Counter bore type micro-perforated plate applied to water medium, micro-perforated sound absorption structure and sound absorption coefficient calculation method of micro-perforated sound absorption structure

A technology of micro-perforated plate and sound absorption coefficient, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of high sound absorption frequency, long sound wave wavelength, and difficulty in achieving sound absorption effect, and achieve good adaptability, easy processing, and calculation results Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

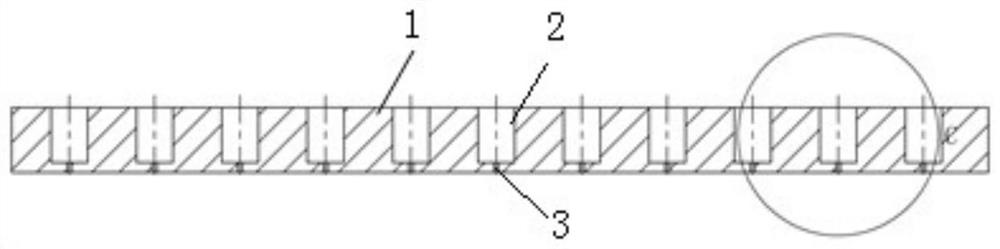

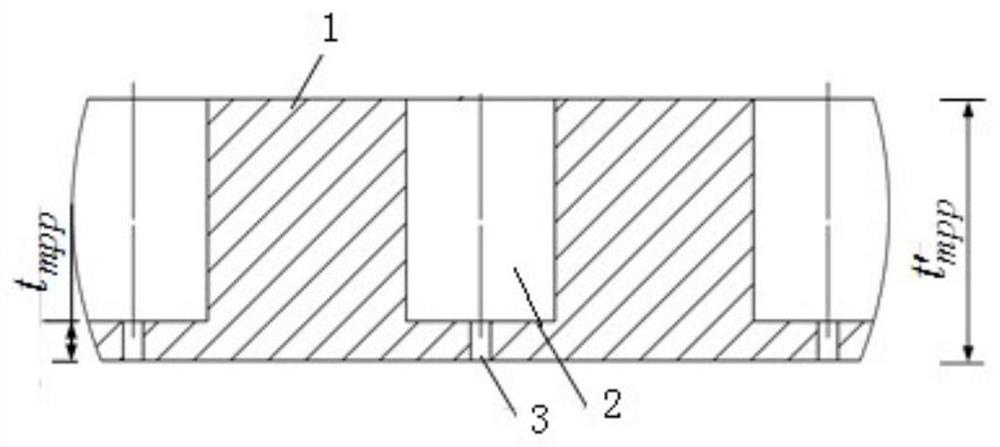

[0060] see figure 1 , figure 2 with Figure 4 The counterbore micro-perforated plate of the present invention includes a plate body 1, and a plurality of through-hole perforation units are opened on the plate body 1. Microperforations with connected bottoms3. The plate body 1 is made of stainless steel or cupronickel; preferably, considering the machinability, the diameter of the counterbore is not less than 1mm, and the depth of the counterbore 2 is 5-20mm; the diameter of the micro-perforation is 0.02 -0.4mm. The bottom surface of counterbore 5 is plane in the present embodiment, see image 3 , according to the needs of processing, the bottom surface of the counterbore 5 can also be a tapered surface;

[0061] The microperforations 3 on the same plate body have the same or different hole diameters and the same or different hole depths. In this example figure 1 The hole depth and diameter of the micro-perforation 3 are the same, Figure 4 The micro-perforated holes 3...

Embodiment 2

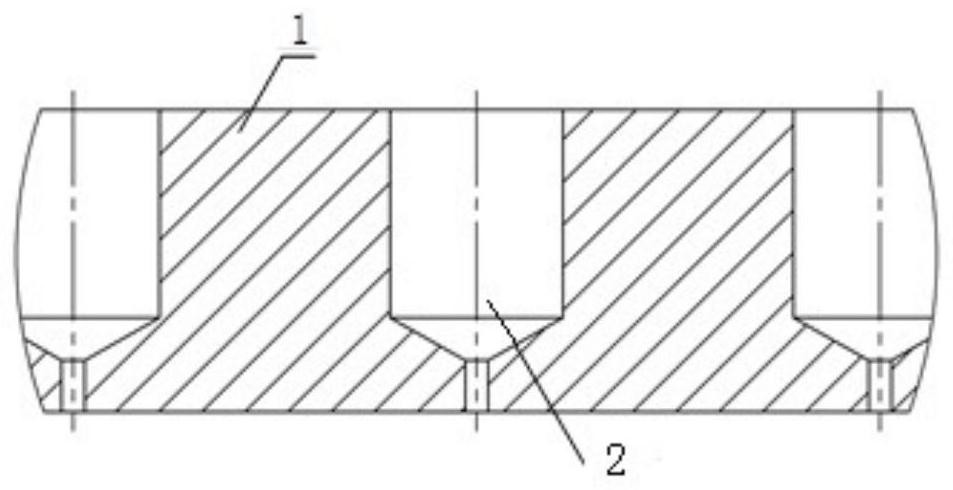

[0063] see Figure 5 , in this embodiment, the perforation unit includes corresponding upper sinkholes 2.1 and lower sinkholes 2.2 located on both sides of the plate body, and micro-perforation holes 3 whose two ends communicate with the bottoms of the upper and lower sinkholes 2.1 and 2.2 respectively. All the other are with embodiment 1.

Embodiment 3

[0065] see Image 6 , In this embodiment, the micro-perforations described in this embodiment have two different hole depths, and the rest are the same as in Embodiment 1.

[0066] Example 1 of micro-perforated sound-absorbing structure applied in water medium:

[0067] see Figure 7 The sound absorbing structure of the present invention consists of the counterbore micro-perforated plate 4 and the back plate 6 described in Embodiment 1, and the cavity structure 7 surrounded by the side plates 5 is between the counter-hole micro-perforated plate 4 and the back plate 6 , the preferred backplane thickness is 0.2-10mm.

[0068] Calculation method of sound absorption coefficient of micro-perforated sound-absorbing structure in water medium:

[0069] The equivalent circuit of the sound-absorbing structure of the micro-perforated plate was established by using the acoustic-electric analogy method (such as Figure 8 shown), wherein the micro-perforated plate is connected in series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com