A kind of composite foam with hierarchical porous structure and its preparation method and use

A graded porous and composite foam technology, which is applied in the direction of instruments and sound-generating devices, can solve the problems that the sound absorption performance of melamine foam does not fully meet the actual needs, and achieve the effect of improving the low-frequency sound absorption effect and improving the sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

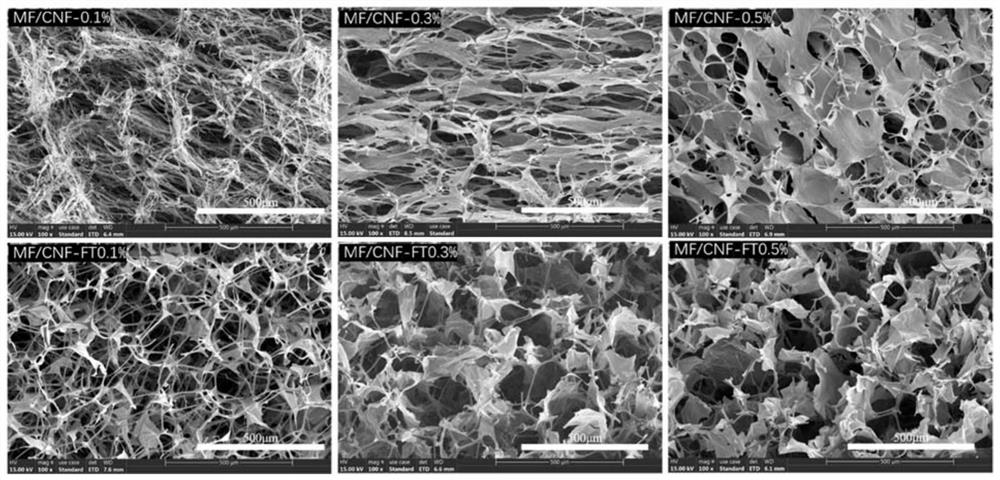

[0055] Embodiment 1, the preparation of the composite foam with hierarchical porous structure of the present invention

[0056] Put 3.906g nanocellulose aqueous solution (CNF solution, the nanocellulose content is 0.512wt% in the nanocellulose aqueous solution used) and 16.094g deionized water in the beaker of 30mL and stir, obtain the CNF concentration of 0.1wt % of the mixture. The MF foam was cut into cylinders with a diameter of 29 mm and a thickness of 2 cm with a router. Put the MF foam into the mixture, press it three times with a long glass stopper to obtain the mixture, then place the obtained mixture in a water bath ultrasonic machine for 1 hour of ultrasonication; the samples obtained after ultrasonication undergo 4 cycles of freezing, which are stored at -20°C Freeze for 15h, then take out the sample and place it at room temperature to thaw for 9h as a cycle, then freeze the obtained mixture for 10min with liquid nitrogen, then place it in a freeze dryer for 72h, ...

Embodiment 2

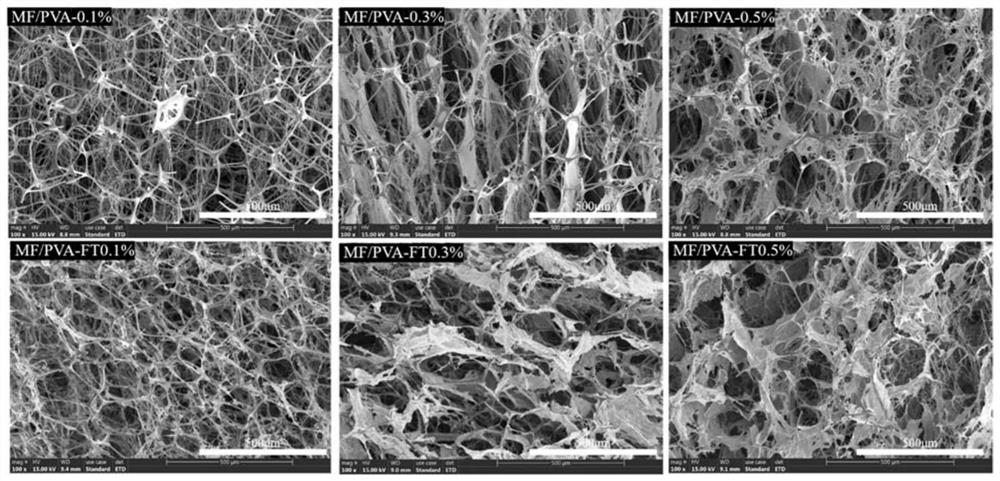

[0062] Embodiment 2, the preparation of the composite foam with hierarchical porous structure of the present invention

