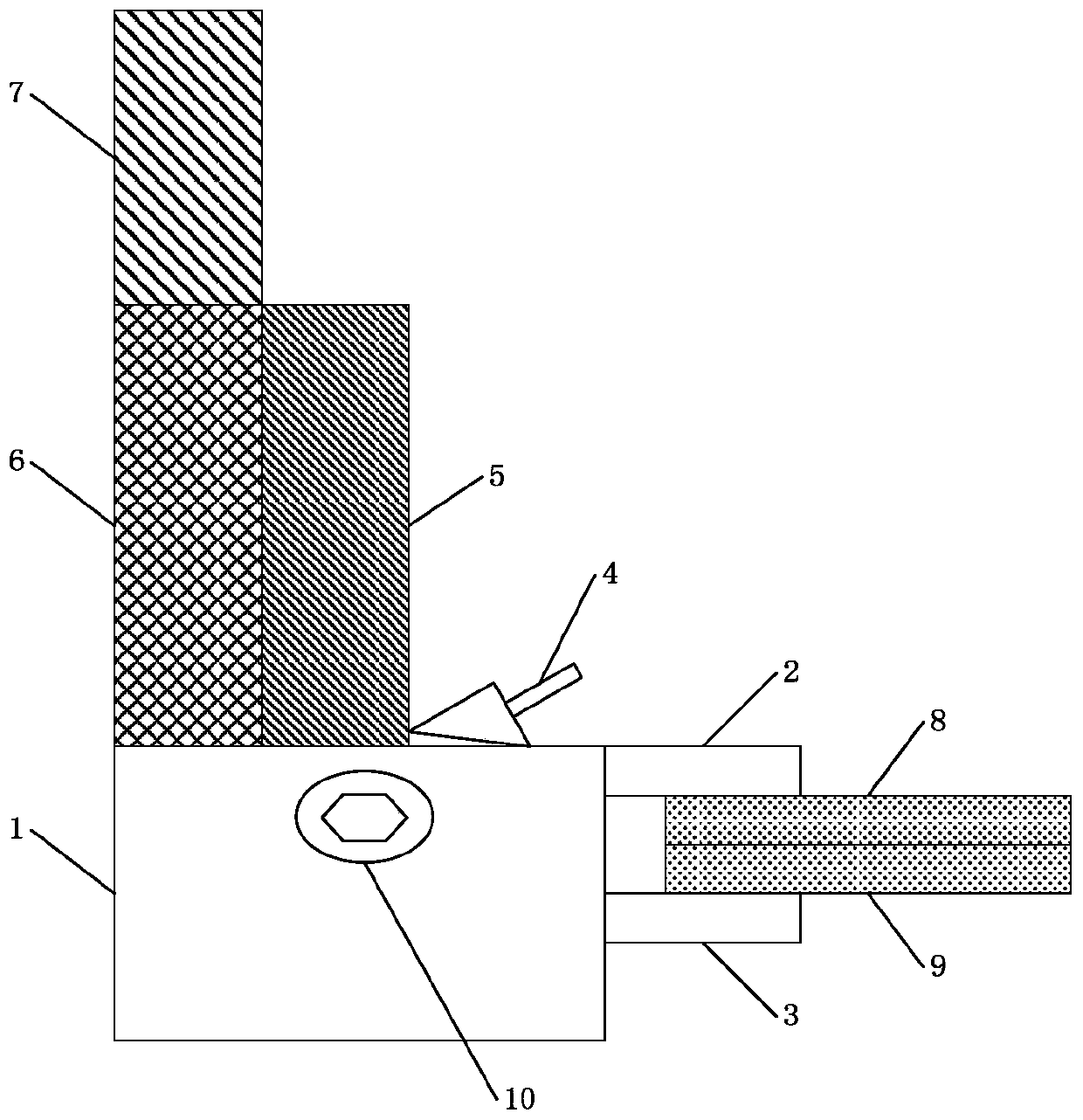

[0036] Such as figure 1 As shown, the working schematic diagram of the existing conveying mechanism Figure 1 , wherein the conveying mechanism includes: a sheet metal block 1, an upper splint 2, a lower splint 3, a set screw 4, a cylinder control device 5, a fixing device 6 and a motor control device 7.

[0037] Wherein the upper splint 2 is connected to the sheet metal block, and the lower splint 3 is connected to the sheet metal block 1 through the connecting shaft 10, so that the upper splint 2, the connecting shaft 10 and the lower splint form a Scissor-like gripping device. The air cylinder control device 5 is arranged on the sheet metal block 1 , and the conveying mechanism controls the upper splint 2 and the lower splint 3 to grip and cut the panel through the air cylinder control device 5 .

[0038] Wherein the set screw 4 is arranged on the sheet metal block 1 , and the conveying mechanism controls the distance between the upper splint 2 and the lower splint 3 thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com