Polyurethane sound-absorbing cotton and preparation method thereof

A sound-absorbing cotton and polyurethane technology, applied in the chemical industry, can solve the problems of easy deformation, narrow sound-absorbing frequency range, and easy aging, and achieve stable chemical and physical properties, wide sound-absorbing frequency range, and excellent sound-absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Made from A component and B component according to the following parts by weight:

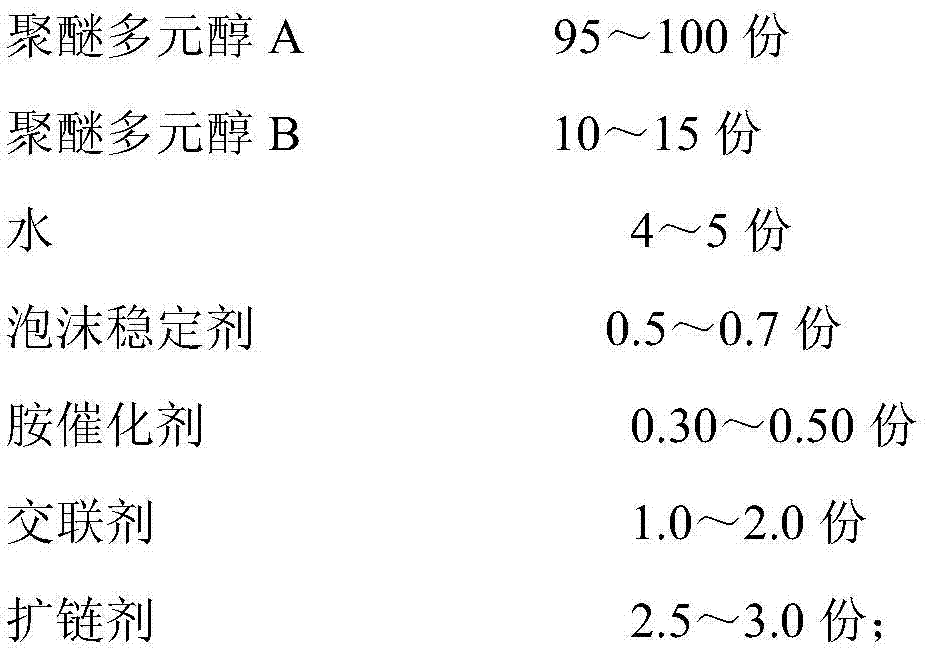

[0031] A component:

[0032]

[0033] B component:

[0034] 37 parts of modified black material;

[0035] in:

[0036] The modified black material is a modified black material with an NCO content of 28.5% prepared by reacting polyether polyol with trifunctionality and molecular weight of 700 and black material PM200 at a mass ratio of 3:3.6 at 85°C for 3 hours.

[0037] Its preparation method comprises the following steps:

[0038] Put the raw materials of component A into the mixer and mix evenly, adjust the constant material temperature to 25±2°C, adjust the speed of the agitator to 4500r / min, pour component B preheated to 25±2°C into component A and stir for 20s , Pour the mixed material into a mold preheated to 40±5°C, and demould after 8 minutes to obtain the product.

[0039] The product prepared in embodiment 1 is subjected to a performance test, and the test results are a...

Embodiment 2

[0045] Made from A component and B component according to the following parts by weight:

