Straight-column type lattice-enhanced mixed underwater sound absorption structure

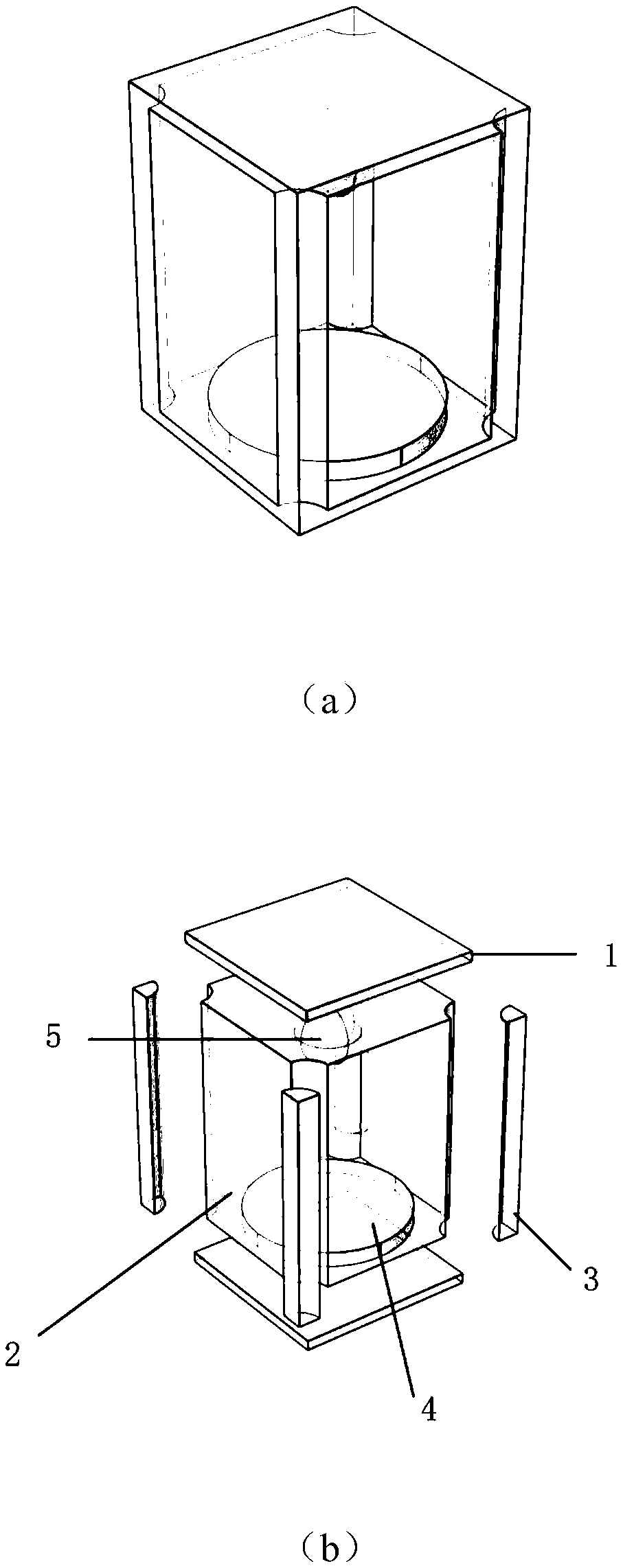

A mixed-type and straight-column technology, applied in the direction of sound-generating devices and instruments, to achieve excellent sound-absorbing performance, lightweight design, and good water pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

