Gradient slitting double-porosity sound absorbing device and application thereof

A sound-absorbing device and double-porosity technology, which is applied in the directions of sound-producing equipment, instruments, floors, etc., to achieve the effect of enhancing low-frequency sound absorption performance, good sound absorption performance, and excellent sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

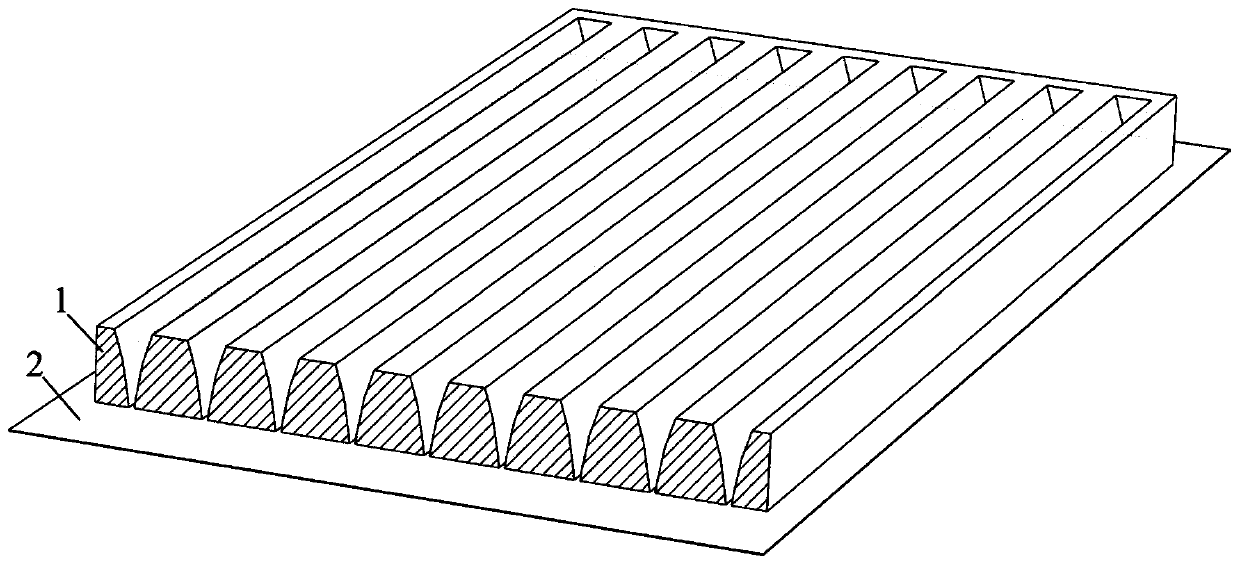

[0043] see figure 1 and figure 2 , periodically open gradient slots in a perforated porous material plate 1 with a total height of 60mm, the porosity of the base porous material is 90%, and the flow resistance is 47700N·s / m 2 , the viscous characteristic length is 24 μm, the thermal characteristic length is 200 μm, and the tortuosity is 1.29; the slit widths at both ends of the gradient slit are 22 mm and 2 mm respectively, the slit type is trumpet-shaped, the slit edge is an arc, and the slope of the slit edge is in the presence of sound waves Continuously increasing in the direction, the slit rate on the sound-absorbing panel (the total volume of slits accounted for the total volume of the panel without slits) is 16.68%; the side of the end face with the smallest slit width of the perforated porous material plate 1 is placed on the rigid backing In order to simulate the situation where the designed sound-absorbing material is attached to the interior wall, the wall of the ...

