A kind of preparation method of low-frequency sound-absorbing material

A sound-absorbing material and low-frequency technology, which is applied in the field of preparation of low-frequency sound-absorbing materials, can solve the problems that the sound-absorbing performance of metal fiber porous materials cannot be exerted normally, changing porous materials, and poor sound-absorbing performance at low frequencies, etc., to achieve sound-absorbing performance Excellent, improved low-frequency sound absorption performance, and the effect of improving sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

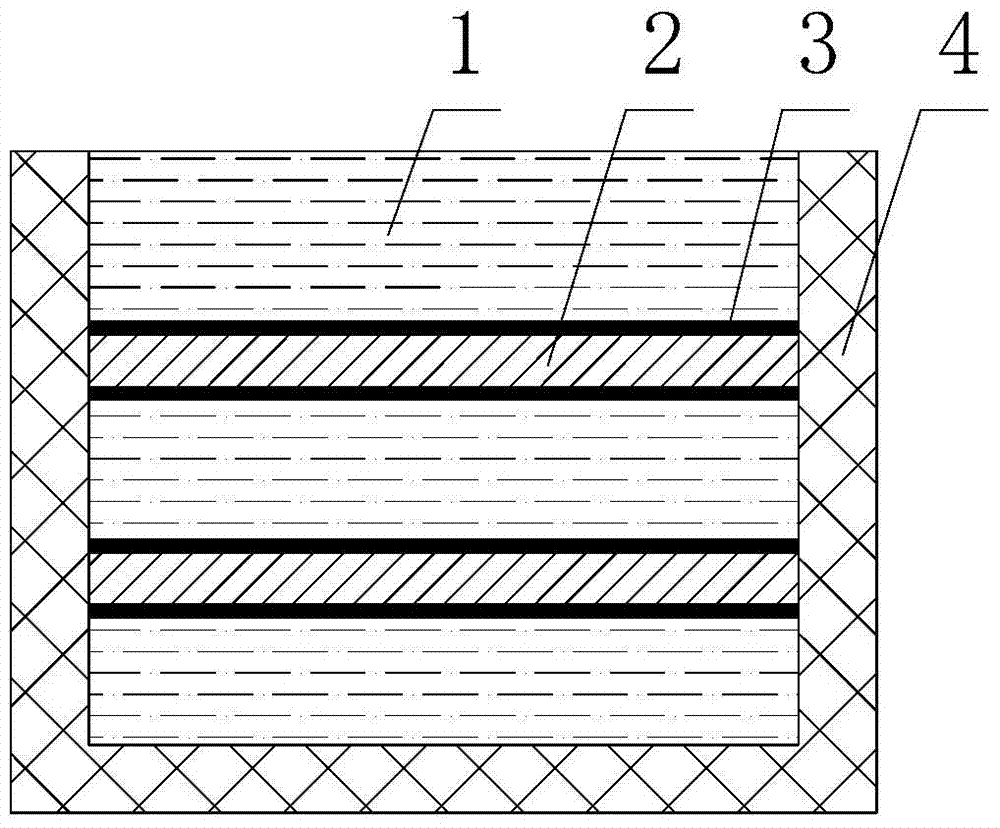

[0030] The preparation method of the low-frequency sound-absorbing material of this embodiment comprises the following steps:

[0031] Step 1. Mix the aluminum powder with an average particle size of 30 μm and the polyvinyl alcohol aqueous solution with a mass percentage concentration of 5% to obtain a slurry 3. The mass percentage of the aluminum powder in the slurry 3 is 10%, and then the The slurry 3 is evenly coated on the upper and lower surfaces of the aluminum foil 2 with a thickness of 0.4 mm, and the coating thickness is 20 μm;

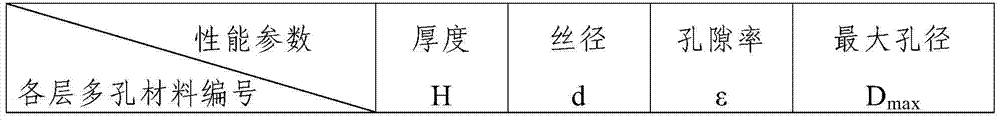

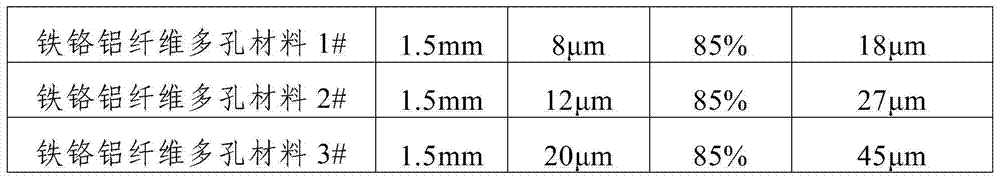

[0032] Step 2, select the multi-layer iron-chromium-aluminum fiber porous material 1, the maximum pore diameter D of the iron-chromium-aluminum fiber porous material 1 in each layer max are not the same, the D max Satisfy: Where d is the wire diameter of FeCrAl fiber in FeCrAl fiber porous material 1, ε is the porosity of FeCrAl fiber porous material 1, D max The units of and d are both μm; the number of layers of the multilayer Fe-Cr-Al ...

Embodiment 2

[0040] The preparation method of the low-frequency sound-absorbing material of this embodiment comprises the following steps:

[0041] Step 1. Mix the aluminum powder with an average particle size of 40 μm and the polyvinyl alcohol aqueous solution with a mass percentage concentration of 4% to obtain a slurry 3. The mass percentage of the aluminum powder in the slurry 3 is 15%, and then the The slurry 3 is evenly coated on the upper and lower surfaces of the aluminum foil 2 with a thickness of 0.25 mm, and the coating thickness is 30 μm;

[0042] Step 2, select the multi-layer iron-chromium-aluminum fiber porous material 1, the maximum pore diameter D of the iron-chromium-aluminum fiber porous material 1 in each layer max are not the same, the D max Satisfy: Where d is the wire diameter of FeCrAl fiber in FeCrAl fiber porous material 1, ε is the porosity of FeCrAl fiber porous material 1, D maxThe units of and d are both μm; the number of layers of the multilayer Fe-Cr-Al ...

Embodiment 3

[0049] The preparation method of the low-frequency sound-absorbing material of this embodiment comprises the following steps:

[0050] Step 1, uniformly mixing aluminum powder with an average particle size of 20 μm and 3% polyvinyl alcohol aqueous solution to obtain slurry 3, wherein the mass percent of aluminum powder in the slurry 3 is 20%, and then The slurry 3 is evenly coated on the upper and lower surfaces of the aluminum foil 2 with a thickness of 0.1 mm, and the coating thickness is 10 μm;

[0051] Step 2, select the multi-layer iron-chromium-aluminum fiber porous material 1, the maximum pore diameter D of the iron-chromium-aluminum fiber porous material 1 in each layer max are not the same, the D max Satisfy: Where d is the wire diameter of FeCrAl fiber in FeCrAl fiber porous material 1, ε is the porosity of FeCrAl fiber porous material 1, D max The units of and d are both μm; the number of layers of the multilayer iron-chromium-aluminum fiber porous material 1 se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com