Hyaluronic acid stock solution and preparation method thereof

A technology of hyaluronic acid and mixed solution, which is applied in the fields of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc. It can solve the problems of inability to increase hyaluronic acid hyaluronic acid, etc., achieve strong and long-lasting moisturizing ability, improve regeneration rate, The effect of promoting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

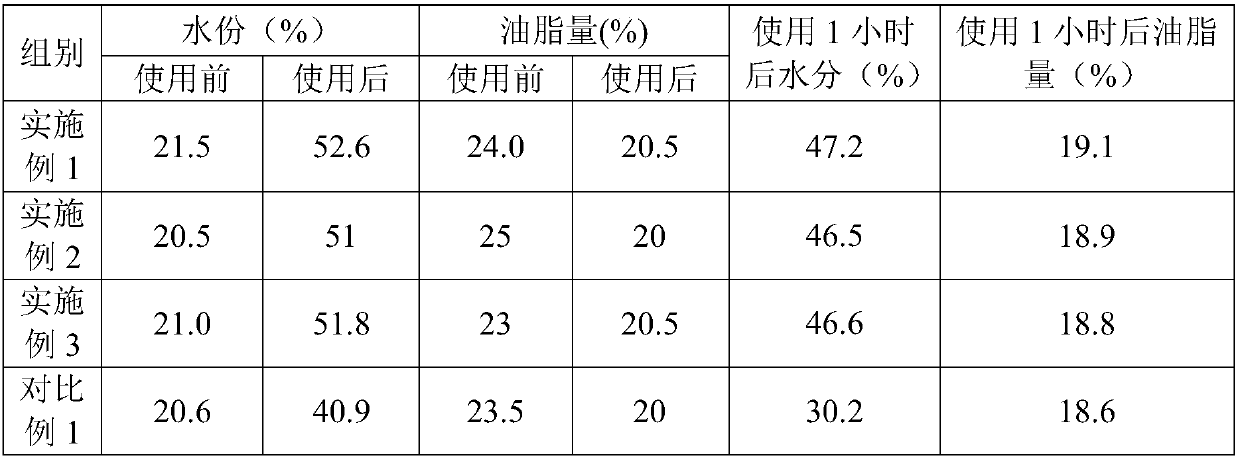

Examples

preparation example Construction

[0037] A preparation method of hyaluronic acid stock solution, comprising:

[0038] Preparation steps of mixed solution A: mix butanediol and p-hydroxyacetophenone in the prescribed amount, heat to 85-90°C, and obtain mixed solution A after dissolving;

[0039] The preparation steps of the mixed solution B: adding the sodium hyaluronate, hydrolyzed chitin and hydroxyethyl cellulose in the formula amount into glycerin, and dispersing evenly to obtain the mixed solution B;

[0040]Preparation steps of mixed liquid C: add the water in the formula amount into the emulsification pot, heat to 85-90°C, then add the mixed liquid A and mixed liquid B, and the formula amount of betaine, and homogenize at a speed of 2000-2500rmp 3 -5min, and then stirred at a speed of 60-70rmp for 20min to obtain a mixed solution C;

[0041] Production steps: Cool down the mixture C to 40°C, add the formula amount of oat-β-glucan, the mixture of sclerotin and phenoxyethanol, 1,2-hexanediol, and stir at ...

Embodiment 1-3

[0048] A hyaluronic acid stock solution, comprising the following components by weight percentage: butylene glycol, glycerin, sodium hyaluronate, hydroxyethyl cellulose, betaine, hydrolyzed chitin, p-hydroxyacetophenone, oat-β-glucan A mixture of sugar, sclerotin and phenoxyethanol, 1,2-hexanediol and purified water (see Table 1 for the specific formula), prepared according to the following method:

[0049] Preparation steps of mixed solution A: mix butanediol and p-hydroxyacetophenone in the prescribed amount, heat to 85°C, and obtain mixed solution A after dissolving;

[0050] Preparation steps of mixed solution B: adding sodium hyaluronate, hydrolyzed chitin and hydroxyethyl cellulose in the prescribed amount into glycerin, and dispersing evenly to obtain mixed solution B;

[0051] Preparation steps of mixed liquid C: Add the water in the formula amount into the emulsification pot, heat to 85°C, then add the mixed liquid A and mixed liquid B, and the formula amount of betai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com