Embodiment 2

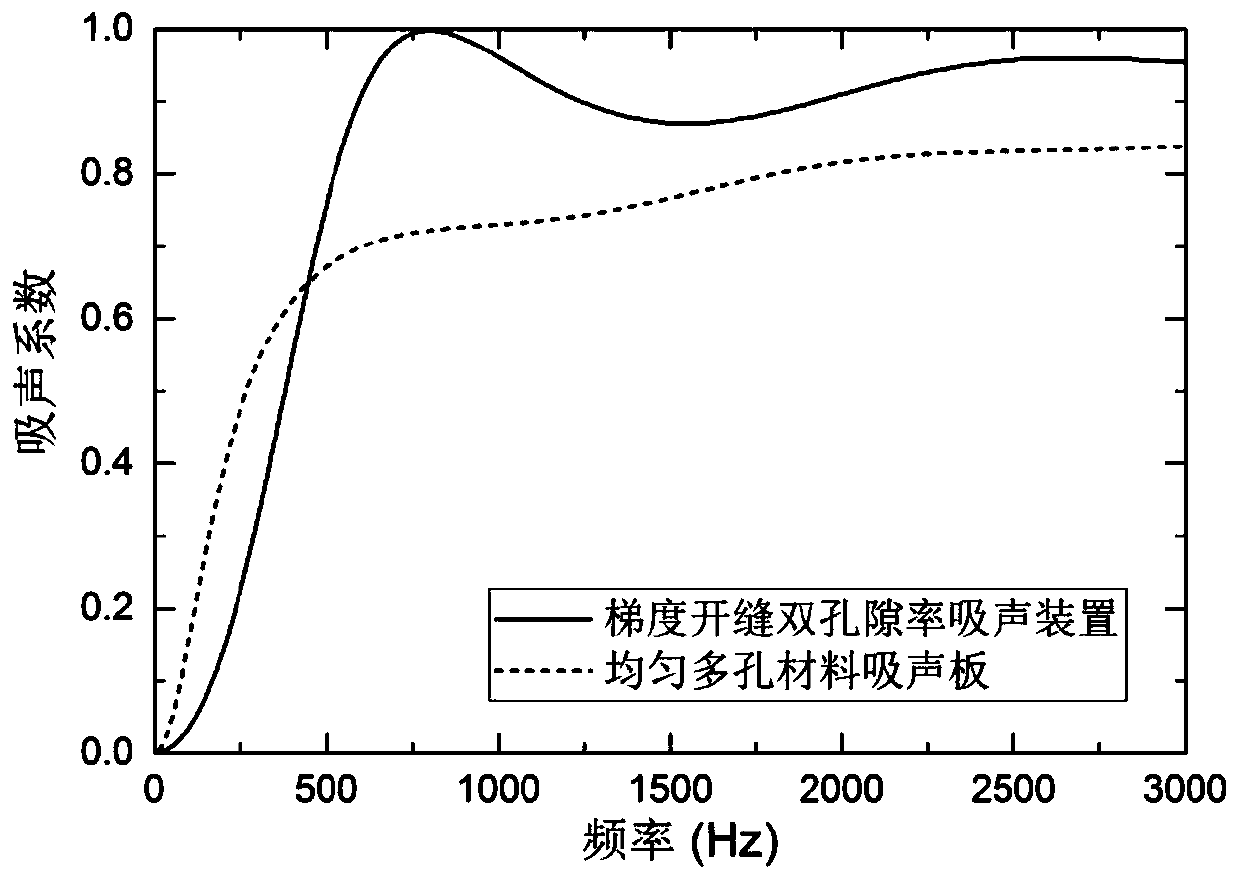

[0046] The trumpet-shaped seam in Example 1 is changed to a tapered seam, the seam edge is a straight line, and the slope of the seam edge remains unchanged in the direction of sound wave incidence, while the seam width and other structural parameters at both ends of the gradient seam, and the porous material of the substrate The material parameters remain unchanged relative to Example 1. At this time, the slit rate of the sound-absorbing panel is 24%; The sound-absorbing material is closely attached to the indoor wall, the wall of the transportation vehicle and the inner wall of the machine. The sound absorption coefficient of embodiment 2 is referring to image 3 . Compared with a uniform porous material plate without slits of the same base material and the same thickness, the structure of this embodiment can appear the sound absorption peak earlier at the frequency of 960 Hz, and achieve enhanced sound absorption in the range above 580 Hz.

[0047] Comparing Example 1 and...

