Light and thin low-frequency sound absorption material and preparation method and application thereof

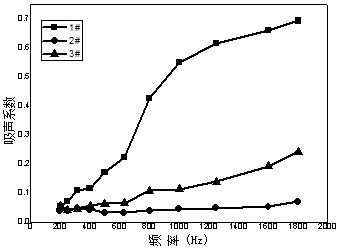

A sound-absorbing material and low-frequency technology, which is applied in chemical instruments and methods, transportation and packaging, and final product manufacturing, can solve the problems of low porosity of woven fabrics, small thickness of woven fabrics, and poor sound absorption performance, and achieve low-frequency absorption Good sound effect, light weight, and the effect of improving low-frequency sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The hollow polyester yarn is warped, drawn in, weaved, and the fabric structure diagram and the upper machine diagram are changed to obtain the bark crepe woven fabric and the honeycomb woven fabric respectively; the polypropylene fiber is opened, carded, and formed into a net. Acupuncture and reinforcement to obtain polypropylene needle-punched nonwovens; polyester yarns are warped, threaded, and woven to obtain polyester warp-knitted fabrics; polyurethane foam is quickly passed through a propane gas flame burning at 1300-1500 ° C to make it The upper and lower surfaces are heated, and the polyester warp-knitted fabric and polypropylene non-woven fabric are placed on the upper and lower sides of the polyurethane foam, pressurized by a roller, and cooled to obtain a flame-melted layer of polyester warp-knitted fabric / polyurethane foam / polypropylene non-woven fabric Pressed fabric composite material; the woven fabric and composite material are laminated by yarn stitching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com