Cobalt removal device for polycrystalline diamond compact and cobalt removal method applying cobalt removal device

A technology of polycrystalline diamond and composite sheet is applied in the field of decobalt device of polycrystalline diamond composite sheet, which can solve the problems of fluctuation, shorten the time of decobalt treatment, and easily corrode the cemented carbide substrate, so as to reduce and improve the sealing requirements. Stability, impact weakening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

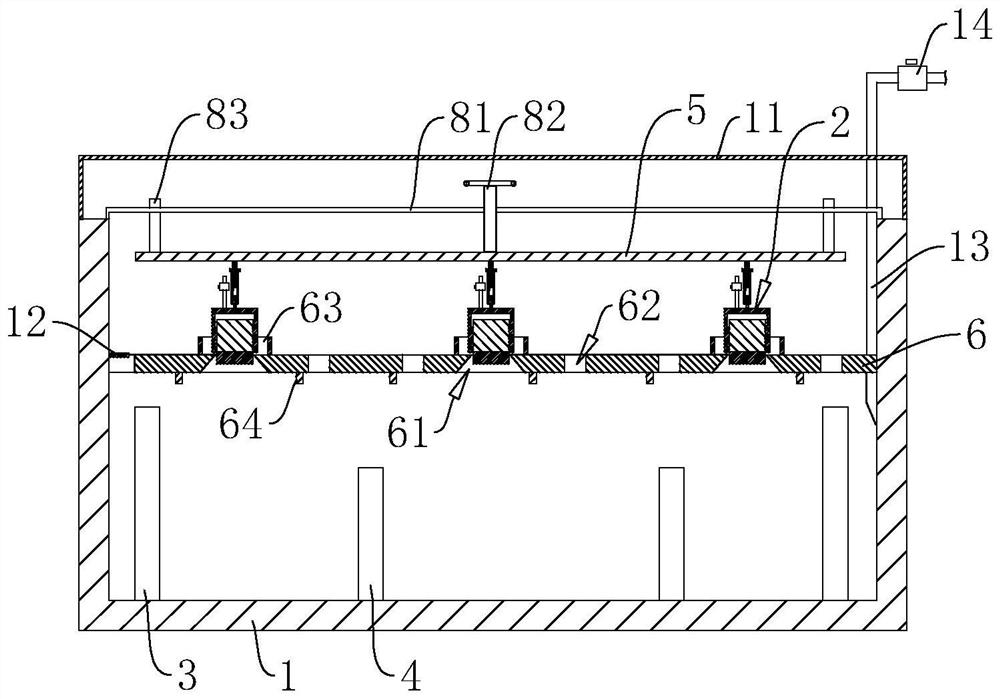

[0058] The embodiment of the present application discloses a decobalt device for a polycrystalline diamond composite sheet. refer to figure 1 , the polycrystalline diamond composite sheet decobalt device includes a solution tank 1 containing a decobalt liquid and a decobalt mold 2. The solution tank 1 is provided with a heating device 3 and a vibration device 4. The heating device 3 can be an electric heating rod, a heat exchange The oscillating device 4 can be an ultrasonic vibrating rod, a stirring rod, etc., but the part extending into the decobalt liquid of the above-mentioned equipment needs to be provided with a corrosion-resistant layer on the outside, such as a PTFE coating or a sheath.