Embodiment 3

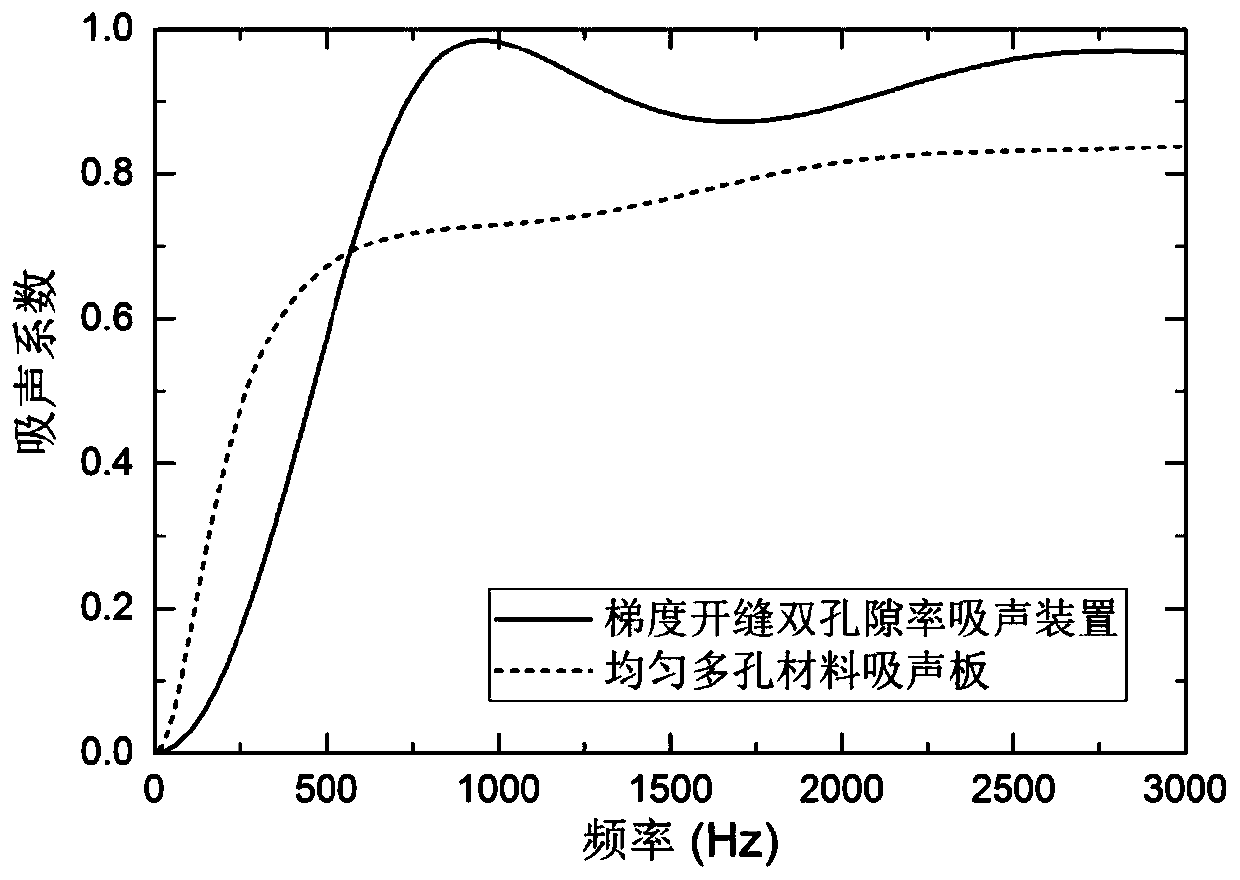

[0049] Set the slit widths at both ends of the gradient slit in Example 1 to 6 mm and 2 mm, and select the slit type as trumpet type. Other structural parameters and base porous material remain unchanged, and the placement method is also unchanged. At this time, the slit rate is 7.3%. . The sound absorption coefficient of embodiment 3 is referring to Figure 4 . Compared with the uniform porous material plate without slits of the same base material and the same thickness, the structure of this embodiment can appear the sound absorption peak earlier at the frequency of 550 Hz, and achieve enhanced sound absorption in the range above 290 Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com