[0063] Put 0.420g polyvinyl alcohol aqueous solution (PVA solution, PVA content is 4.762wt% in the PVA solution used) and 19.580g deionized water in the beaker of 30mL and stir evenly, obtain the mixed solution that PVA concentration is 0.1wt% . The MF foam was cut into cylinders with a diameter of 29 mm and a thickness of 2 cm with a router. Put the MF foam into the mixture, press it three times with a long glass stopper to obtain the mixture, then place the obtained mixture in a water bath ultrasonic machine for 1 hour of ultrasonication; the samples obtained after ultrasonication undergo 4 cycles of freezing, which are stored at -20°C Freeze for 15h, then take out the sample and place it at room temperature to thaw for 9h as a cycle, then freeze the obtained mixture for 10min with liquid nitrogen, then place it in a freeze dryer for 72h, to obtain the me...

Embodiment 3

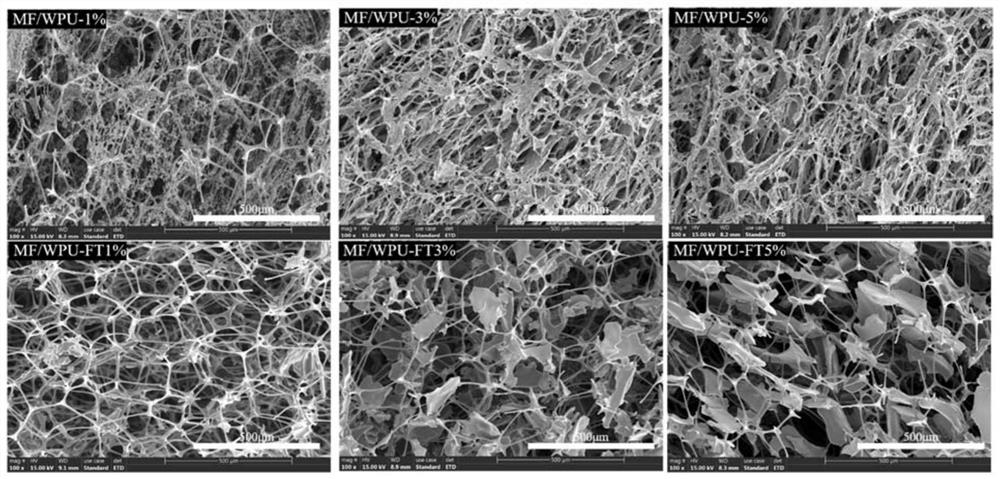

[0067] Embodiment 3, the preparation of the composite foam with hierarchical porous structure of the present invention

[0068] Put 0.4g water-soluble polyurethane aqueous solution (WPU solution, WPU content is 50wt% in the WPU solution used) and 19.6g deionized water in the beaker of 30mL and stir evenly, obtain the mixed solution that WPU concentration is 1wt%. The MF foam was cut into cylinders with a diameter of 29 mm and a thickness of 2 cm with a router. Put the MF foam into the mixture, press it three times with a long glass stopper to obtain the mixture, then place the obtained mixture in a water bath ultrasonic machine for 1 hour of ultrasonication; the samples obtained after ultrasonication undergo 4 cycles of freezing, which are stored at -20°C Freeze for 15h, then take out the sample and place it at room temperature to thaw for 9h as a cycle, then freeze the obtained mixture for 10min with liquid nitrogen, then place it in a freeze dryer for 72h, to obtain the mela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com