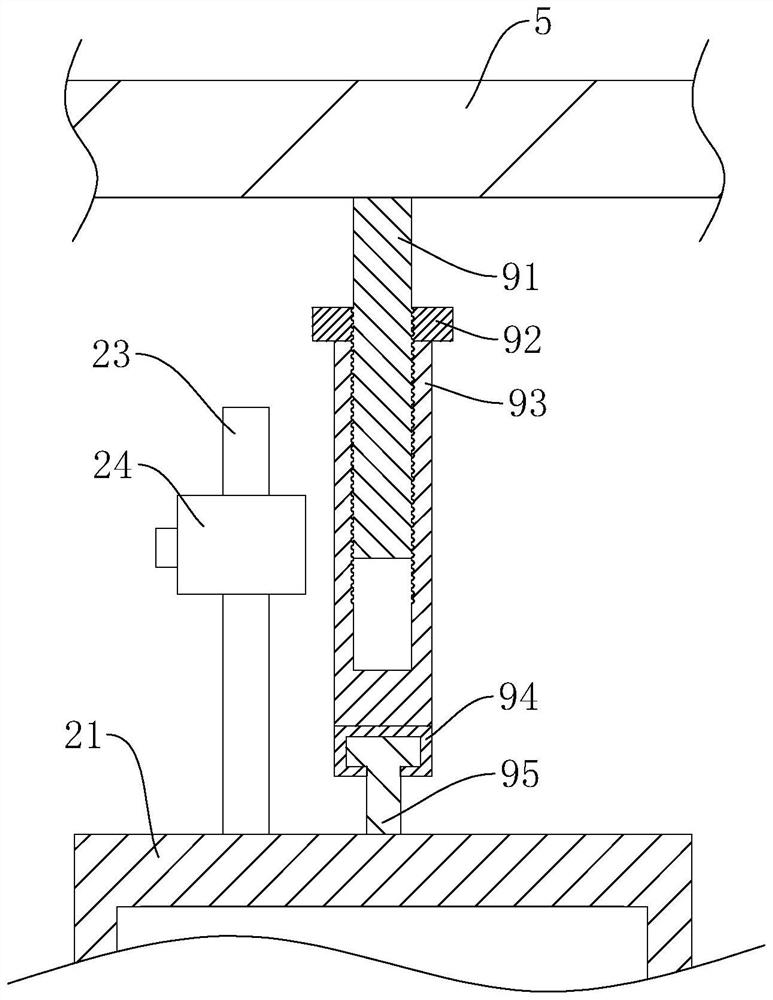

[0059] The solution tank 1 is provided with a deck 5, and the decobalt mold 2 is installed on the deck 5 and the polycrystalline layer of the polycrystalline diamond composite sheet in the decobalt mold 2 is immersed in the decobalt solution of the solution tank 1. A wave suppression...

Embodiment 2

[0086] The embodiment of the present application discloses a decobalt device for a polycrystalline diamond composite sheet. refer to Figure 4 , the difference from Example 1 is that: in order to further reduce the excessive surging phenomenon of the decobalt solution at the through hole 61, the wave suppression cylinder 7 is fixed on the lower end face of the wave suppression plate 6 on the peripheral side of the through hole 61, and the wave suppression cylinder is 7 The inner diameter is larger than the diameter of the through hole 61 . The wave suppression cylinder 7 can be hollowed out as a whole, or only the upper part can be hollowed out, which can not only weaken the excessive flow surging to a certain extent, but also retain the additive effect of the shock effect on reducing the decobalt time as much as possible. Of course, the wave suppressor 7 is also made of a corrosion-resistant material, preferably polytetrafluoroethylene.

[0087] Therefore, in specific imple...

Embodiment 3

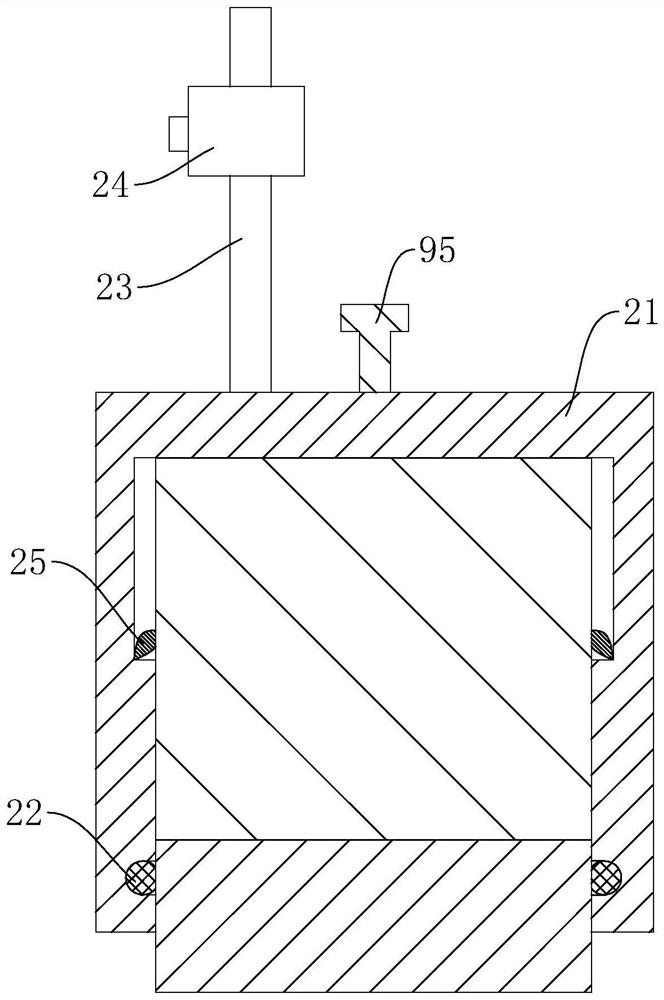

[0089] The embodiment of the present application discloses a decobalt device for a polycrystalline diamond composite sheet. refer to Figure 5 , and the difference from Embodiment 1 is: the mold sleeve 21 is composed of two sections and is divided into an upper section 211 with one end open and a lower section 212 with both ends open, and the adjacent inner walls of the upper section 211 and the lower section 212 are provided with a common accommodating The ring groove 213 of the corrosion-resistant sealing ring 22, and the upper section 211 and the lower section 212 are threadedly connected; at the same time, the lower section 212 is made of corrosion-resistant PTFE, and the upper section 211 can be made of any hard material, such as steel, aluminum alloy , engineering plastics, etc., and the screwed part of the lower section 212 should be wrapped outside the screwed part of the upper section 211; further, the outer wall of the lower section 212 should also be provided with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com