Structure improving low frequency sound absorption performance through magnetism

A low-frequency, sound-absorbing technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of reducing the damping coefficient, reducing the elastic coefficient of mechanical impedance, etc., to achieve the effect of reducing the elastic coefficient, improving the low-frequency sound absorption performance, and good viscous damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

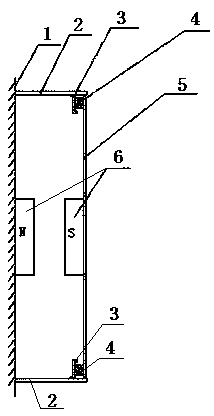

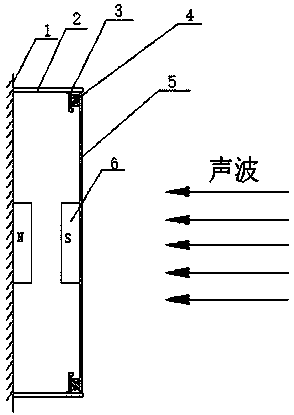

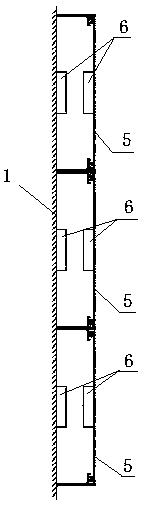

[0018] See figure 1 , Two transverse brackets 2 perpendicular to the wall 1 are fixedly installed on the wall 1. The two brackets 2 have the same structure and are parallel to each other. A mechanical impedance board 5 parallel to the wall 1 is arranged between the two transverse supports 2, and the mechanical impedance board 5 is parallel to the wall 1 with a certain distance therebetween. A square resonant cavity is enclosed between a mechanical impedance plate 5, two lateral supports 2 and the wall 1. A pair of magnetic material blocks 6 are arranged inside the square resonant cavity, and one of the magnetic material blocks 6 is a magnetic material. The block is fixedly connected to the wall 1, and the other one of the pair of magnetic material blocks 6 is fixedly connected to the mechanical impedance board 5. That is, a pair of magnetic material blocks 6 are located between the wall 1 and the mechanical impedance plate 5. The two magnetic material blocks of the pair of magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com