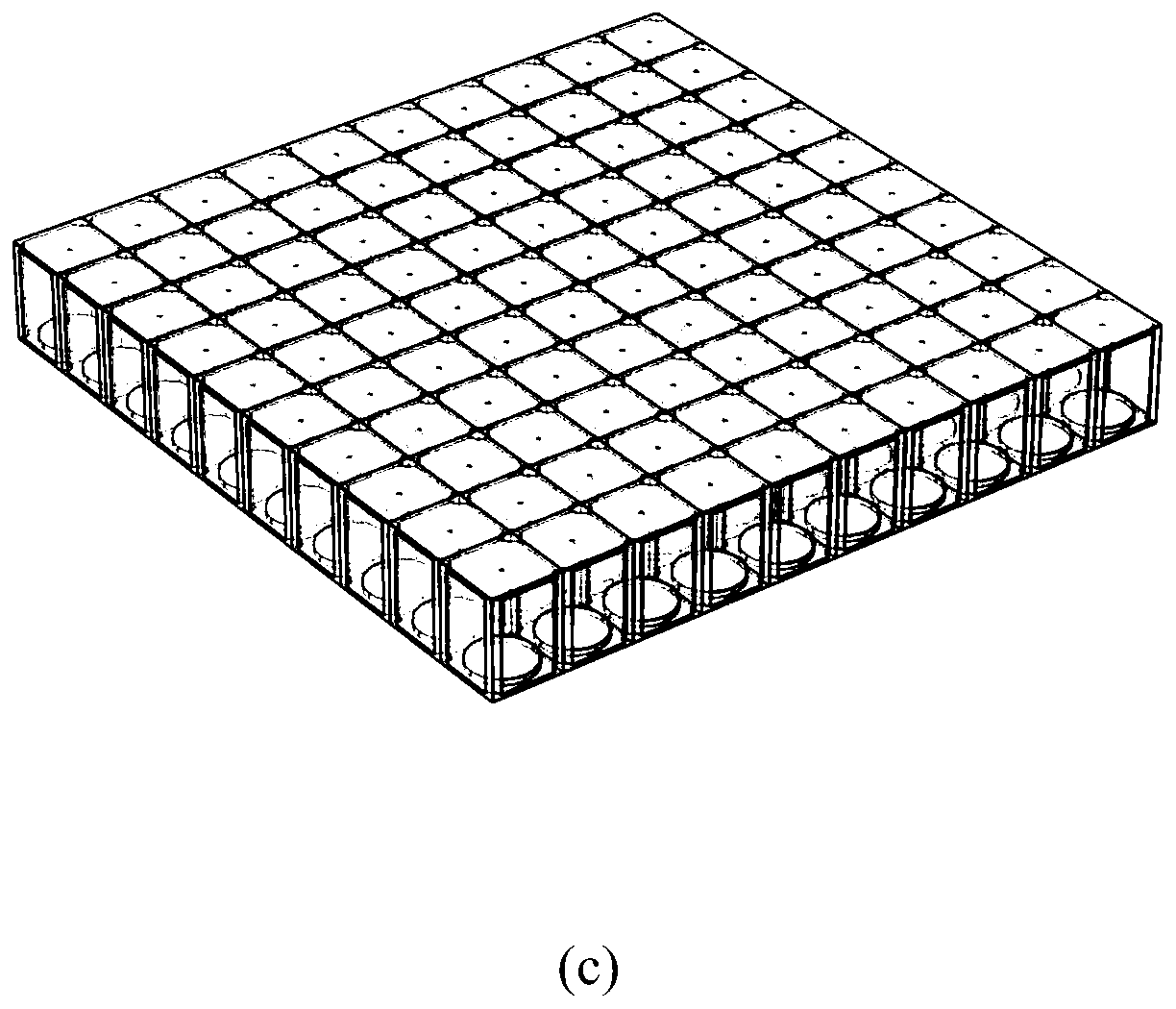

[0063] Examples of materials:

[0064] Carbon fiber: Density 1450kg / m3, Young's modulus 80GPa, Poisson's ratio 0.1, equivalent isotropic loss factor 0.

[0065] Rubber: Density 1500kg / m3, Young's modulus 15MPa, Poisson's ratio 0.49, equivalent isotropic loss factor 0.6.

[0066] Steel: Density 7850kg / m 3 , Young's modulus 200GPa, Poisson's ratio 0.3, equivalent isotropic loss factor is 0.

[0067] Water: Density 1000kg / m3, sound velocity 1500m / s.

[0068] Air: Density 1.29kg / m3, sound velocity 343m / s.

[0069] The structure size of embodiment:

[0070] The side length of the cell is 36mm, the thickness of the panel is 2mm, the thickness of the damping layer is 46mm, the radius of the rod is 4.5mm, the height of the cavity is 3mm, the radius of the cavity is 16mm, the radius of the local resonator is 6mm, and the distance between the local resonator and the lower surface of the upper panel is 0.1mm.

