Sound absorption metamaterial with adjustable sound absorption performance and additive manufacturing method thereof

An additive manufacturing and metamaterial technology, applied in the field of acoustic metamaterials, can solve problems such as difficult adjustment and poor adaptability to environmental conditions, and achieve the effects of good movement, ensuring no leakage of sound waves, and good sound absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

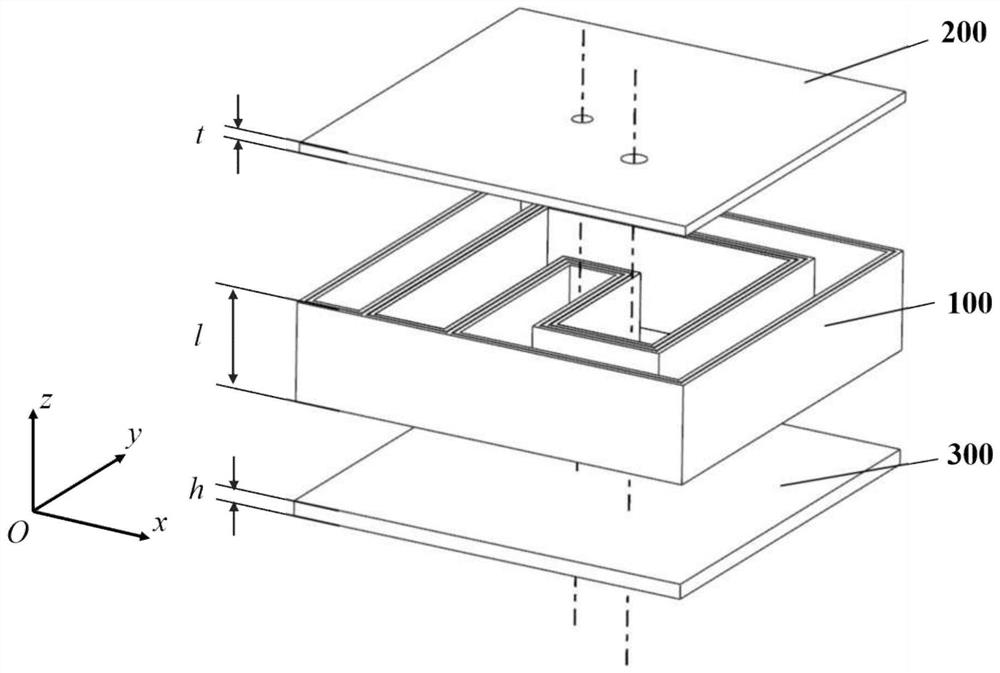

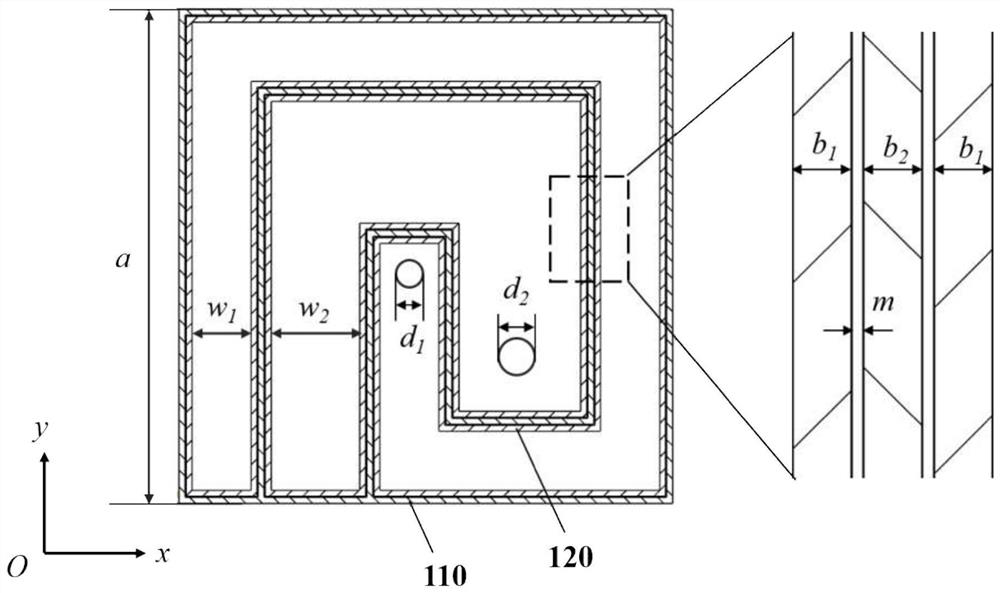

[0041] When designing the structure of sound-absorbing metamaterials with adjustable sound-absorbing performance, it is first necessary to determine the sound-absorbing effect, and then determine the specific size parameters. There are many size parameters of sound-absorbing metamaterials, some of which have little effect on sound-absorbing performance (such as frame thickness, back plate thickness, etc.), and some have a greater impact on sound-absorbing performance (such as micropore diameter, micro-perforated plate thickness, acoustic channel length, etc.). Since the sound-absorbing metamaterial proposed in the present invention can realize the dynamic adjustment of the depth of the sound channel, it is first necessary to fix other dimensional parameters, and then adjust the sound-absorbing performance by stretching. Specific steps are as follows:

