A low-frequency sound-absorbing needle-punched nonwoven composite material and its preparation method and application

A composite material and non-woven technology, which is applied in the direction of sound-emitting devices, instruments, building components, etc., can solve the problems of poor low-frequency sound absorption performance, and achieve improved low-frequency sound absorption performance, good sound absorption performance, and excellent low-frequency sound absorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

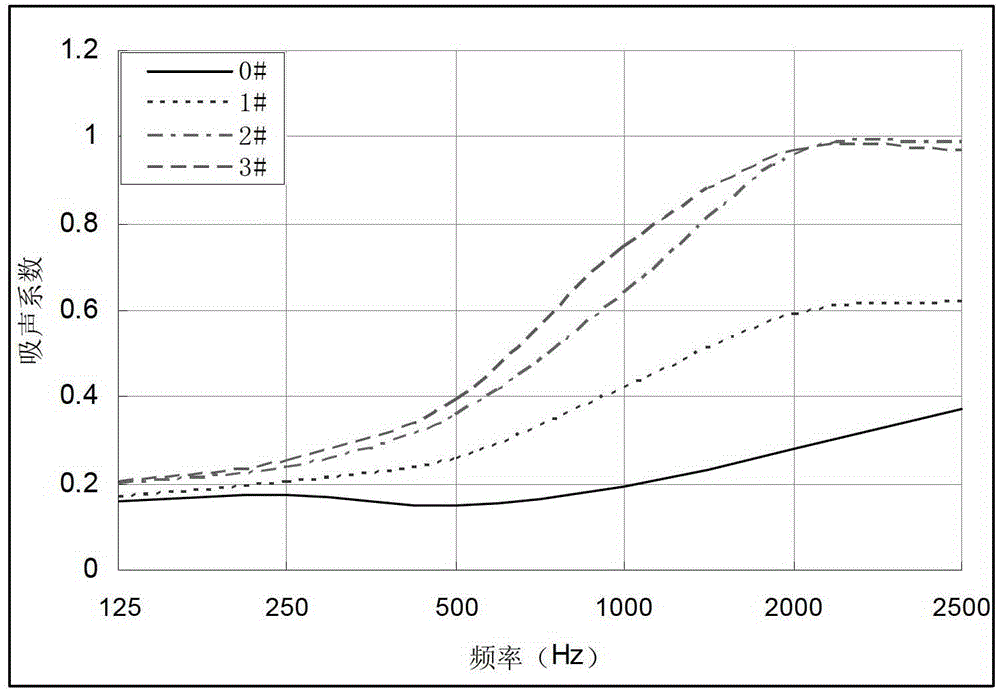

[0028] According to the mass percentage, 90% of the kapok fiber and 10% of the hollow polyester fiber are mixed, opened, carded, formed into a web, reinforced with needles, wound, and cut to obtain the kapok fiber / hollow polyester nonwoven fabric. The nonwoven fabric has a thickness of 1cm and a bulk density of 190g / m 2 .

Embodiment 2

[0030] According to the mass percentage, 90% of the kapok fiber and 10% of the hollow polyester fiber are mixed, opened, carded, formed into a web, reinforced with needles, wound, and cut to obtain the kapok fiber / hollow polyester nonwoven fabric. The nonwoven fabric has a thickness of 3cm and a bulk density of 387g / m 2 .

Embodiment 3

[0032] According to the mass percentage, 90% of the kapok fiber and 10% of the hollow polyester fiber are mixed, opened, carded, formed into a web, reinforced with needles, wound, and cut to obtain the kapok fiber / hollow polyester nonwoven fabric. The nonwoven fabric has a thickness of 3cm and a bulk density of 387g / m 2 . Put a polyethylene film with a thickness of 0.08mm flatly on one side of the above-mentioned non-woven fiber web, and put them together in an oven to raise the temperature (110-130°C); take out the material and cool it down.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com