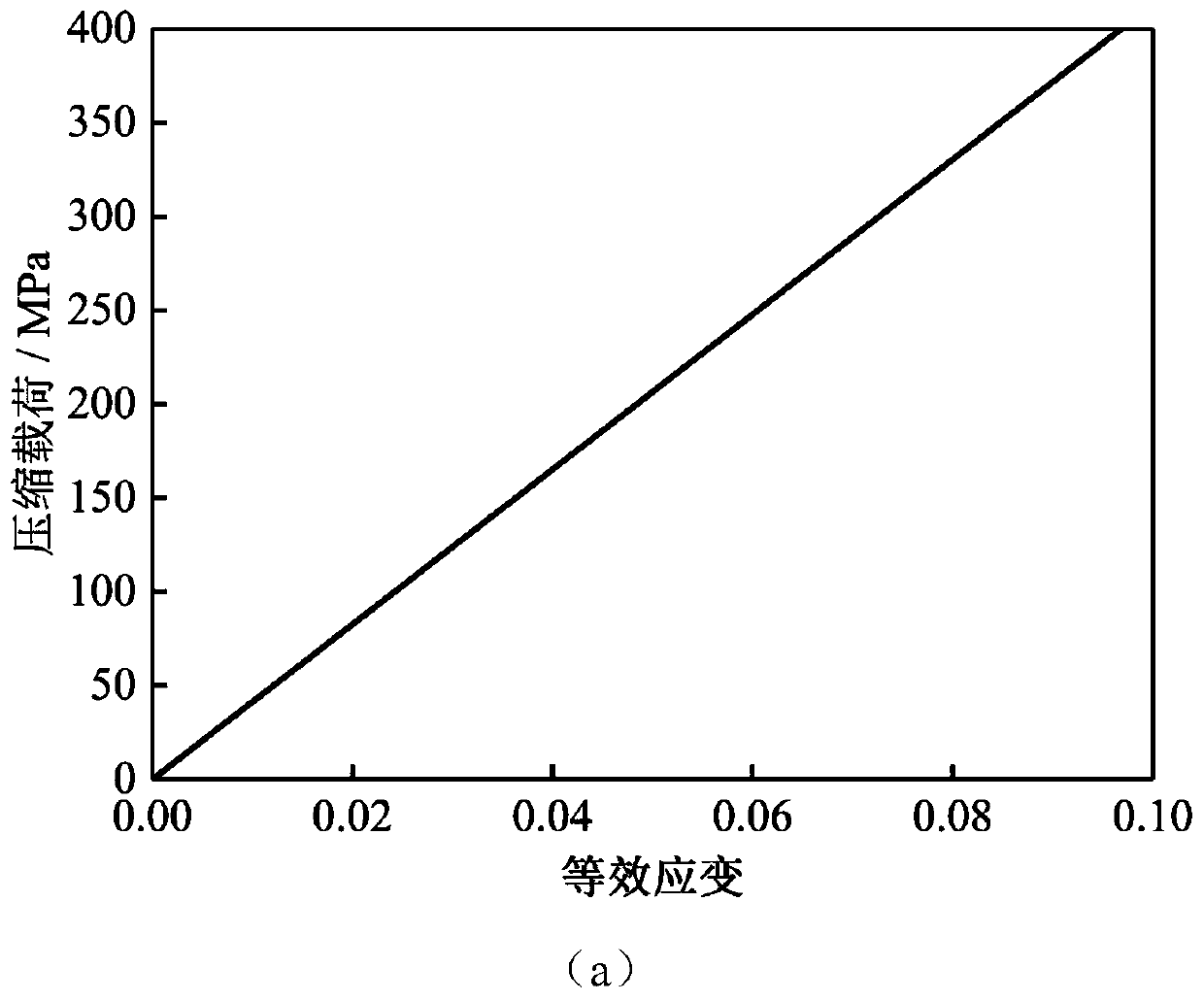

[0071] Using the above materials and structural dimensions to carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com