[0042] (1) The determination of the parameters needs to consider the constraints of the specific manufacturing process. For t...

Embodiment 2

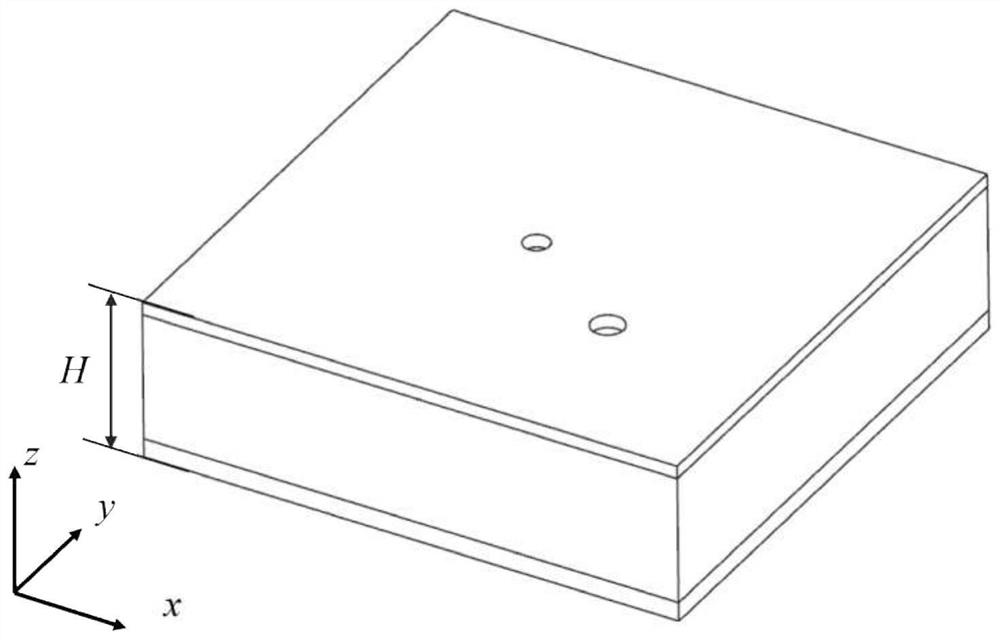

[0048] (1) First determine the parameter value that has little influence on the sound absorption effect: take the thickness h of the back plate as 1.5mm, the thickness of the frame and the internal partition are both 0.5mm, and the gap between the frame and the internal partition is 0.1mm, Therefore, the distance between two adjacent sound channels is 1.7mm.

[0049] (2) Determine the parameter values that have a greater impact on the sound absorption effect. The external dimension of the curling unit is 42mm, the depth of the sound channel is 10mm, the number of bending times of the first sound channel is 5 times, the number of bending times of the second sound channel is 3 times, and the width of the first sound channel is w 1 is 5mm, the width w of the second sound channel 2 According to the quantitative relationship, it can be obtained as 9mm. The aperture d of the microperforated plate 200 1 and d 2 2mm and 2.5mm respectively.

[0050] (3) Siemens NX 10.0 three-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com