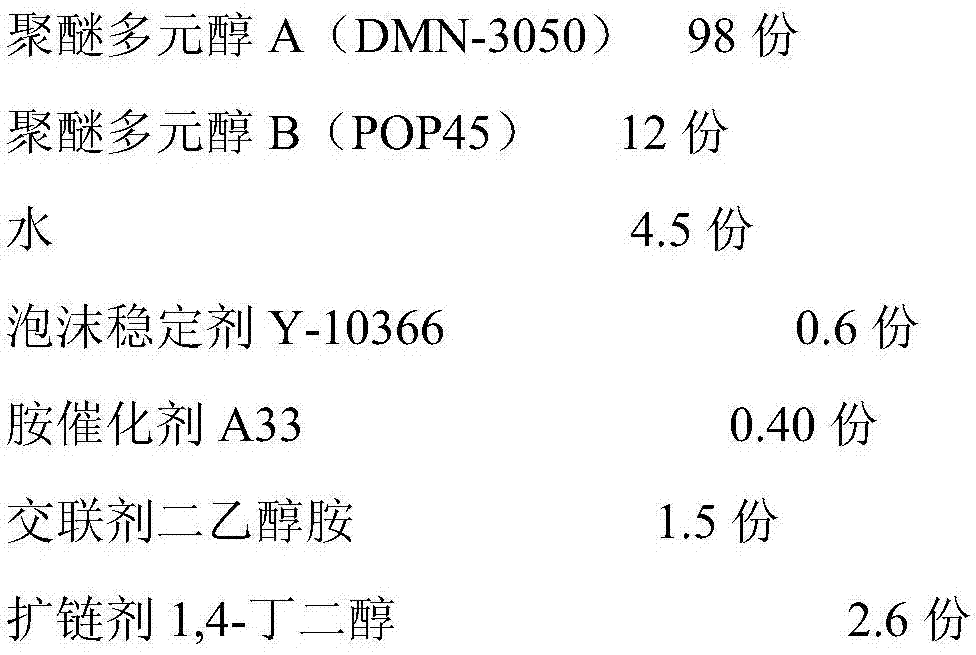

[0046] A component:

[0047]

[0048]

[0049] B component:

[0050] 40 parts of modified black material;

[0051] in:

[0052] The modified black material is a modified black material with an NCO content of 28.5% prepared by reacting polyether polyol with trifunctionality and molecular weight of 700 and black material PM200 at a mass ratio of 3:3.6 at 85°C for 3 hours.

[0053] Its preparation method comprises the following steps:

[0054] Put the raw materials of component A into the mixer and mix evenly, adjust the constant material temperature to 25±2°C, adjust the speed of the agitator to 5000r / min, pour component B preheated to 25±2°C into component A and stir for 15s , Pour the mixed material into a mold preheated to 40±5°C, and demould after 5 minutes to obtain the product.

[0055] The product prepared in embodiment 2 is subjected to a performance test, and the test r...

Embodiment 3

[0061] Made from A component and B component according to the following parts by weight:

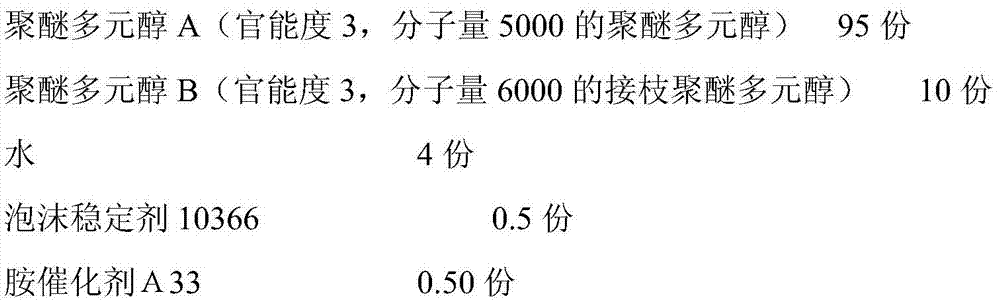

[0062] A component:

[0063]

[0064] B component:

[0065] 35 parts of modified black material;

[0066] in:

[0067] The modified black material is a modified black material with an NCO content of 28.5% prepared by reacting polyether polyol with trifunctionality and molecular weight of 700 and black material PM200 at a mass ratio of 3:3.6 at 85°C for 3 hours.

[0068] Its preparation method comprises the following steps:

[0069] Put the raw materials of component A into the mixer and mix evenly, adjust the constant material temperature to 25±2°C, adjust the speed of the agitator to 4000r / min, pour component B preheated to 25±2°C into component A and stir for 25s , Pour the mixed material into a mold preheated to 40±5°C, and demould after 10 minutes to obtain the product.

[0070] The product prepared in embodiment 3 is subjected to a performance test, and the test results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com